Palladium-catalyzed N-H carbonylation reaction of N-phenylpyridine-2-amine by taking DMF (Dimethyl Formamide) as methyl source

A carbonylation reaction and phenylpyridine technology, applied in the field of medicinal chemistry, can solve the problems of harsh reaction conditions and limited applicability of substrates, and achieve the effects of easy availability of raw materials, excellent yield, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

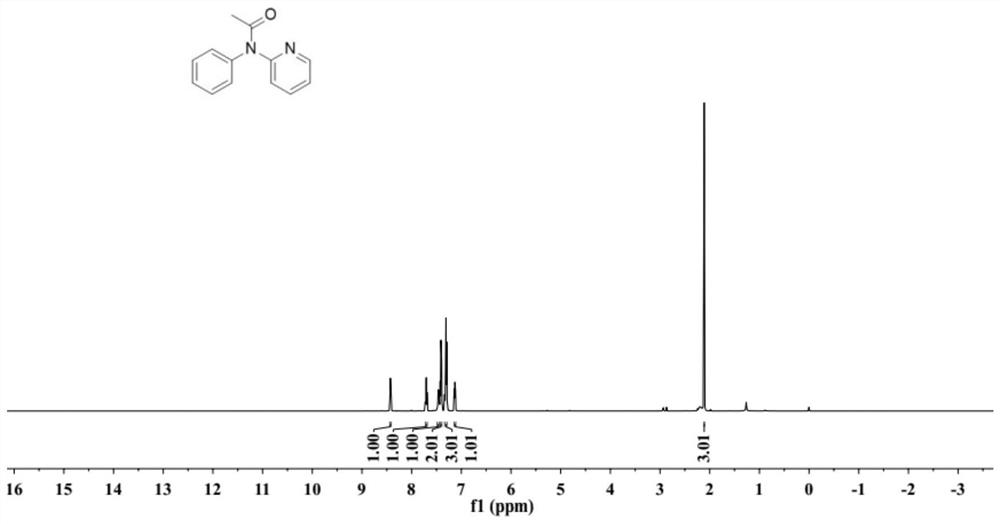

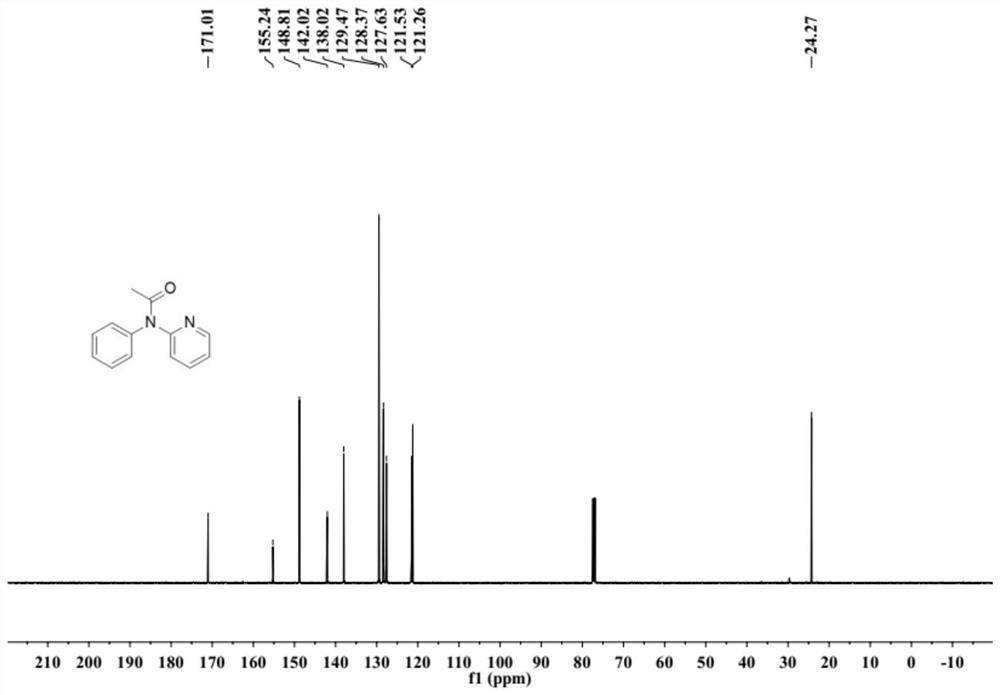

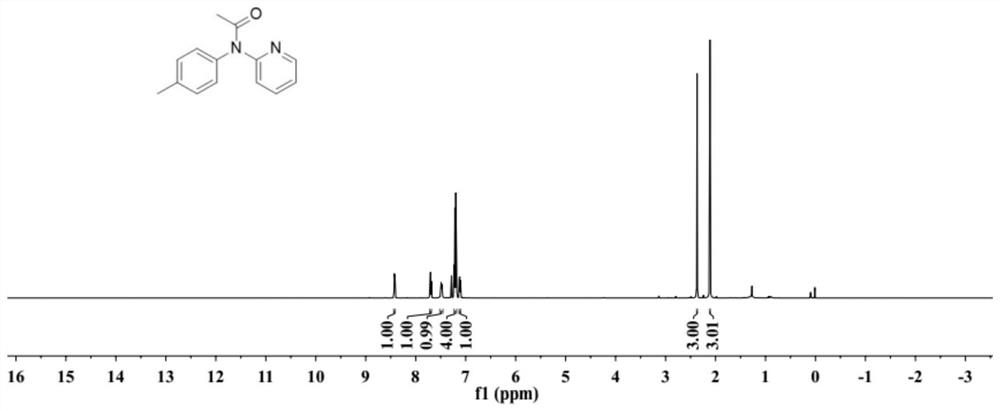

Embodiment 1

[0031] Add 0.2 mmol of N-phenylpyridin-2-amine, 0.03 mmol of palladium acetate, 0.22 mmol of copper acetate, and 0.04 mmol of potassium iodide into a 25 mL test tube, add N,N-dimethylformamide (DMF)3 mL as a solvent, put a balloon containing carbon monoxide gas as a carbonyl source, and stir at 100 degrees Celsius. After the TLC (thin layer chromatography) detection reaction, the reaction solution was cooled to room temperature, the balloon was removed, and the unreacted carbon monoxide was slowly vented. The reaction solution was filtered, and the filtrate was rotary evaporated under reduced pressure to remove the solvent, and then separated and purified by column chromatography to obtain the target product with a yield of 30%.

Embodiment 2

[0033] Add 0.2 mmol of N-phenylpyridin-2-amine, 0.03 mmol of palladium trifluoroacetate, 0.22 mmol of copper acetate, 0.04 mmol of potassium iodide into a 25 mL test tube, add N,N-dimethylformamide (DMF ) 3 ml as a solvent, put a balloon containing carbon monoxide gas as a carbonyl source, and stir at 100 degrees Celsius. After the TLC (thin layer chromatography) detection reaction, the reaction solution was cooled to room temperature, the balloon was removed, and the unreacted carbon monoxide was slowly vented. The reaction solution was filtered, and the filtrate was rotary evaporated under reduced pressure to remove the solvent, and then separated and purified by column chromatography to obtain the target product with a yield of 25%.

Embodiment 3

[0035] Add 0.2 millimoles of N-phenylpyridin-2-amine, 0.03 millimoles of palladium dichlorodiacetonitrile, 0.22 millimoles of copper acetate, 0.04 millimoles of potassium iodide, and add N,N-dimethylformamide ( DMF) 3 ml as a solvent, covered with a balloon containing carbon monoxide gas as a carbonyl source, stirred at 100 degrees Celsius. After the TLC (thin layer chromatography) detection reaction, the reaction solution was cooled to room temperature, the balloon was removed, and the unreacted carbon monoxide was slowly vented. The reaction solution was filtered, and the filtrate was rotary evaporated under reduced pressure to remove the solvent, and then separated and purified by column chromatography to obtain the target product with a yield of 32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com