Energy-saving double-cavity double-layer condensation evaporator for pure nitrogen equipment

A condensing evaporator and energy-saving technology, which is applied in the field of energy-saving double-chamber and double-layer condensing evaporators, can solve the problems of low liquid level, small heat transfer temperature difference of heat exchange units, mismatched diameters of rectifying towers, etc. cost, improve heat exchange efficiency, and the effect of wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

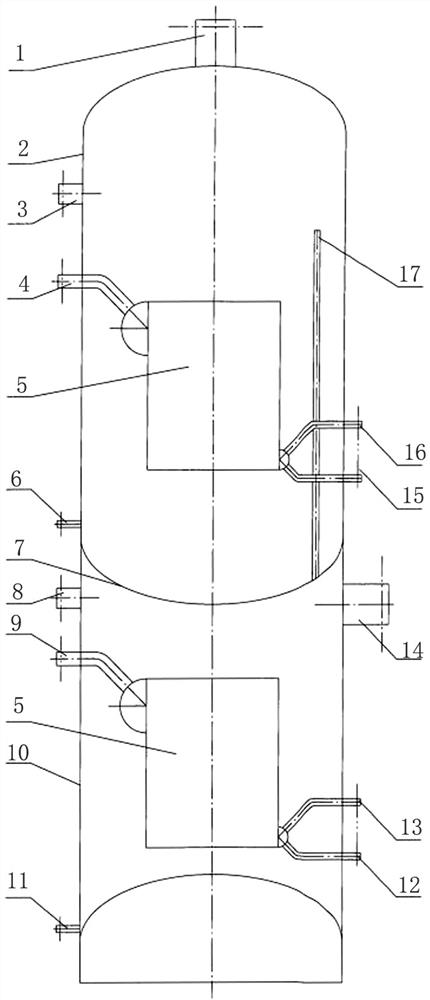

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the following in conjunction with the attached figure 1 , the present invention is introduced in detail. The invention provides a technical solution: an energy-saving double-cavity double-layer condensation evaporator for pure nitrogen equipment, which includes an evaporator cylinder, and the evaporator cylinder is composed of upper and lower layers of independent evaporator cylinders. The first and second layers of evaporation cylinders are separated by a partition head, and the size and structure of the first evaporation cylinder and the second evaporation cylinder are the same, and the first evaporation cylinder and the second evaporation cylinder The corresponding positions inside the body are respectively equipped with liquid air evaporation outlet 1, liquid air inlet 3, nitrogen inlet 4, liquid discharge port 6, condensate outlet 15, non-condensable gas outlet 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com