Semiconductor device forming method

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve the problem of small hole etching ability, cannot meet the uniformity requirements of small-scale structure refinement process, cannot take into account the oxidation resistance of silicon nitride, etc. The uniformity of etching is high, the effect of improving CD shrinkage ability and enhancing etching selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

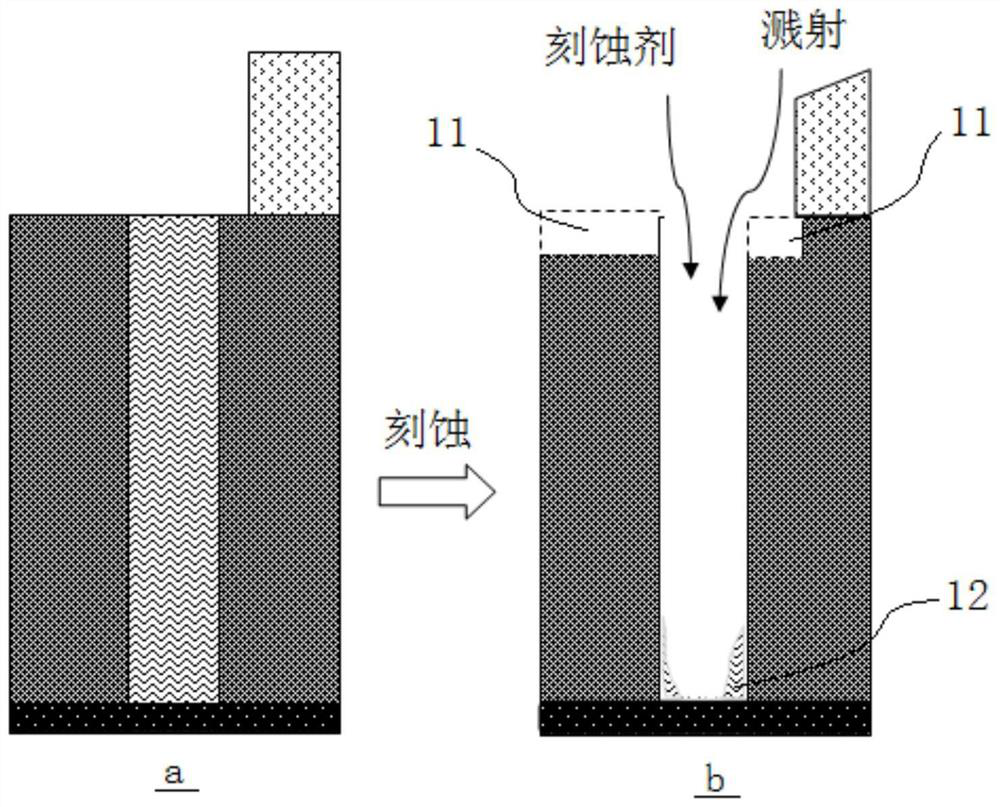

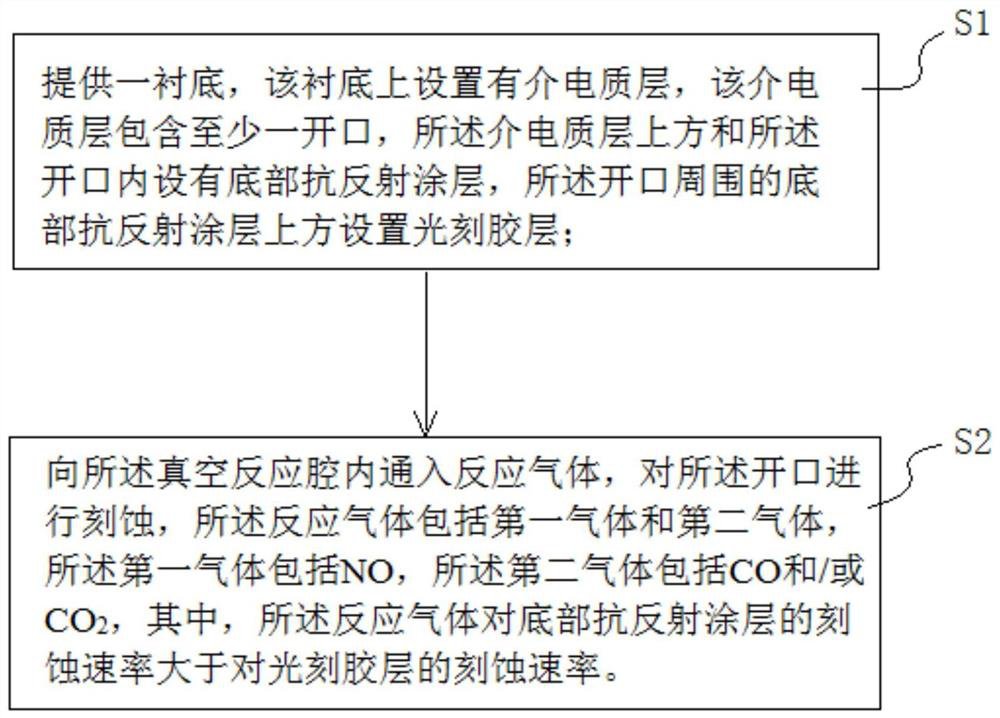

[0041] In the vacuum reaction chamber, a substrate is provided, and a dielectric layer is provided on the substrate, and the dielectric layer includes at least one opening, and a bottom anti-reflective coating is provided on the dielectric layer and in the opening. layer (BARC), a layer of photoresist (PR) is placed over the bottom anti-reflective coating around the opening.

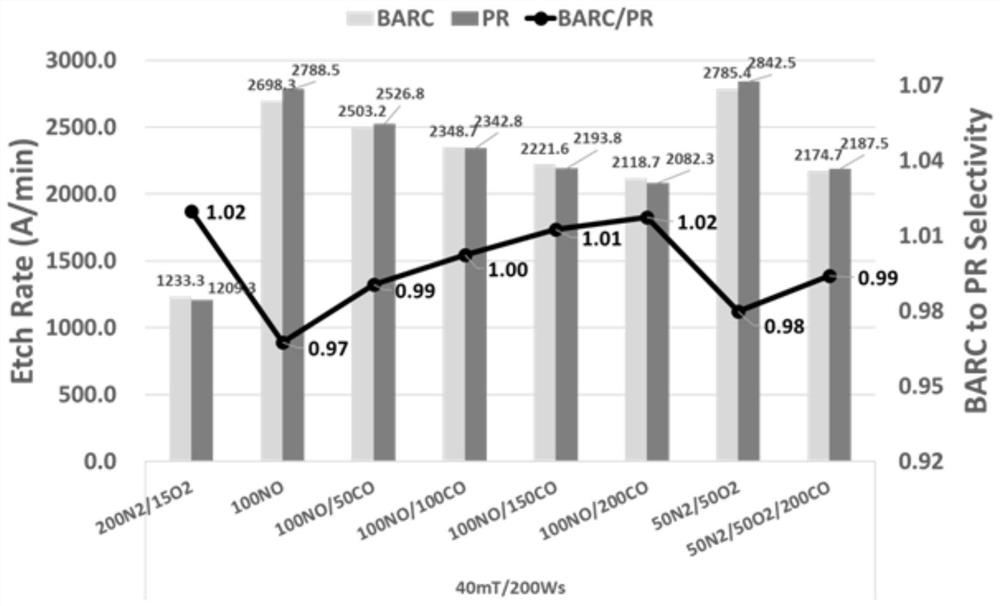

[0042] 100 units of NO were mixed with 0, 50, 100, 150 and 200 units of CO as the reaction gas to carry out the etching selectivity experiment of BARC and PR, that is, 100NO, 100NO / 50CO, 100NO / 100CO, 100NO / 150CO, 100NO / 200CO experimental group; use 200 units of N as a relatively good etching gas in the prior art 2 with 15 units of O 2 mixed as a reference group (200N 2 / 15O 2 ); and with 50N of equiatomic ratio 2 / 50O 2 , 50N 2 / 50O 2 / 200CO as a control group.

[0043] Experimental results such as image 3 shown, the reference group (200N 2 / 15O 2 ) The selection ratio of BARC and PR is 1.02...

Embodiment 2

[0048] In the vacuum reaction chamber, a substrate is provided, and a dielectric layer is provided on the substrate, and the dielectric layer includes at least one opening, and a bottom anti-reflective coating is provided on the dielectric layer and in the opening. layer (BARC), a layer of photoresist (PR) is placed over the bottom anti-reflective coating around the opening.

[0049] 100 units of NO were mixed with 0, 50, 100, 150 and 200 units of CO as the reaction gas to conduct etching rate and uniformity experiments on BARC coatings, namely, 100NO, 100NO / 50CO, 100NO / 100CO , 100NO / 150CO, 100NO / 200CO experimental groups; 50N with equiatomic ratio 2 / 50O 2 , 50N 2 / 50O 2 / 200CO as a control group.

[0050] Experimental results such as Figure 4 As shown, as the amount of CO increases, the etching rate decreases gradually, and the uniformity also decreases (NU% increases): the NU% of the experimental group increases from 2.2 to 4.2 (different processes require different N...

Embodiment 3

[0053] In the vacuum reaction chamber, a substrate is provided, and a dielectric layer is provided on the substrate, and the dielectric layer includes at least one opening, and a bottom anti-reflective coating is provided on the dielectric layer and in the opening. layer, a layer of photoresist is disposed over the bottom anti-reflective coating around the opening.

[0054] Using different reactive gases to etch the substrate, when etching the same thickness, the reference group conditions are: 200N 2 / 15O 2 Etching for 60s; the conditions of the control group were: 50N 2 / 50O 2 Etching 27s, 50N 2 / 50O 2 / 200CO etching for 35s; the experimental conditions were: 100NO etching for 28s, 100NO / 50CO etching for 30s, 100NO / 100CO etching for 32s, 100NO / 150CO etching for 34s, and 100NO / 200CO etching for 36s.

[0055] like Figure 5 As shown, after etching in the reference group, the CD size of PR is 87.28nm, and the etching rate is 1314.1A / min. A / min, the etching rate increased...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com