Lithium bis (fluorosulfonyl) imide, preparation method of lithium bis (fluorosulfonyl) imide, electrolyte and secondary battery

A technology of lithium bisfluorosulfonimide and triethylamine, which is used in secondary batteries, circuits, electrical components, etc., can solve the problems of high moisture, three wastes, and low purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] 【Synthesis step→Evaporation step→Extraction step】

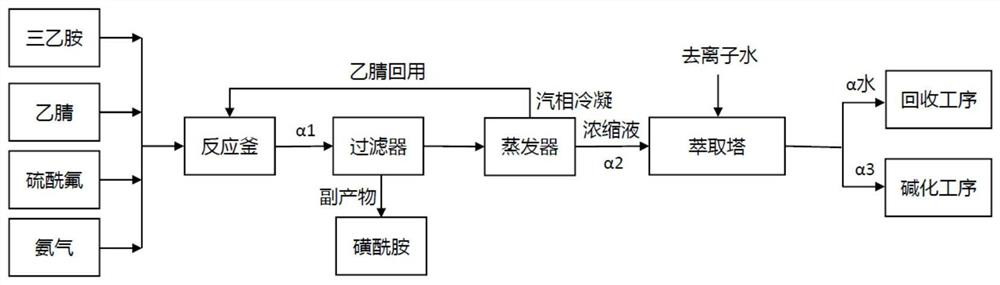

[0148] combine figure 1 To describe the α-stage process (synthesis→evaporation→extraction), where the extraction process uses an extraction tower.

[0149] will be 40m 3 Triethylamine, 35m 3 Acetonitrile is pumped into a volume of 100m 3 In the synthesis kettle, the temperature of the kettle is lowered to 15°C, then 120kg of ammonia gas is introduced first, and finally ammonia gas (2000kg) and sulfuryl fluoride (26000kg) are simultaneously introduced to keep the pressure in the kettle at 0.3MPa, and the The temperature was maintained at 15°C. After continuing the reaction for 4 h, the pressure in the kettle was reduced to 0.1 MPa, and the stirring was stopped. The obtained reaction mixture stream α1 (which contains 40% by weight of (SO 2 F-NH-SO 2 F)·Et 3 N, 18% by weight of triethylamine hydrogen fluoride and 6% by weight of triethylamine) are filtered through a tetrafluoro filter bag with a pore size of 5 μm ...

Embodiment 2

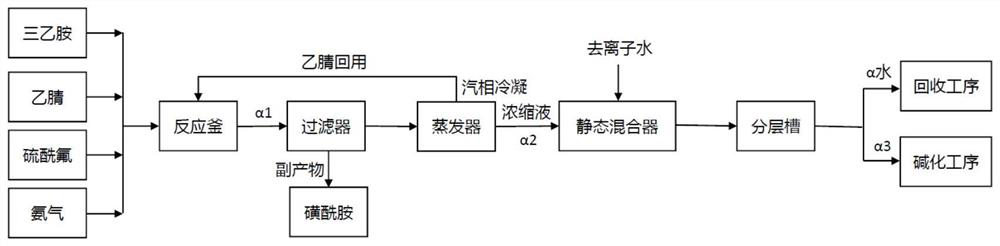

[0159] Embodiment 2: the technical scheme of embodiment 2 is identical with embodiment 1, difference is, in extraction step, what extraction process adopted is static mixer (the ratio L / D=10 of length and pipe diameter; Control flow makes deionization The weight ratio of water to α2 is 1:1.2). according to figure 2 As shown, the material flow α2 is pumped to the static mixer, and after being fully mixed with deionized water in the static mixer, it is sent to the stratification tank, and after standing for 2 hours, triethylamine-containing hydrogen fluoride is obtained as the supernatant Aqueous phase of salt alpha 水 , and containing (SO 2 F-NH-SO 2 F)·Et 3 The oil phase α3 of N, the upper water phase is sent to the recovery workshop for processing, and the lower oil phase is sent to the alkalization step. After testing, the α3 oil phase contains 1000ppm of F - .

[0160] After testing, the purity of the powder obtained by drying the above-mentioned lithium bisfluorosul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com