Device and method for evaluating explosion risk of sulphide ore dust

A technology for hazardous and sulfide minerals, applied in measurement devices, instruments, analysis of suspensions and porous materials, etc., can solve problems such as quantitative evaluation of potential hazards of dust explosions, and reduce errors, improve accuracy, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

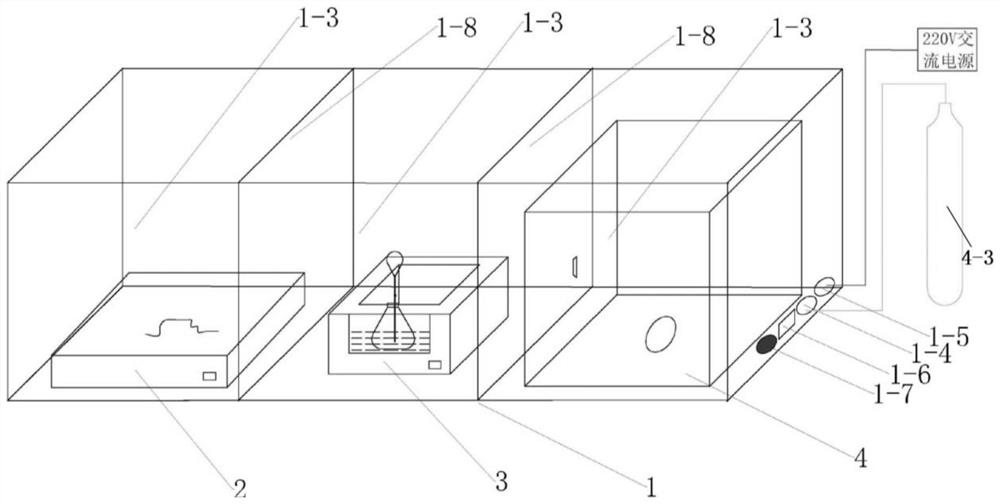

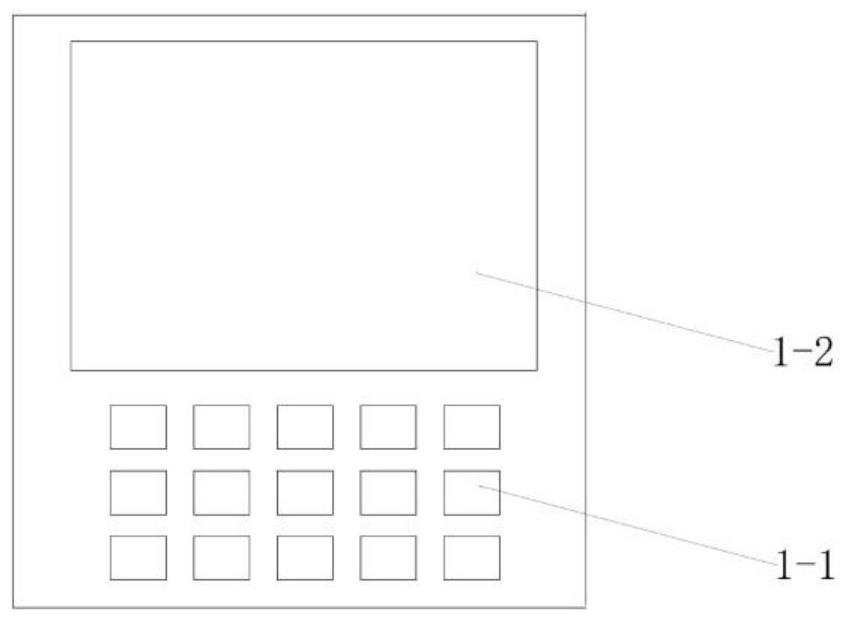

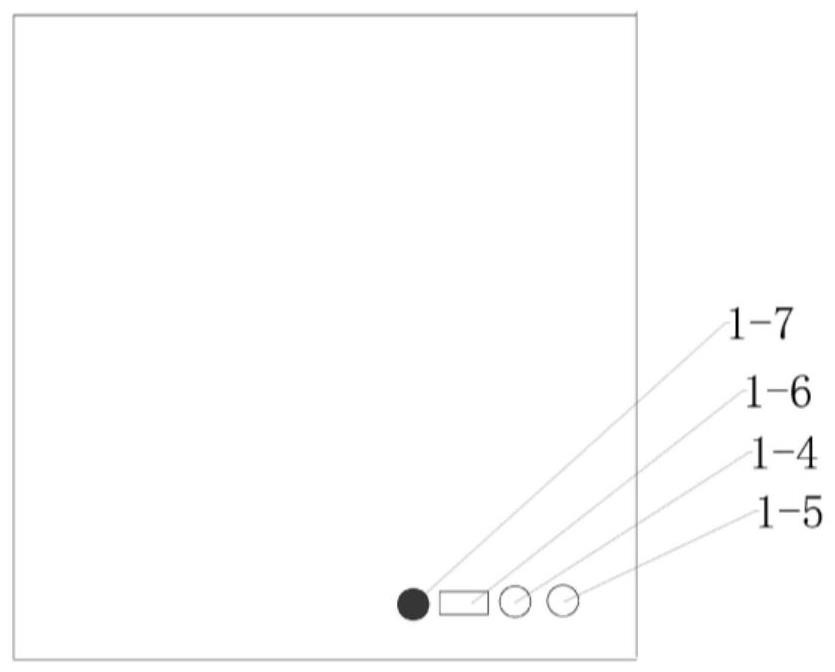

[0060] Such as Figure 1 to Figure 7 As shown, the device used in this embodiment for risk assessment of sulfide mine dust explosion includes a box body 1, and an ignition temperature test unit 2, an oxidation rate test unit 3, and a dust diffusion test unit are arranged in the box body 1 in sequence from left to right. Unit 4;

[0061] The ignition temperature testing unit 2 includes a heating table 2-1, and a table temperature probe 2-2, a sample temperature probe 2-3 and a first heating controller 2-4 arranged on the heating table 2-1;

[0062] The oxidation rate testing unit 3 includes a constant temperature oil bath 3-1 and an Erlenmeyer flask 3-2 placed in the constant temperature oil bath 3-1, and an oxygen concentration detection probe 3 is arranged in the Erlenmeyer flask 3-2 -3, and the mouth of the Erlenmeyer flask 3-2 is sealed and communicated with the expansion gas collection bag 3-4, and the constant temperature oil bath box 3-1 is provided with a heating mediu...

Embodiment 2

[0076] Such as Figure 8 As shown, this embodiment includes the following steps:

[0077] Step 1. Open three independent and transparent chamber doors 1-3 in the device for risk assessment of sulfide ore dust explosion, respectively, to the heating table 2-1 in the ignition temperature test unit 2 and the conical chamber in the oxidation rate test unit 3. Add the 1# sulfide ore dust sample of 30g, 36g, and 30g respectively in the dust dispersing device 4-4 in the bottle 3-2 and the dust diffusion test unit 4, and then close each box door 1-3;

[0078] Step 2. Control the first heating controller 2-4 through the operation panel 1-1 so that the heating table 2-1 containing the sulfide ore dust sample in step 1 is heated up, and the heating table 2-1 is measured by the table temperature probe 2-2 respectively. 1 temperature T 1 , using the sample temperature probe 2-3 to measure the temperature T of the sulfide ore dust sample 2 , the measurement results show that T 2 =450°C,...

Embodiment 3

[0085] The difference between this embodiment and embodiment 1 is: the 2# sulfide ore dust sample is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com