Spin coater with light path

A technology of glue homogenizer and optical path, which is applied in the direction of color/spectral characteristic measurement, device for coating liquid on the surface, coating, etc., can solve problems such as the inability to study the optical characteristics of organic semiconductor thin films, and achieve convenient real-time data analysis and guarantee The effect of precision, easy cleaning and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

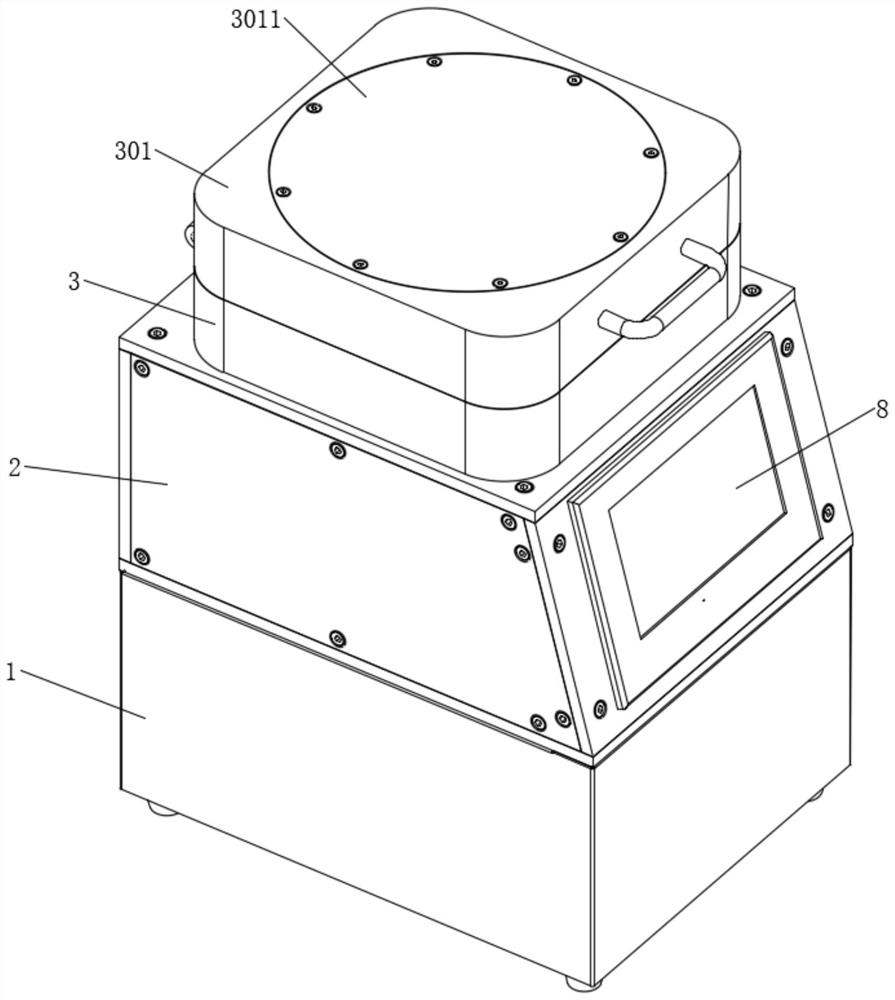

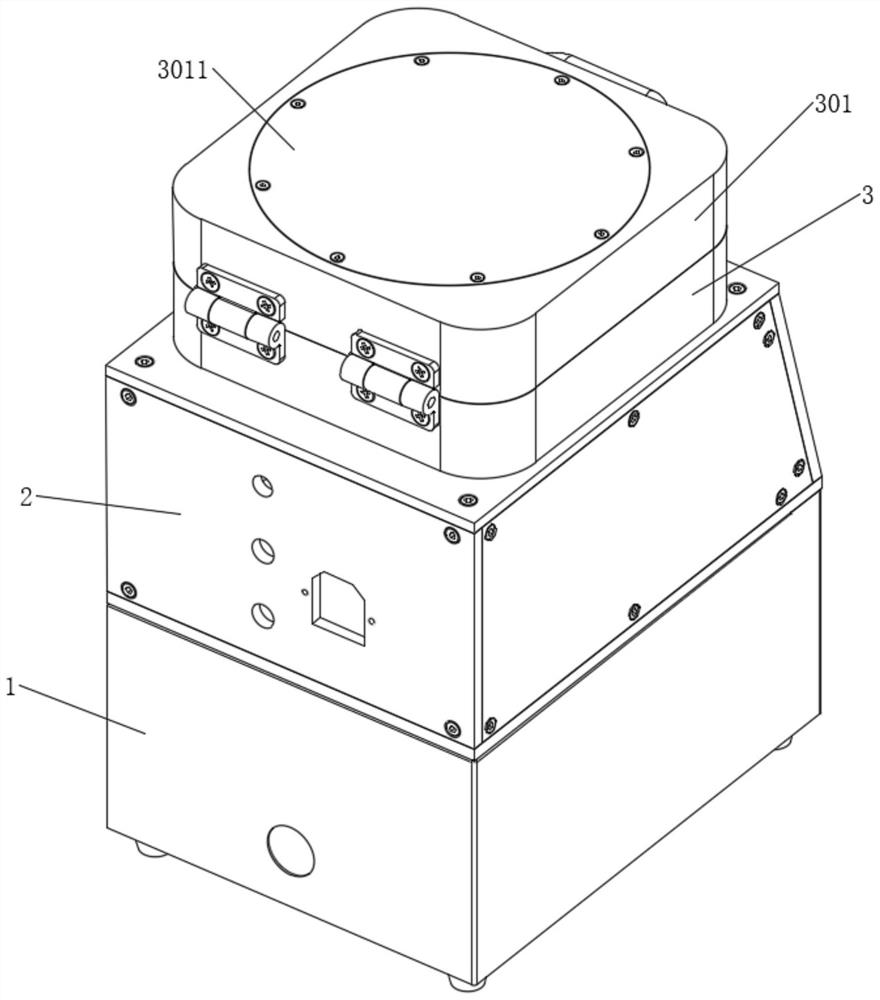

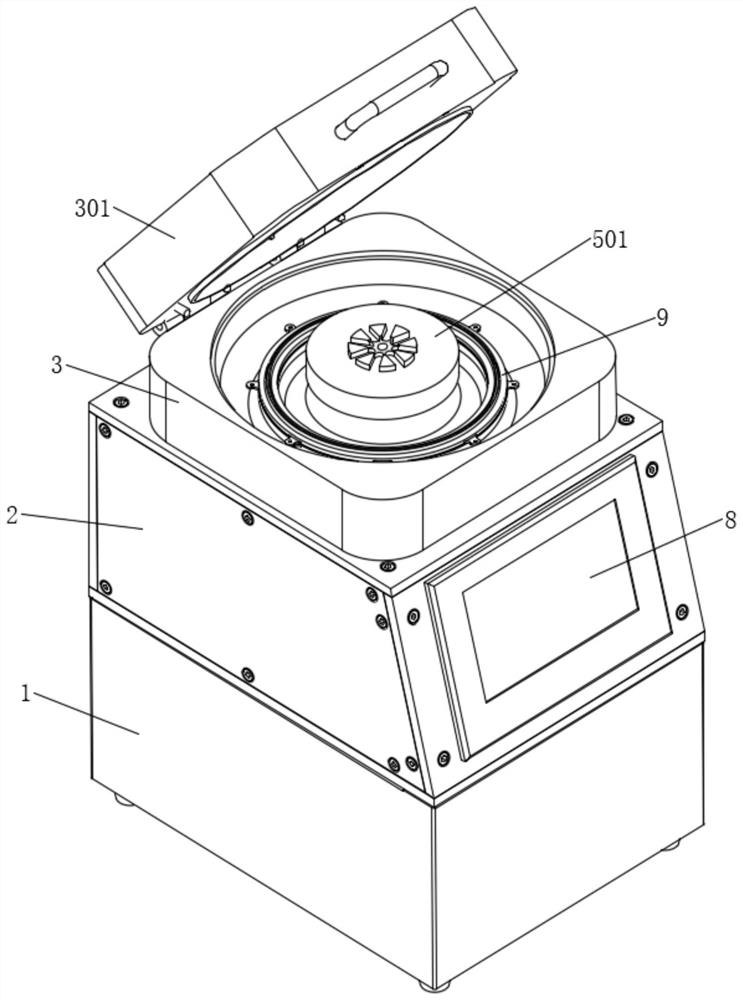

[0027] Please refer to Figure 1-Figure 6 , the present invention proposes a glue homogenizer with an optical path, including the glue homogenizer body, combined with figure 2 and Figure 4 As shown, the glue homogenizer body includes a first machine base 1, a second machine base 2 is fixed on the top of the first machine base 1, a coating film working base 3 is fixed on the top of the second machine base 2, and the coating film working base 3 One side is connected with an anti-splash top cover 301 through a pair of hinges, and the anti-splash top cover 301 is set on the upper port of the coating film working base 3 in cooperation with the cover, between the coating film working base 3 and the anti-splash top cover 301 A relatively closed working chamber is formed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com