Sensing type crack sensing material as well as preparation method and application thereof

A sensing material and sensing technology, applied in instruments, sustainable waste treatment, solid waste management, etc., can solve the problems of easy damage, controlled physical and chemical properties, large brittleness, etc. The effect of damage, precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

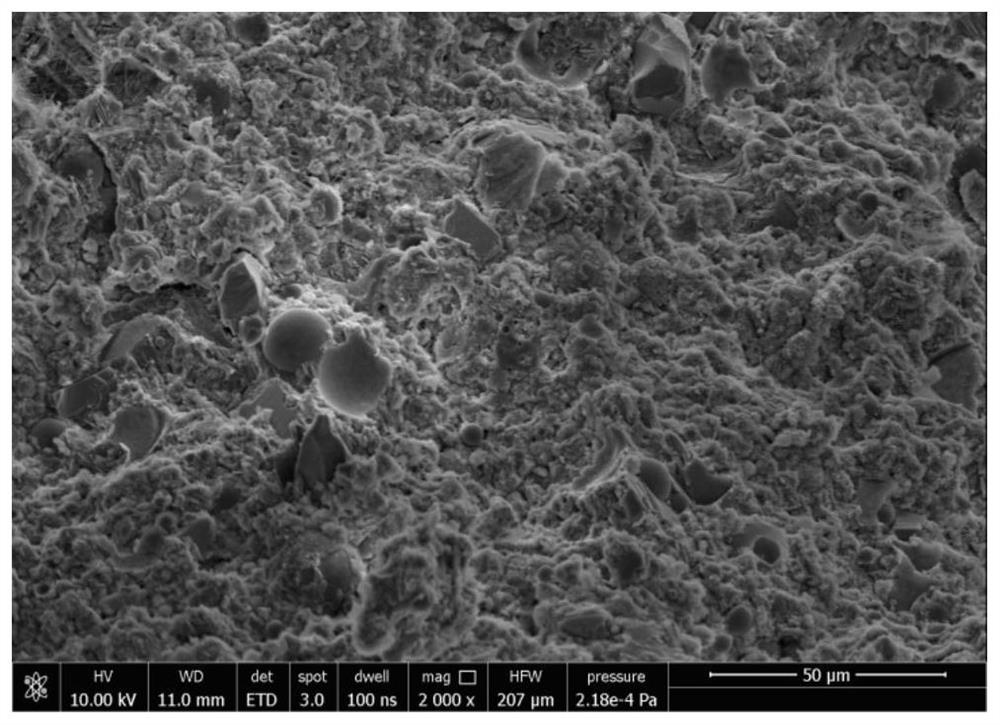

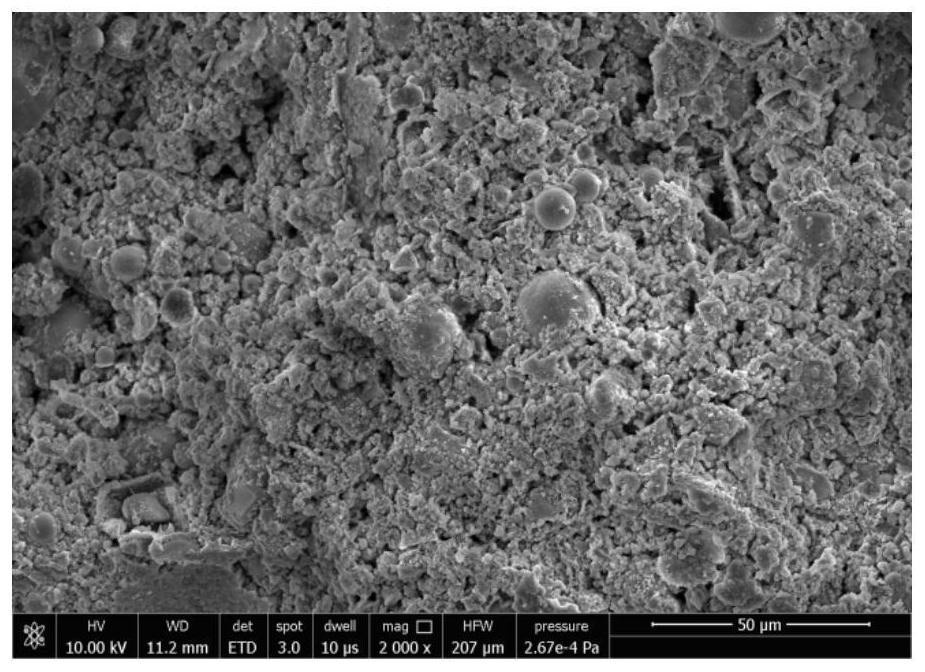

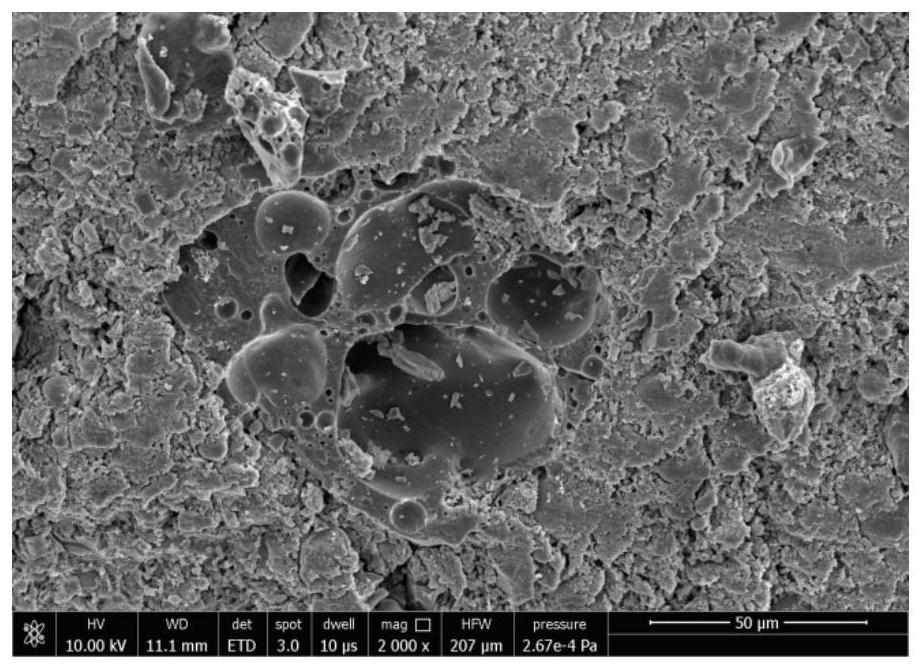

Image

Examples

preparation example 1

[0039] The cementitious material is prepared by uniformly mixing 60Kg of fly ash, 15Kg of slag micropowder and 25Kg of cement.

preparation example 2

[0041] The cementitious material is prepared by uniformly mixing 50Kg of fly ash, 15Kg of slag micropowder and 25Kg of cement.

preparation example 3

[0043] The cementitious material is prepared by uniformly mixing 70Kg of fly ash, 15Kg of slag micropowder and 25Kg of cement.

[0044] Preparation example of machine-made sand:

[0045] Preparation example 1 of machine-made sand

[0046] The particle size of machine-made sand is continuously graded in the range of 0-4.75mm, and the fineness modulus is distributed between 3.7-3.4. It is prepared by uniformly mixing 72Kg of particle size, 60Kg of particle size of 0.315-0.16mm, 32Kg of particle size of 0.16-0.075mm, and 20Kg of particle size of 0-0.075mm.

[0047] Preparation example 2 of machine-made sand

[0048] The particle size of the machine-made sand is continuously graded in the range of 0-4.75mm, and the fineness modulus is distributed between 2.5-2.8. It is prepared by uniformly mixing 108Kg of particle size, 96Kg of 0.315-0.16mm particle size, 56Kg of 0.16-0.075mm particle size, and 52Kg of 0-0.075mm particle size.

[0049] Preparation example 3 of machine-made sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com