TPV (thermoplastic vulcanizate) material for vehicles as well as preparation method and application thereof

A technology for vehicles and raw materials, applied in the field of TPV materials for vehicles and its preparation, can solve problems such as constraints, achieve fast speed, improve mechanical properties at room temperature and high temperature, and reduce degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

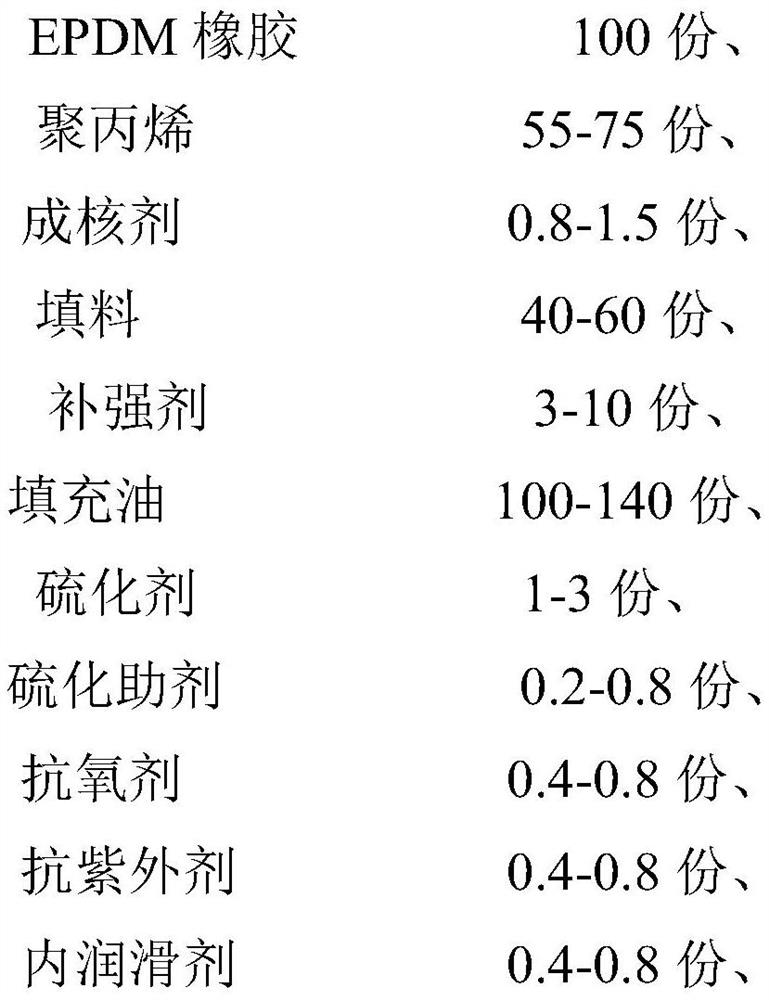

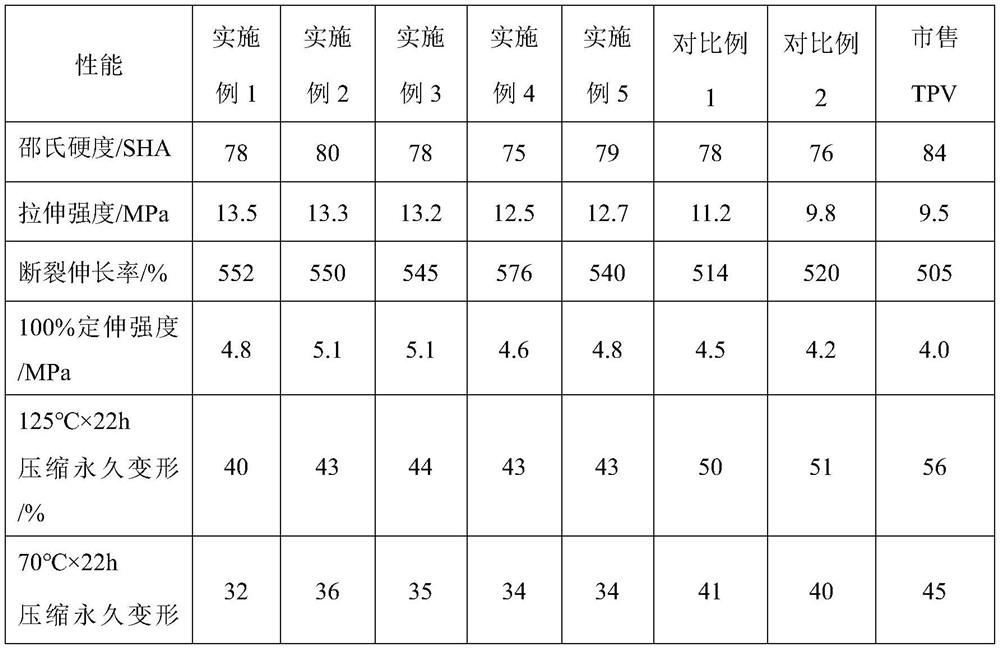

[0037] A kind of TPV material for vehicle, its raw material comprises by weight: 100 parts of EPDM rubber, 67 parts of polypropylene, 1.2 parts of nucleating agent, 50 parts of filler, 5 parts of reinforcing agent, 120 parts of filler oil, 2 parts of vulcanizing agent, 0.5 part of vulcanization aid, 0.6 part of antioxidant, 0.6 part of anti-ultraviolet agent, 0.5 part of internal lubricant.

[0038] EPDM is obtained by the copolymerization of ethylene, propylene, ethylidene norbornene ENB and 5-vinyl-2-norbornene VNB. When preparing EPDM rubber, ethylene, propylene, ENB and VNB respectively account for 50% and 50% of the total weight of comonomers. 46.5%, 0.5%, 3%.

[0039] Polypropylene is homopolypropylene with a density of 0.9g / cm 3 , The melt index is 12g / 10min.

[0040] The nucleating agent is 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol (commercially available product is referred to as nucleating agent 3988) and N,N-diphenylbutadiene Amides (DPS for short) are comb...

Embodiment 2

[0055] A kind of TPV material for vehicle, its raw material comprises by weight: 100 parts of EPDM rubber, 75 parts of polypropylene, 1.5 parts of nucleating agent, 45 parts of filler, 5 parts of reinforcing agent, 120 parts of filler oil, 2.4 parts of vulcanizing agent, 0.6 part of vulcanization aid, 0.6 part of antioxidant, 0.6 part of anti-ultraviolet agent, 0.5 part of internal lubricant.

[0056] EPDM rubber is obtained by copolymerization of ethylene, propylene, ethylidene norbornene ENB and 5-vinyl-2-norbornene VNB. When preparing EPDM rubber, ethylene, propylene, ENB and VNB respectively account for 62% of the total weight of comonomers , 35.4%, 0.6%, 2%.

[0057] Polypropylene is homopolypropylene with a density of 0.9g / cm 3 , The melt index is 15g / 10min.

[0058] The nucleating agent is a combination of 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol and N,N-diphenylsuccinamide at a mass ratio of 5:1.

[0059] The filler is superfine talc powder with a median part...

Embodiment 3

[0063] A kind of TPV material for vehicles, its raw material comprises by weight: 100 parts of EPDM, 75 parts of polypropylene, 1.5 parts of nucleating agent, 40 parts of filler, 10 parts of reinforcing agent, 140 parts of filler oil, 3 parts of vulcanizing agent, vulcanization assistant 0.8 parts of anti-oxidant, 0.8 parts of antioxidant, 0.6 parts of anti-ultraviolet agent, and 0.8 parts of internal lubricant.

[0064] EPDM is obtained by the copolymerization of ethylene, propylene, ethylidene norbornene ENB and 5-vinyl-2-norbornene VNB. When preparing EPDM rubber, ethylene, propylene, ENB and VNB respectively account for 50% and 50% of the total weight of comonomers. 46.5%, 0.5%, 3%.

[0065] Polypropylene is homopolypropylene with a density of 0.9g / cm 3 , The melt index is 10g / 10min.

[0066] The nucleating agent is a combination of 1,3:2,4-bis(3,4-dimethylbenzylidene)-D-sorbitol and N,N-diphenylsuccinamide in a weight ratio of 4:1.

[0067] The filler is superfine talc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com