Bottom anti-reflection layer and preparation method thereof

A bottom anti-reflection layer and anti-reflection technology, applied in the field of photoresist, can solve difficult problems and achieve the effects of eliminating standing waves, improving anti-reflection ability, and reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

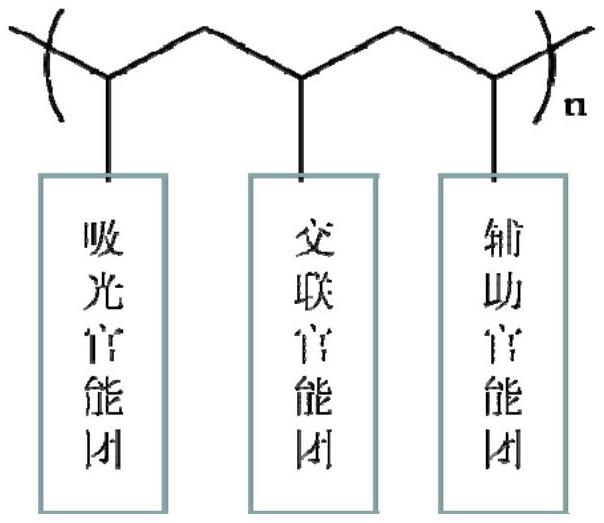

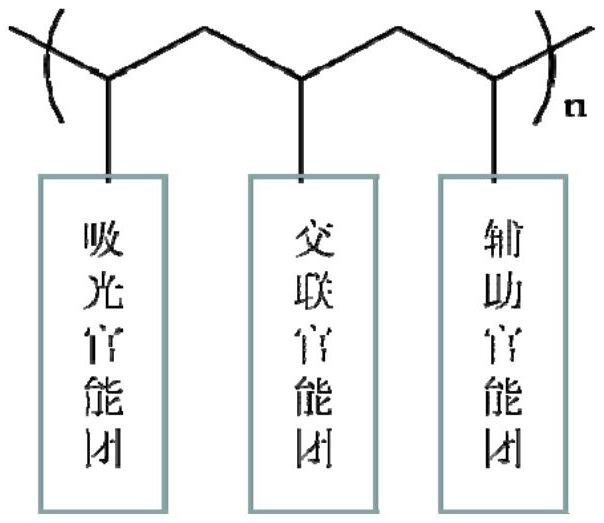

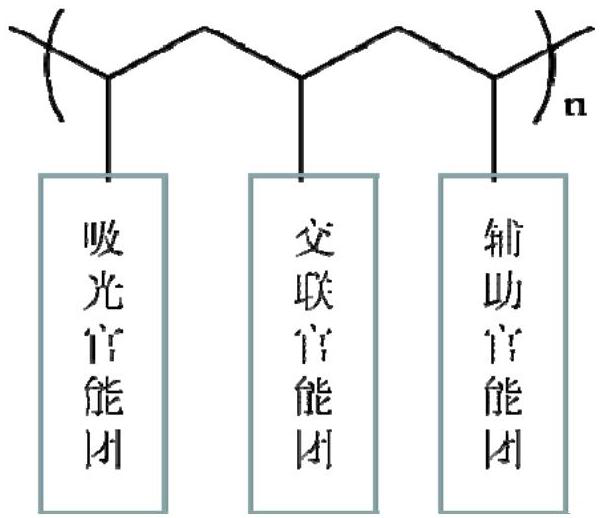

Method used

Image

Examples

preparation example Construction

[0031] In one embodiment, the preparation method of the bottom anti-reflection layer specifically includes the following steps:

[0032] Spin-coat the first light-absorbing film solution on a silicon wafer, spin at a speed of 2000-3000 r / min to form a film, and bake it on a hot plate at 150-250°C for 80-100s at the same time, and obtain the the first light absorbing film layer;

[0033] Spin-coat anti-reflection film solution on the first light-absorbing film layer, spin at a speed of 500-3000 r / min to form a film, and post-bake on a hot plate at 60-300°C for 90-300 s, and after cooling, the obtained the anti-reflection film layer;

[0034] Spin-coat the second light-absorbing film solution on the anti-reflection film layer, spin at a speed of 2000-3000 r / min to form a film, and bake it on a hot plate at 150-250°C for 80-100s at the same time. After cooling, the obtained solution is obtained. the second light absorbing film layer.

[0035] In one embodiment, the bottom anti...

Embodiment 1

[0051] A preparation method of a bottom anti-reflection layer, comprising the following steps:

[0052] Spin-coating the first light-absorbing film solution on a silicon wafer, and rotating at a speed of 2500 rpm to form a film, while baking on a hot plate at 200°C for 90s, and cooling to obtain the first light-absorbing film layer;

[0053] Spin-coating the anti-reflection film solution on the first light-absorbing film layer, and rotating at a speed of 2000 rpm to form a film, while post-baking on a 200°C hot plate for 200s, and cooling to obtain the anti-reflection film layer;

[0054] Spin-coat the second light-absorbing film solution on the anti-reflection film layer, spin at a speed of 2500 rpm to form a film, and bake it on a hot plate at 200°C for 90s at the same time, and obtain the second light-absorbing film layer after cooling .

[0055] The bottom anti-reflection layer prepared above had a refractive index of 1.81 and an extinction coefficient of 0.38.

[0056] ...

Embodiment 2

[0066] A preparation method of a bottom anti-reflection layer, comprising the following steps:

[0067] Spin-coating the first light-absorbing film solution on a silicon wafer, and rotating at a speed of 2000 rpm to form a film, while baking on a hot plate at 150° C. for 80s, and cooling to obtain the first light-absorbing film layer;

[0068] Spin-coat anti-reflection film solution on the first light-absorbing film layer, and rotate at a speed of 500 rpm to form a film, and at the same time post-bake on a 60°C hot plate for 90s, and obtain the anti-reflection film layer after cooling;

[0069] Spin-coat the second light-absorbing film solution on the anti-reflection film layer, spin at a speed of 2000 rpm to form a film, and bake it on a hot plate at 150°C for 80s at the same time, and obtain the second light-absorbing film layer after cooling .

[0070] The bottom anti-reflection layer prepared above had a refractive index of 1.85 and an extinction coefficient of 0.32.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com