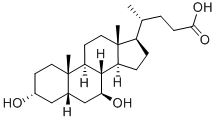

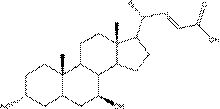

Purification method for removing 22-ene-UDCA impurity in ursodesoxycholic acid

A technology of 22-ene-udca and ursodeoxycholic acid, which is applied in the field of purification to remove 22-ene-UDCA impurities in ursodeoxycholic acid, and can solve the problem that the pharmaceutical effect of ursodeoxycholic acid is affected and the impurities are not good The removal method and other issues, to achieve the effect of low cost, convenient operation, and thorough purification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take 100g of ursodeoxycholic acid and pour it into a 2000ml flask, dissolve it in a solvent mixed with 800ml of n-butanol and 50ml of water, stir and dissolve it in an oil bath at 60°C; add 50g of potassium hydroxide solid to the flask , Distill under reduced pressure in a vacuum of 20kp, azeotropically distill for 20 minutes, remove the water in the solvent, and take a sample to determine that the residual water content of the solvent is about 0.3%; , stirred and reacted for 8 hours, terminated the reaction, thoroughly recovered the solvent by distillation under reduced pressure, added hydrochloric acid to adjust the pH value to 2-3, filtered with suction, separated, collected the solid in a decompression drying box, and detected it with ultraviolet liquid phase, and obtained no Ursodeoxycholic acid containing 22-ene-UDCA 98.4g.

Embodiment example 2

[0031] Take 100g of ursodeoxycholic acid and pour it into a 2000ml flask, and dissolve it in a solvent mixed with 1000ml of n-amyl alcohol and 90ml of water, stir and dissolve in an oil bath at 70°C; add 70g of potassium hydroxide solid to the flask, Distill under reduced pressure at a vacuum of 20kp, azeotropically distill for 20 minutes, remove the water in the solvent, and take a sample to determine that the residual water content of the solvent is about 0.2%; pour the solvent into a flask, place in an oil bath at 120°C, Stir the reaction for 9 hours, terminate the reaction, distill the solvent under reduced pressure and recover thoroughly, add hydrochloric acid to adjust the pH value to 2-3, filter with suction, separate, collect the solid in a decompression drying box, and detect it with ultraviolet liquid phase, and obtain 22-ene-UDCA ursodeoxycholic acid 98.7g.

Embodiment example 3

[0033] Get 100g of ursodeoxycholic acid and pour it into a 2000ml flask, and dissolve it in a solvent mixed with 1200ml of n-hexanol and 90ml of water, stir and dissolve in an oil bath at 80°C; add 80g of potassium hydroxide solid to the flask, Distill under reduced pressure at a vacuum of 20kp, azeotropically distill for 20 minutes, remove the water in the solvent, and take a sample to determine that the residual water content of the solvent is about 0.2%, pour the solvent into a flask, and stir in an oil bath at 130°C After reacting for 10 hours, the reaction was terminated, the solvent was distilled under reduced pressure and recovered thoroughly, hydrochloric acid was added to adjust the pH value to 2-3, suction filtration, separation, the solid was collected and placed in a decompression drying oven, and detected by ultraviolet liquid phase, the obtained 22-free -ene-UDCA ursodeoxycholic acid 98.5g.

[0034] It can be seen from the above examples that in the purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com