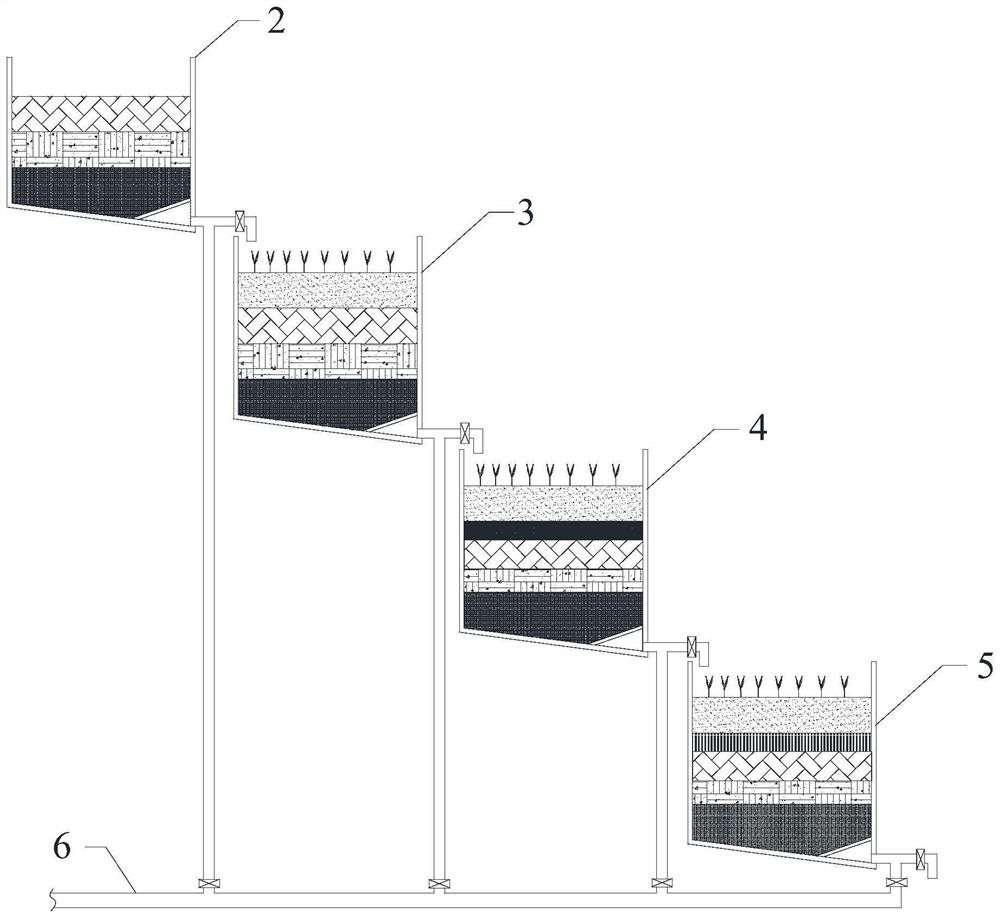

Sewage treatment system based on constructed wetland

A sewage treatment system and artificial wetland technology, applied in the direction of water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., to achieve good degradation, ensure treatment effect, and ensure normal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

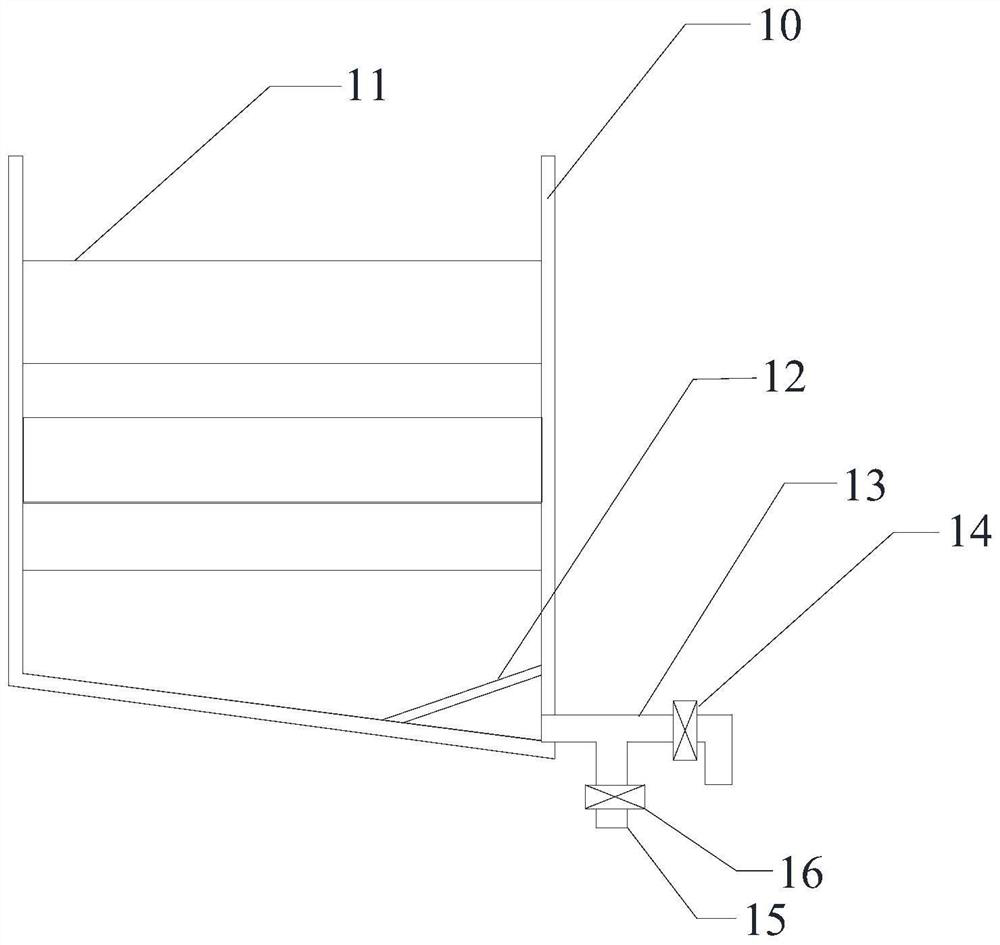

Method used

Image

Examples

Embodiment 1

[0037] 1.1 Preparation of modified ceramsite

[0038] S101. Grinding and pulverizing 12 parts of alumina, 30 parts of diatomaceous earth, 8 parts of zeolite and 3 parts of glass fiber powder in parts by weight;

[0039] S102. Mixing the pulverized materials evenly and then escaping from the granulator to prepare spherical blanks with a particle size of 6 mm;

[0040] S103. After drying the billet at 85°C for 1 hour, raise the temperature to 650°C at a rate of 5°C / min, then raise the temperature to 1200°C at a rate of 30°C / min for sintering for 50 minutes, and obtain modified ceramsite after cooling treatment.

[0041] 1.2 Preparation of manganese-loaded modified ceramsite

[0042] The modified ceramsite was immersed in potassium permanganate solution, soaked for 5 hours, and then calcined at 600° C. for 30 minutes to obtain the manganese-loaded modified ceramsite.

[0043] 1.3 Preparation of iron-loaded modified ceramsite

[0044] The modified ceramsite was immersed in the ...

Embodiment 2

[0051] 2.1 Preparation of modified ceramsite

[0052] S201. Grinding and pulverizing 15 parts of alumina, 25 parts of diatomaceous earth, 6 parts of zeolite and 2 parts of glass fiber powder in parts by weight;

[0053] S202. Mixing the pulverized materials evenly and then escaping from the granulator to prepare spherical blanks with a particle size of 6 mm;

[0054] S203. After drying the blank at 85°C for 1 hour, raise the temperature to 650°C at a rate of 5°C / min, then raise the temperature to 1100°C at a rate of 30°C / min for sintering for 50 minutes, and obtain modified ceramsite after cooling treatment.

[0055] 2.2 Preparation of manganese-loaded modified ceramsite

[0056] The modified ceramsite was immersed in potassium permanganate solution, soaked for 4 hours, and then calcined at 600° C. for 30 minutes to obtain manganese-loaded modified ceramsite.

[0057] 2.3 Preparation of iron-loaded modified ceramsite

[0058] The modified ceramsite was immersed in ferrous s...

Embodiment 3

[0065] 3.1 Preparation of modified ceramsite

[0066] S301. Grinding and pulverizing 13 parts of alumina, 26 parts of diatomaceous earth, 6 parts of zeolite and 3 parts of glass fiber powder in parts by weight;

[0067] S302. Mix the pulverized materials uniformly and then escape from the granulator to prepare spherical blanks with a particle size of 5 mm;

[0068] S303. After drying the billet at 80°C for 1 hour, raise the temperature to 650°C at a rate of 5°C / min, then raise the temperature to 1200°C at a rate of 30°C / min for sintering for 50 minutes, and obtain modified ceramsite after cooling treatment.

[0069] 3.2 Preparation of manganese-loaded modified ceramsite

[0070] The modified ceramsite was immersed in potassium permanganate solution, soaked for 4 hours, and then calcined at 600° C. for 30 minutes to obtain manganese-loaded modified ceramsite.

[0071] 3.3 Preparation of iron-loaded modified ceramsite

[0072] The modified ceramsite was immersed in the ferrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com