Inflatable thermal forming method and forming die for vertical pipe

A thermoforming and inflatable technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as restricting the popularization and application of inflatable forming of pipes, thinning of wall thickness of formed parts, unstable forming temperature, etc. Achieve the effect of solving the unstable forming temperature, ensuring the forming internal pressure, and accurately controlling the forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

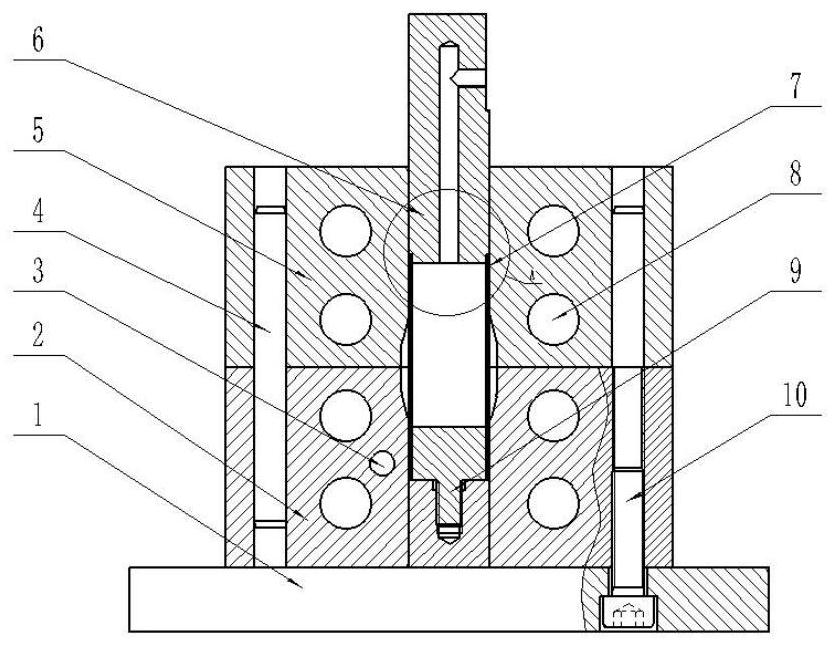

[0056] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

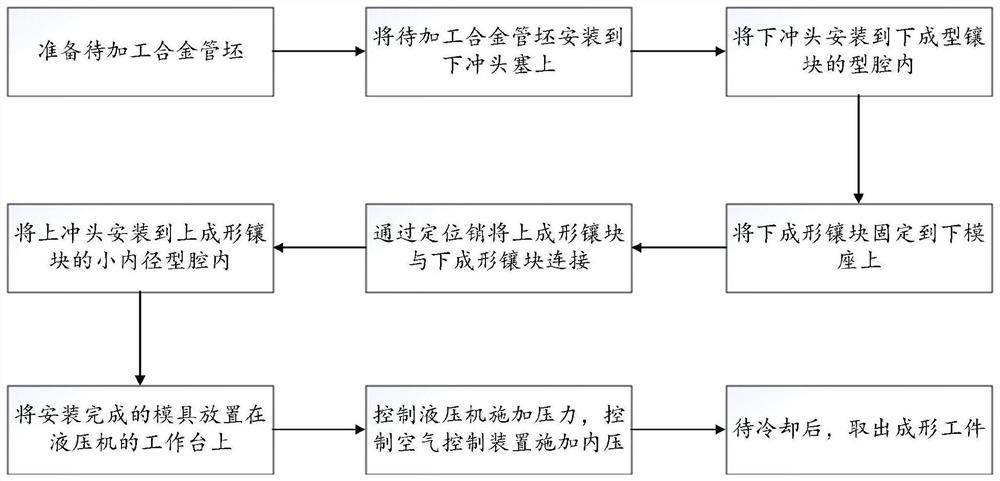

[0057] Such as figure 1 As shown, the inflatable thermoforming method for vertical pipes is processed by inflating the alloy tube blank 7 to be processed to obtain a formed hollow part. The specific steps are as follows:

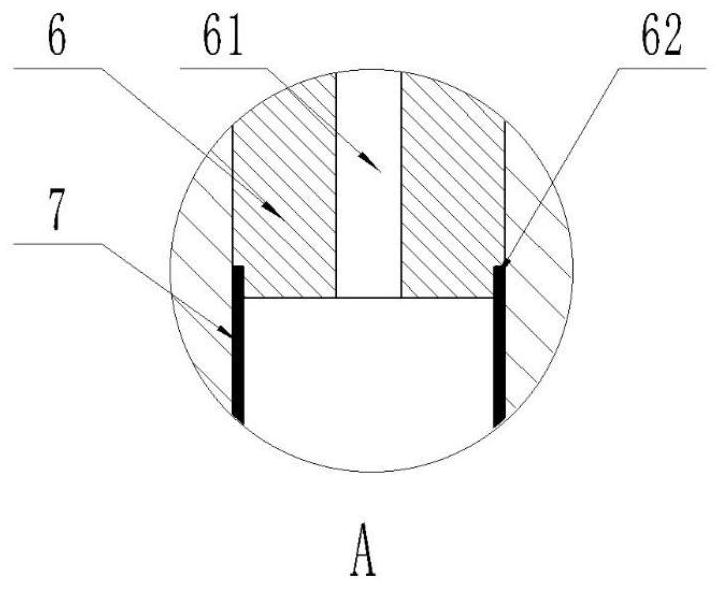

[0058] S1. Initially preload the upper punch 6 and the lower punch 9 respectively. The initial preload can ensure that the inner diameter matching surface of the alloy tube billet 7 to be processed will not be significantly damaged, and prevent the alloy tube to be processed from being damaged when the hydraulic press is preloaded. Obvious scratches occurred on the mating surface of the inner diameter of billet 7 .

[0059] S2. Connect the upper forming insert 5 and the lower forming insert 2 through the positioning pin 4, so that the cavity surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com