Preparation method of corrosion-resistant cerium-containing Zn-Cu-Ti coating

A technology of zn-cu-ti and zn-cu-ti-ce is applied in the field of preparation of corrosion-resistant cerium-containing Zn-Cu-Ti coatings, which can solve the problems of unclear coating morphology and unclear influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

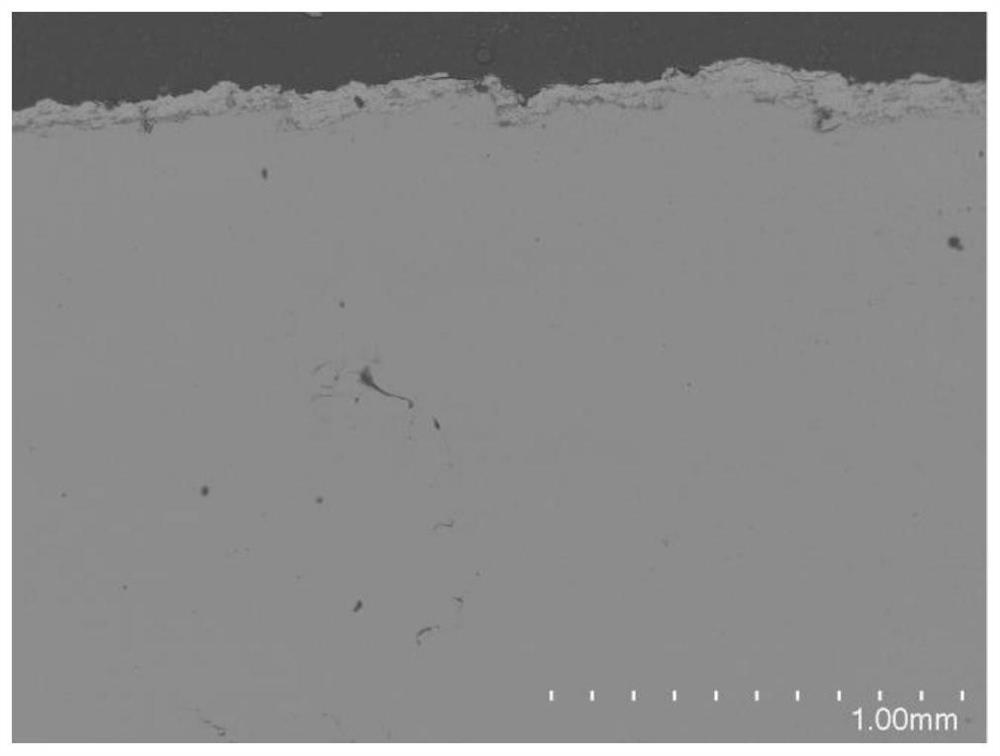

Embodiment 1

[0024] A method for preparing a corrosion-resistant cerium-containing Zn-Cu-Ti coating, comprising the following steps:

[0025] (1) Select high-quality sponge titanium and pure copper particles as raw materials for a ratio of 1:1, and use a vacuum arc melting furnace with electromagnetic stirring conditions for melting to prepare a Cu-50Ti master alloy.

[0026] (2) Using pure copper particles, pure zinc and pure cerium as raw materials, Zn-10Cu and Zn-3Ce master alloys are prepared by using a resistance furnace, the melting temperature is 650 ° C, the holding time is not less than 5 hours, and several times are stirred during the holding process .

[0027] (3) With pure Zn, Cu-50Ti, Zn-10Cu and Zn-3Ce intermediate alloy as raw materials, utilize resistance furnace to prepare Zn-0.75Cu-0.15Ti-0.1Ce immersion plating solution, first Zn block is melted during smelting, selected The temperature is about 650°C. After the Zn block is completely melted, the master alloy is added a...

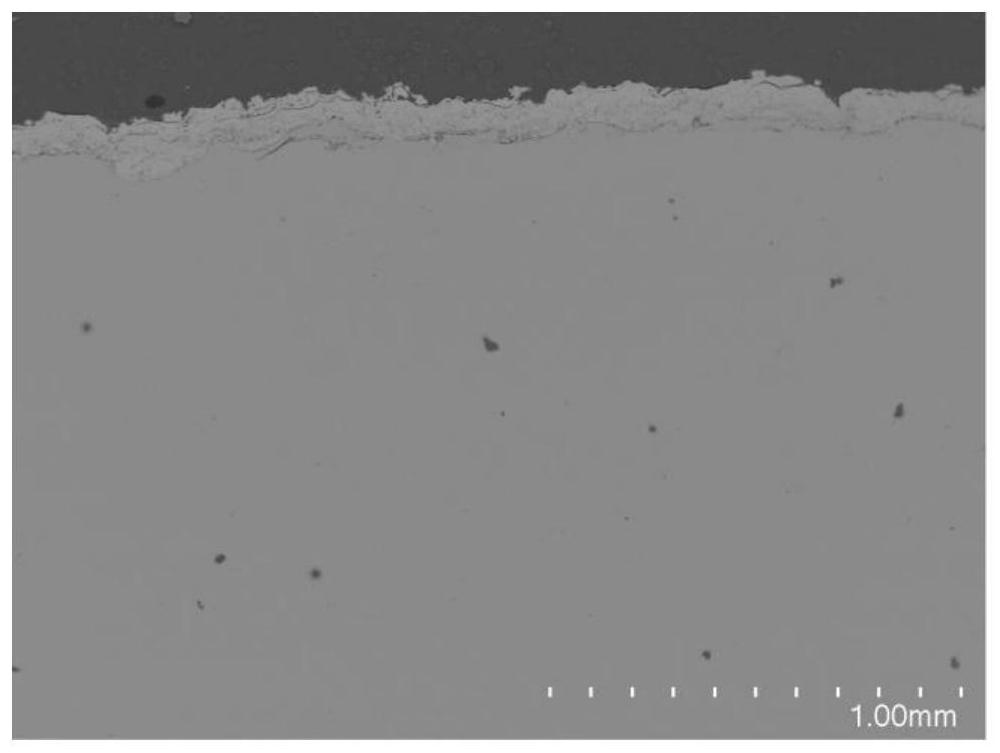

Embodiment 2

[0031] A method for preparing a corrosion-resistant cerium-containing Zn-Cu-Ti coating, comprising the following steps:

[0032] (1) Select high-quality sponge titanium and pure copper particles as raw materials for a ratio of 1:1, and use a vacuum arc melting furnace with electromagnetic stirring conditions for melting to prepare a Cu-50Ti master alloy.

[0033] (2) Using pure copper particles, pure zinc and pure cerium as raw materials, Zn-10Cu and Zn-3Ce master alloys are prepared by using a resistance furnace, the melting temperature is 650 ° C, the holding time is not less than 5 hours, and several times are stirred during the holding process .

[0034] (3) With pure Zn, Cu-50Ti, Zn-10Cu and Zn-3Ce intermediate alloy as raw materials, utilize resistance furnace to prepare Zn-0.75Cu-0.15Ti-0.2Ce immersion plating solution, first Zn block is melted during smelting, selected The temperature is about 650°C. After the Zn block is completely melted, the master alloy is added a...

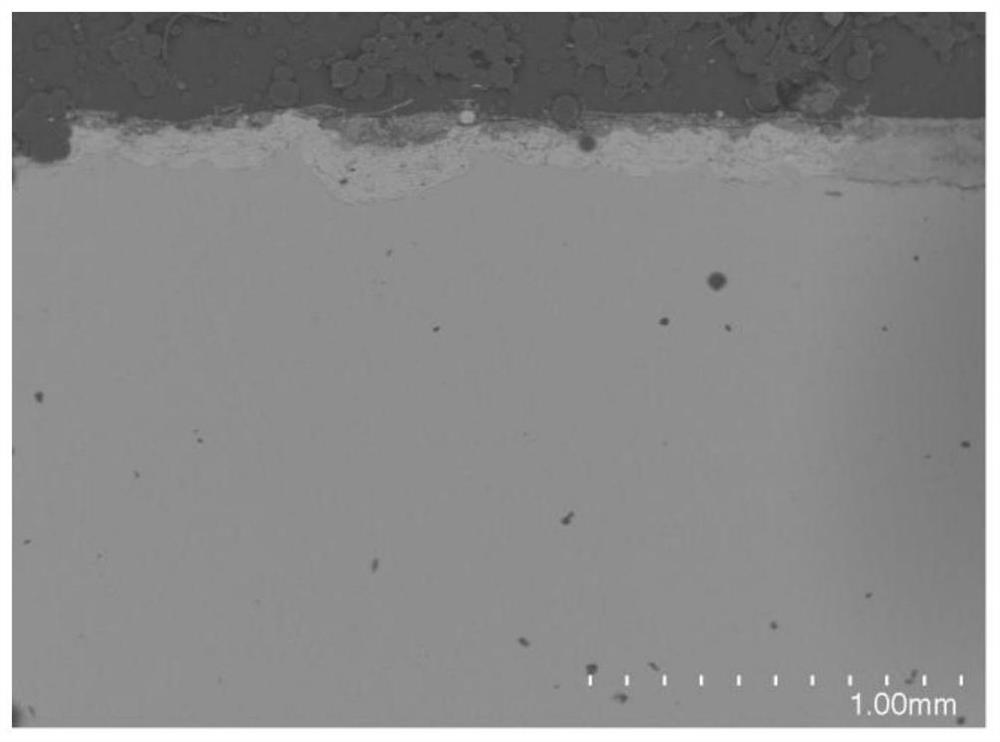

Embodiment 3

[0038] A method for preparing a corrosion-resistant cerium-containing Zn-Cu-Ti coating, comprising the following steps:

[0039] (1) Select high-quality sponge titanium and pure copper particles as raw materials for a ratio of 1:1, and use a vacuum arc melting furnace with electromagnetic stirring conditions for melting to prepare a Cu-50Ti master alloy.

[0040] (2) Using pure copper particles, pure zinc and pure cerium as raw materials, Zn-10Cu and Zn-3Ce master alloys are prepared by using a resistance furnace, the melting temperature is 650 ° C, the holding time is not less than 5 hours, and several times are stirred during the holding process .

[0041](3) With pure Zn, Cu-50Ti, Zn-10Cu and Zn-3Ce intermediate alloy as raw materials, utilize resistance furnace to prepare Zn-0.75Cu-0.15Ti-0.3Ce immersion plating solution, first Zn block is melted during smelting, selected The temperature is about 650°C. After the Zn block is completely melted, the master alloy is added an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com