Novel main shaft broach mechanism with integrated pull claw

An integrated, claw-pulling technology, applied in the field of machine tool parts, can solve the problems of easy accumulation of water in the taper hole of the spindle, failure to achieve cooling effect, easy rust, etc., and achieve protection stability, small failure rate, and good dynamic balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

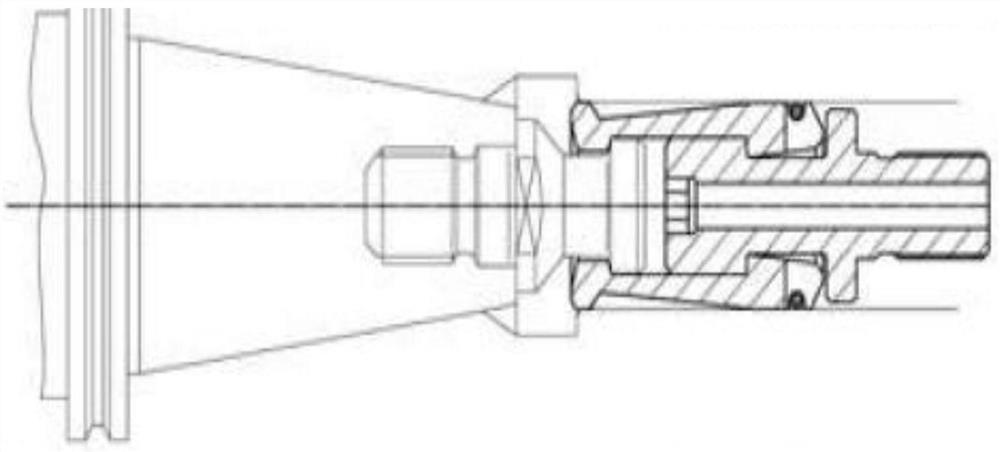

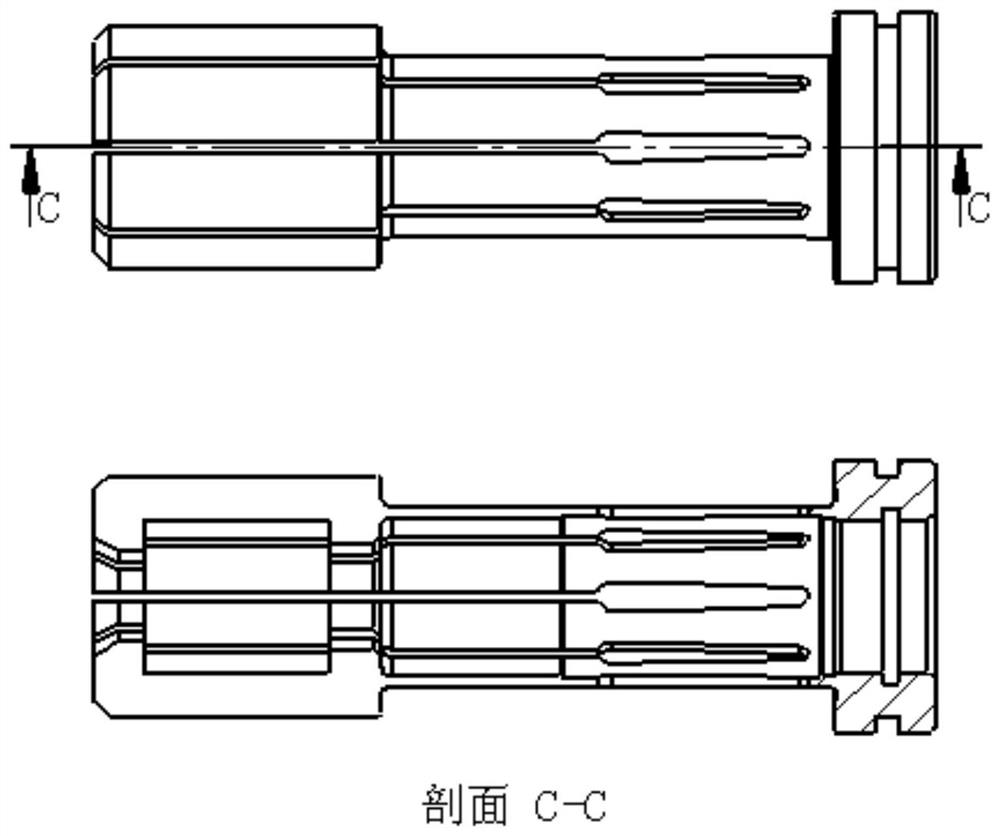

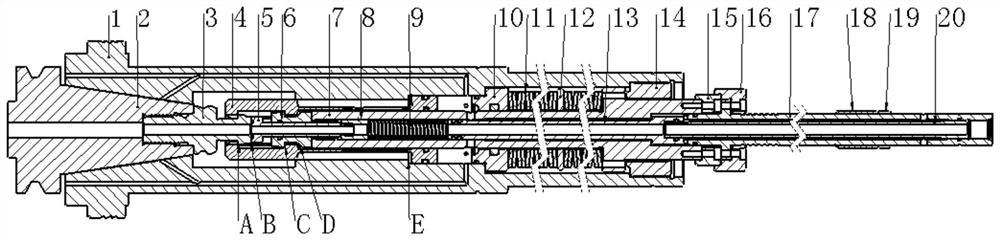

[0027] The present invention will be further described below with reference to the accompanying drawings.

[0028] In particular, in the specific implementation, in order to solve the above problem, the claw of the new type of pull-in mechanism is an integrated claw. The outer shape is as shown in Fig. -2, and the top of this new type can be divided into a front middle and third part, in which the front The two parts are divided into eight petals, and the latter portion is the entire outer diameter of the ring, the outer diameter of the latter portion is larger than the outer diameter of the first mid-end portion is divided into the entire portion, the outer portion of the intermediate portion is smaller than the front and rear parts, the inner diameter shape: overall Through holes, the integrated tip front end portion is a groove, between the intermediate portion and the front end portion;

[0029]The air source channel of the present invention is, the rotary coupling mounting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com