Patents

Literature

49results about How to "The production process is convenient and fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

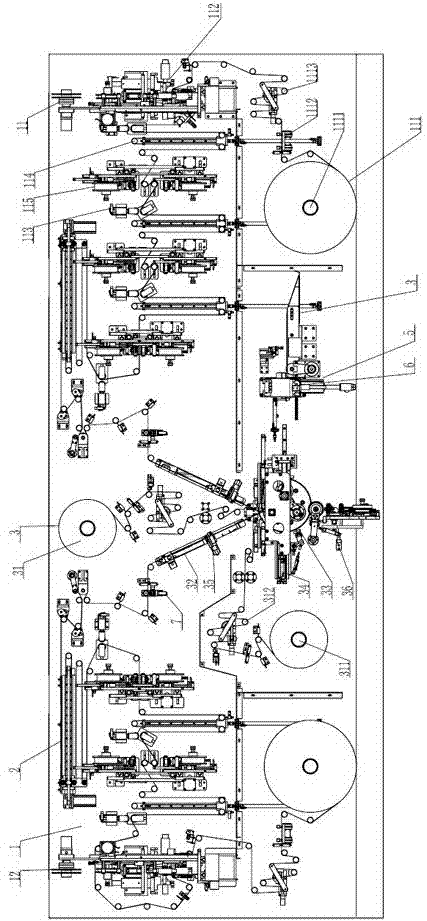

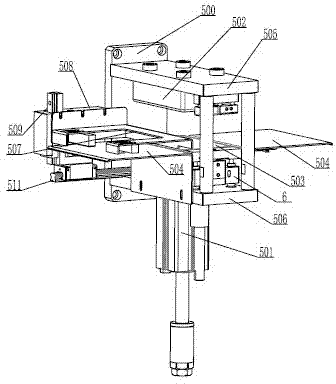

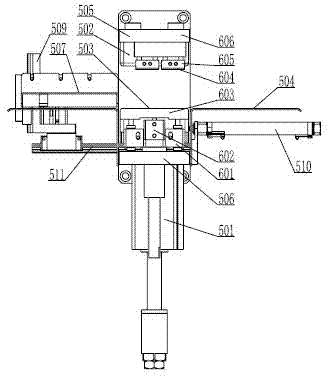

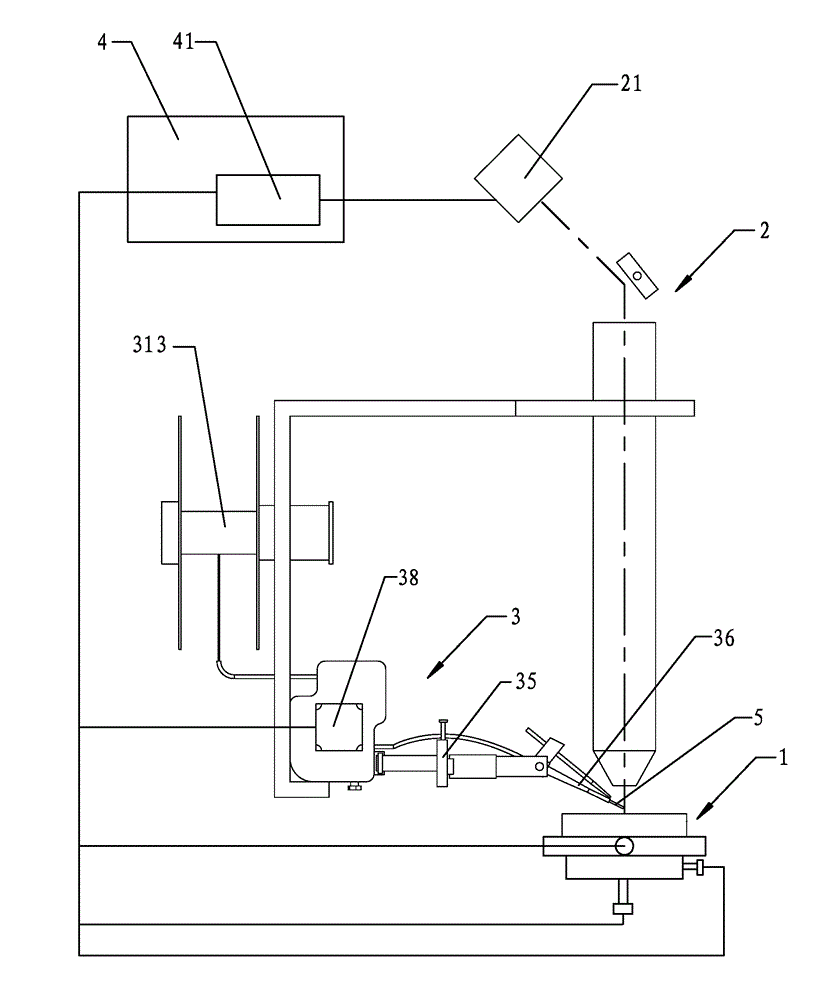

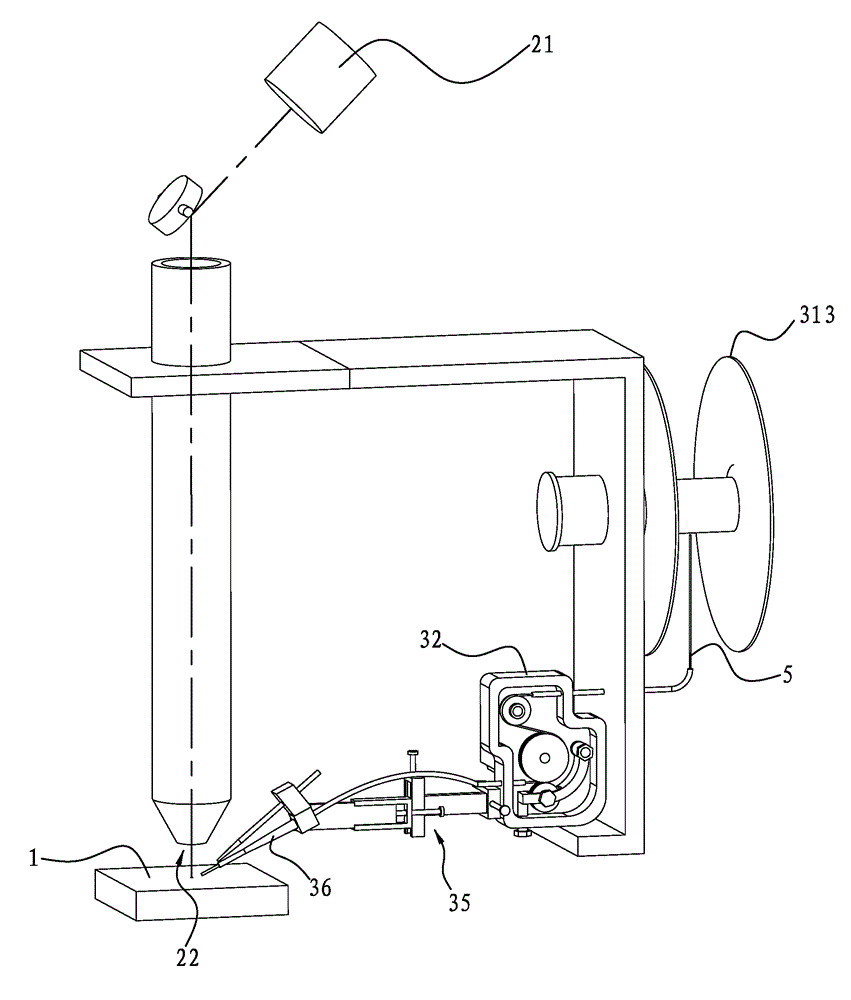

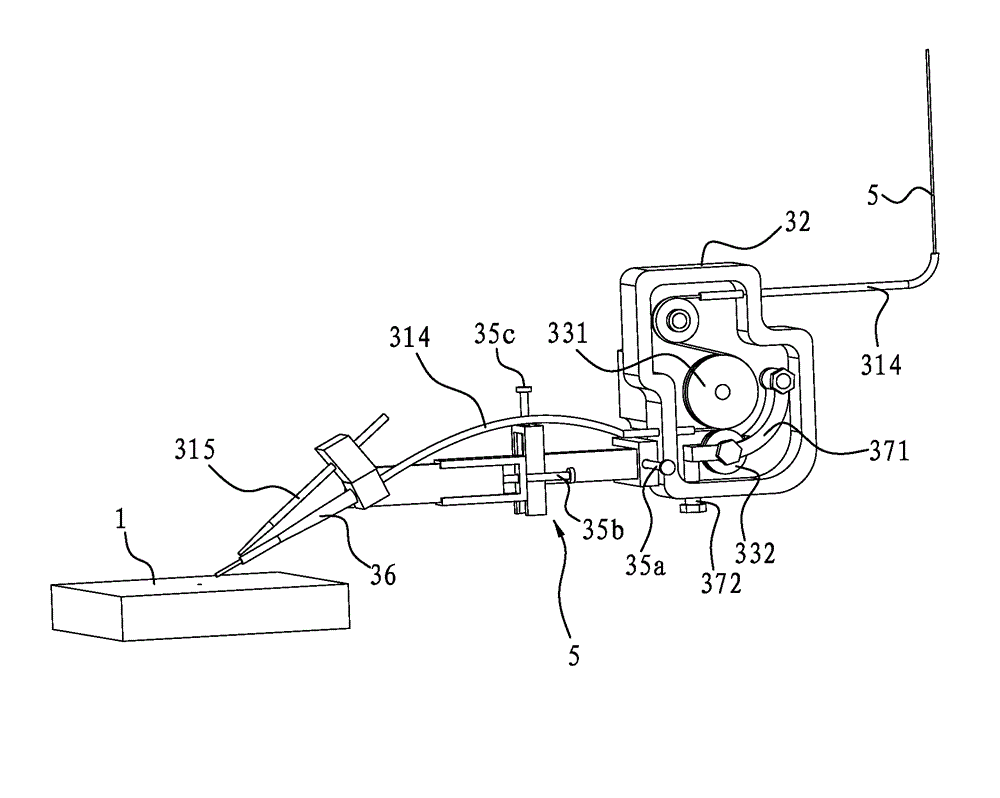

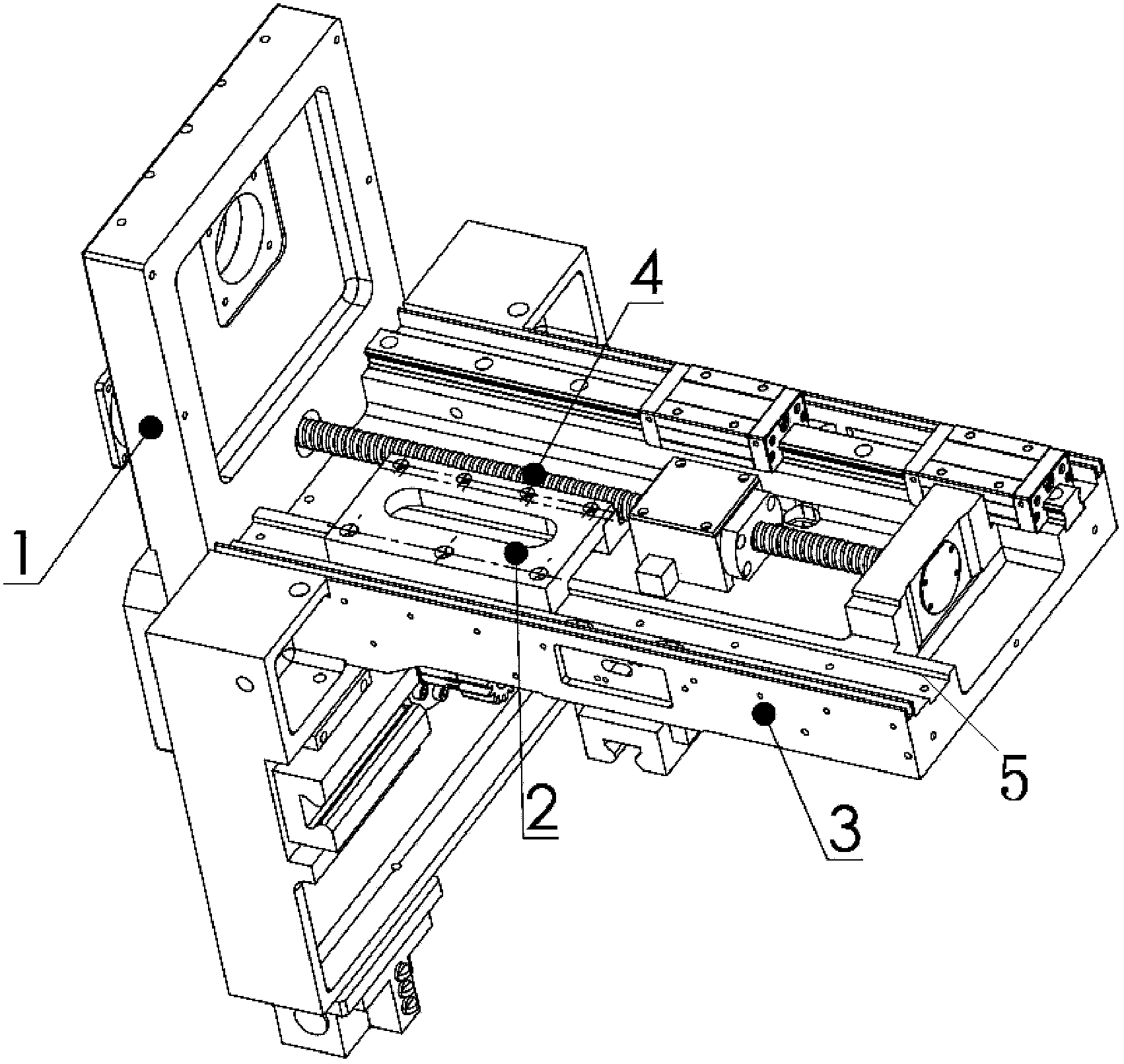

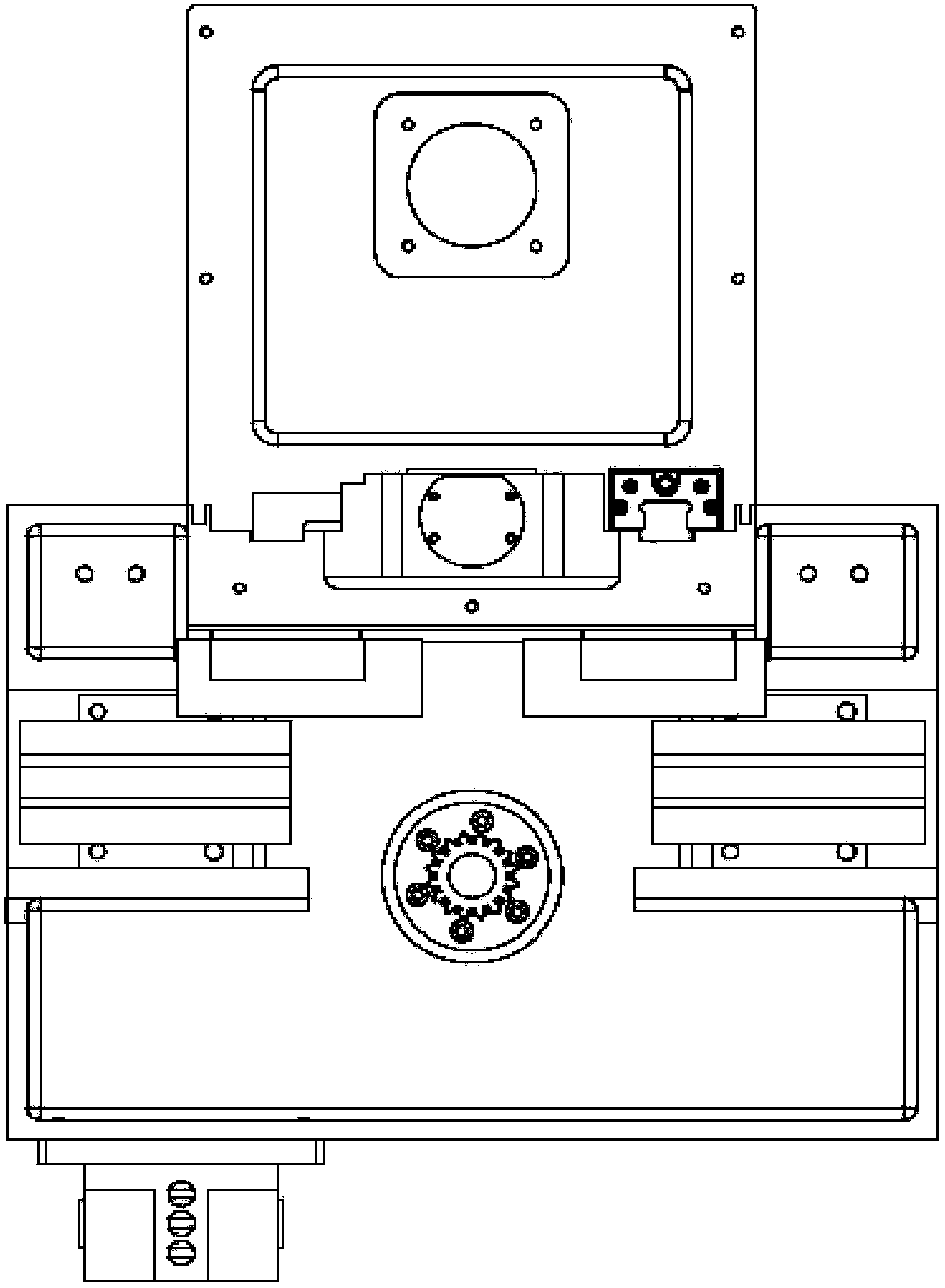

Full-automatic battery cell winding device

ActiveCN102931430AImprove consistencyReduce labor intensityFinal product manufactureSecondary cells manufactureEngineeringBattery cell

The invention discloses a full-automatic battery cell winding device. The device comprises a sheet producing portion, a winding portion and a blanking portion, wherein the sheet producing portion comprises a positive pole sheet producing unit and a negative sheet producing unit, the positive pole sheet producing unit and the negative sheet producing unit respectively comprise an unwinding mechanism, a tab welding mechanism, a traction mechanism, a tension mechanism and a rubberizing mechanism, the winding portion comprises a membrane input mechanism, a sheet inlet mechanism, a winding mechanism, a membrane cutting mechanism, a pole sheet cutting mechanism and a termination tape attaching mechanism, the full-automatic battery cell winding device also comprises a pressurization forming mechanism, and the pressurization forming mechanism is matched with the winding portion and the blanking portion and is used for pressurizing and molding a winded battery cell. The pressurization forming mechanism is arranged on the full-automatic battery cell winding device, the battery cell can be subjected to pressurization forming when the battery cell winding is completed, the production efficiency is improved, and the quality of the battery cell is improved.

Owner:SHENZHEN YINGHE TECH

High-temperature long-life self-lubricating wearproof alloy material

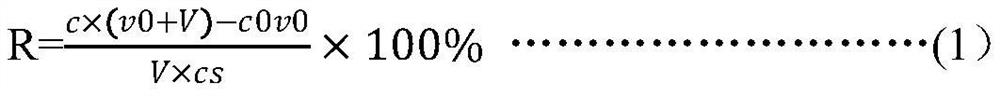

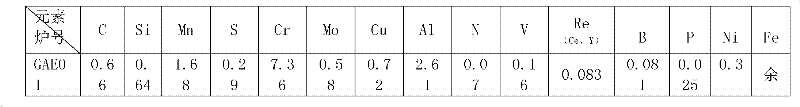

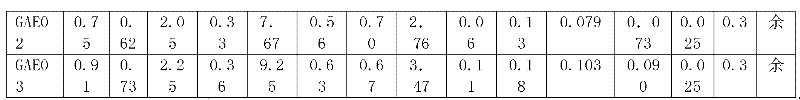

The present invention relates to the field of high temperature material, and is especially one kind of high temperature self-lubricating antiwear alloy material with long service life. The high temperature self-lubricating antiwear alloy material with long service life is the chemical composition of C 0.35-0.45 wt%, Si 0.9-1.2 wt%, Mn 6.5-8.0 wt%, Cr 15-16.5 wt%, Mo 0.35-0.45 wt%, Cu 0.8-1.2 wt%, Al 4.5-5.5 wt%, S 0.25-0.45 wt%, N 0.01-0.10 wt%, V 0.15-0.20 wt%, B 0.05-0.15 wt%, RE 0.01-0.15 wt%, P not more than 0.025 wt%, Ni not more than 0.3 wt%, and Fe for the rest. Compared with available technology, the present invention has the advantages of low cost, high heat resistance, high strength and hardness at high temperature, excellent antiwear performance and anti-friction performance, high anticorrosive performance and long service life.

Owner:BEIJING CISRI GAONA TECH

Bean dreg sauce and processing method thereof

The invention discloses bean dreg sauce. The bean dreg sauce comprises the following main materials, base sauces and seasonings in parts by weight: main materials, comprising 35-45 parts of bean dregs, 15-25 parts of edible oil, 2-4 parts of dried shrimp, 1-3 parts of dried shiitake, 4-6 parts of green onions, 4-6 parts of garlic and 3-5 parts of capsicum frutescens; base sauces, comprising 1-3 parts of bean sauce, 6-10 parts of chili sauce, 0.5-1 part of hoisin sauce and 1-2 parts of Zhuhou sauce; seasonings, comprising 0.5-1 part of oyster oil, 0.5-1 part of chicken powder, 0.2-0.6 part of monosodium glutamate and 0.1-0.5 part of salt. The bean dreg sauce is spicy and delicious.

Owner:孙怀兵

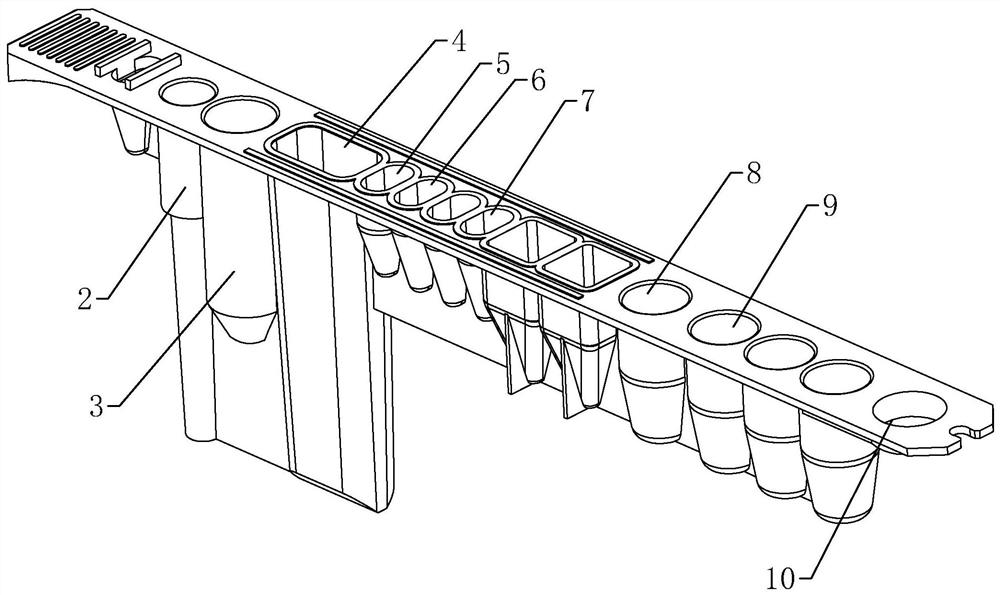

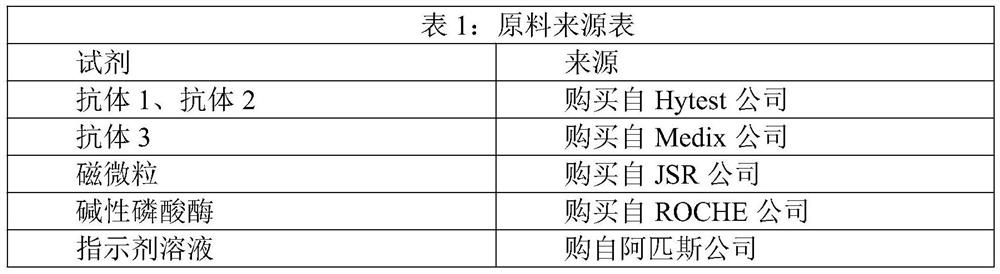

Cardiac troponin I detection reagent, preparation method and cardiac troponin I detection kit

ActiveCN111735965ASuperparamagneticIncrease the reaction areaDisease diagnosisBiological testingAntiendomysial antibodiesCardiac muscle

The invention relates to a cardiac troponin I detection reagent, a preparation method and a cardiac troponin I detection kit. The cardiac troponin I detection reagent comprises a coated antibody solution, a detection antibody solution and an indicator solution, wherein the coated antibody comprises an antibody and stationary phase conjugate 1 obtained by coupling an antibody 1 with a stationary phase, and an antibody and stationary phase conjugate 2 obtained by coupling an antibody 2 with a stationary phase; the detection antibody is obtained by coupling an antibody 3 with a marker; and the indicator solution contains an indicator for quantitatively detecting the concentration of the marker. The invention also comprises the preparation method of the detection reagent and a kit using the detection reagent. In the invention, the antibody 2 and the antibody 3 can be respectively combined with the cardiac troponin I, so that the sufficient separation of the cardiac troponin I is facilitated, and the detection sensitivity of the reagent to the cardiac troponin I is further improved.

Owner:SOPHONIX CO LTD

Material-saving heat-resisting antifriction self-lubricating material

The invention discloses a material-saving heat-resisting antifriction self-lubricating material, belonging to the technical field of metal self-lubricating friction materials, and is especially suitable for preparing parts serving under a temperature of 300-1050 DEG C. The material comprises the following ingredients: 0.75-0.95 wt% of C, 0.6-0.8 wt% of Si, 1.5-2.5 wt% of Mn, 6.5-9.5 wt% of Cr, 0.55-0.65 wt% of Mo, 0.65-0.75 wt% of Cu, 2.5-3.5 wt% of Al, 0.25-0.45 wt% of S, 0.05-0.10 wt% of N, 0.05-0.10 wt% of B, 0.10-0.20 wt% of V, 0.05-0.15 wt% of RE, no larger than 0.015 wt% of P, no largerthan 0.3 wt% of Ni, and the balance consisting of Fe, wherein, RE comprises Ce, Y and the like. Compared with materials in the prior art, the self-lubricating material disclosed herein has the advantages of low cost, wide heat-resisting region, high high-temperature hardness, high thermal fatigue resistance, high antifriction quality and high wear resistance, high temperature oxidation resistance, industrial wet and hot corrosion resistance, low tendency of cracking and chipping in use, small erosion of abrasive materials, and long service life.

Owner:CENT IRON & STEEL RES INST

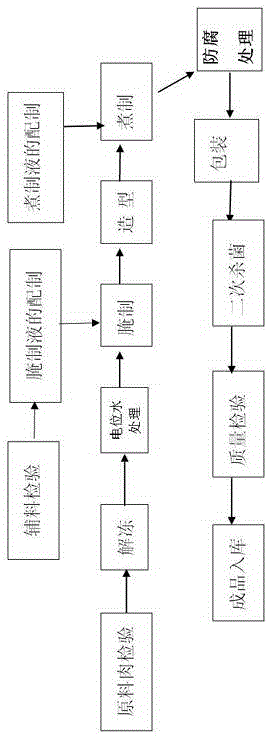

Vacuum-packed roast chicken making method

The invention provides a vacuum-packed roast chicken making method. Spent hens with the age smaller than 1 year are selected to be pretreated, slaughtering, blood purifying, feather removal, giblet removal, cleaning and low-temperature acid discharge are conducted on the spent hens, and the treated hens are frozen for use. The roast chicken process includes the steps of unfreezing, cleaning, electrolyzed-oxidizing water soaking, sousing, modelling, cooking, sugar smoking, cooking, preservative treatment, packaging, secondary heat sterilization and finished product forming. By means of the vacuum-packed roast chicken making method, the ingredients are simple, the making process is convenient and fast to conduct, the cost is low, the taste is good, the production process is stable, no food ingredients and chemical preservative harmful to the human body health are added, the flavor is unique, the chewiness is achieved, and the roast chicken can be eaten by consumers of all ages.

Owner:唐山市施尔得肉制品有限公司

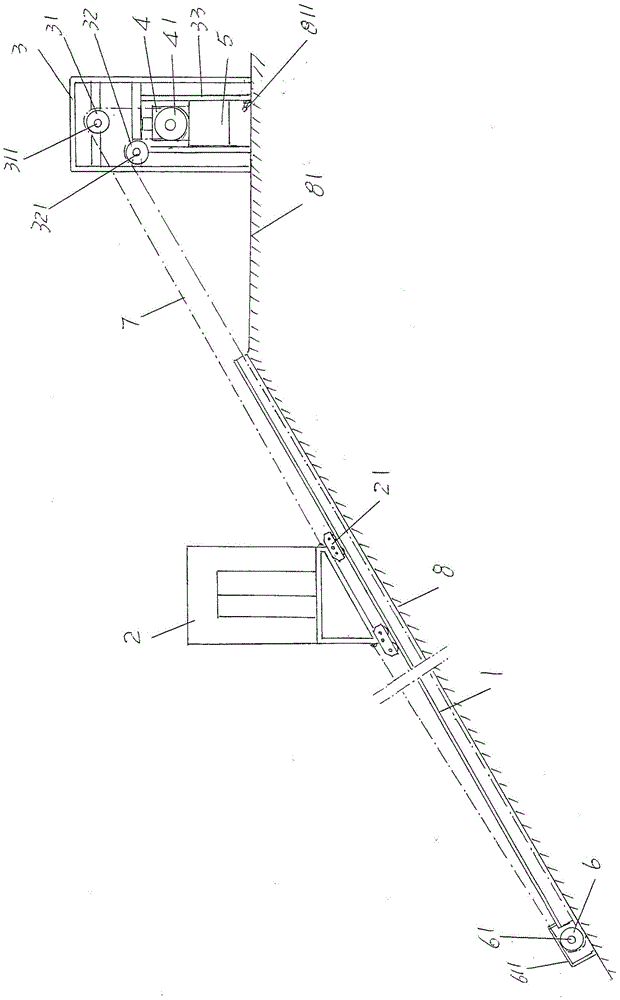

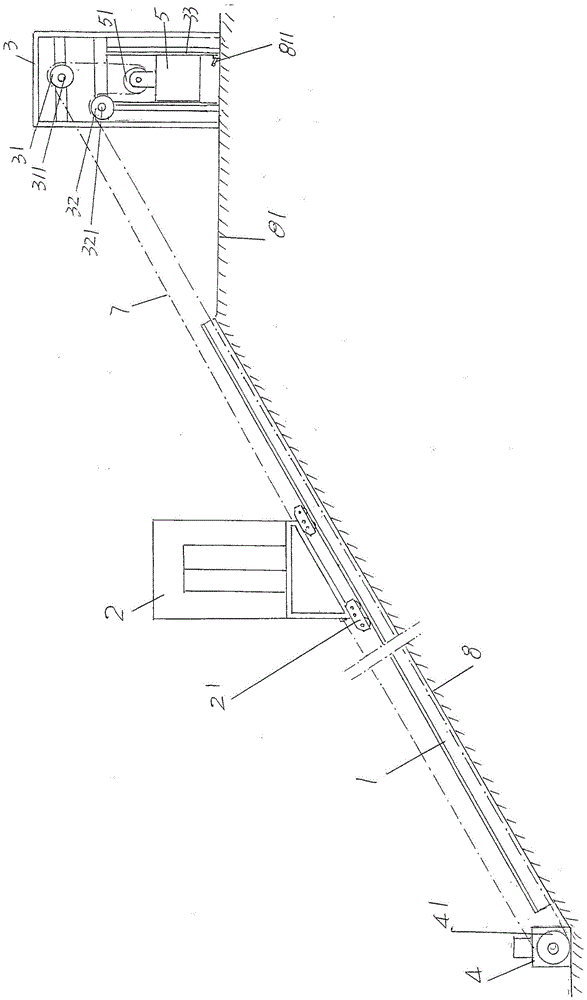

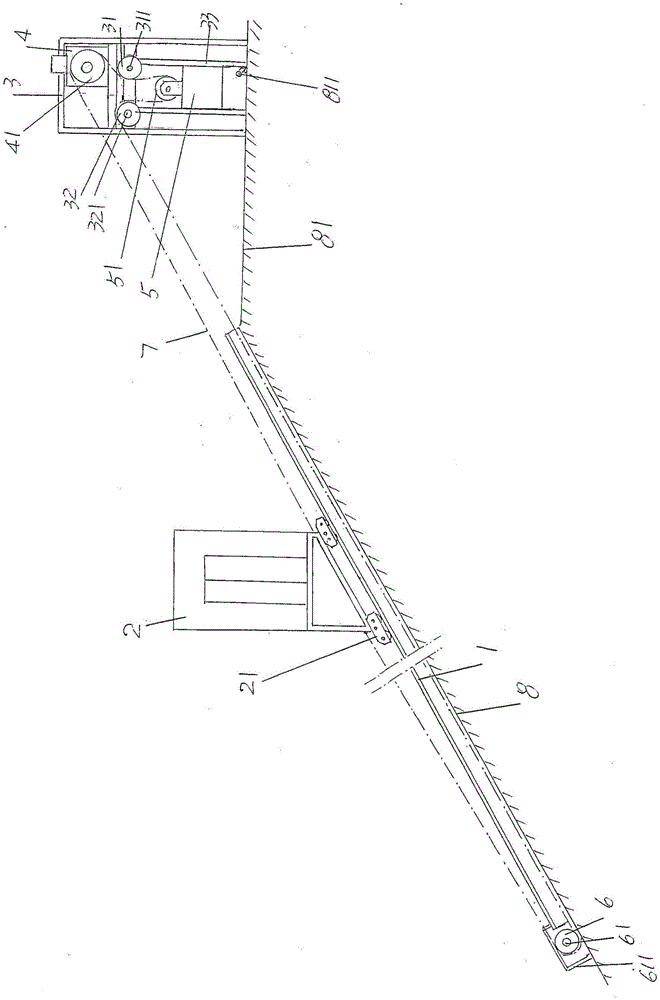

Counter-weight-free traction type inclined elevator

InactiveCN105600648ASave resourcesSimple structureElevatorsBuilding liftsAgricultural engineeringPulley

The invention discloses a counter-weight-free traction type inclined elevator, and belongs to the technical field of elevators. The counter-weight-free traction type inclined elevator comprises a pair of guide rails, an elevator cage, a stander, a traction machine, a tensioning weight and a rope returning wheel, wherein the guide rails are laid along the slope of a guide rail carrier; the elevator cage and the pair of guide rails form a rolling pair through the guide boots at the bottom of the elevator cage; the stander is arranged on a platform at the top of the slope, and upper and lower pulleys are arranged on the stander; when the traction machine is arranged on the stander, the tensioning weight is connected to the lower part of the traction machine or is wound by a cage traction rope under a state that the traction machine is separated; the rope returning wheel is arranged at the bottom of the slope; when the traction machine is arranged at the bottom of the slope, the rope returning wheel is removed, and a traction wheel is used as the rope returning wheel; both ends of the cage traction rope are connected with the lower part of the elevator cage, and the middle part of the cage traction rope is wound to the upper pulley, the traction wheel, the lower pulley and the rope returning wheel in sequence or wound to the upper pulley, the tensioning weight, the lower pulley and the traction wheel in sequence or wound to the traction wheel, the upper pulley, the tensioning weight, the lower pulley and the rope returning wheel in sequence. According to the counter-weight-free traction type inclined elevator, resources are saved, and the structure is simplified; the counter-weight-free traction type inclined elevator is convenient and quick to manufacture and mount, and the cost is reduced.

Owner:SUZHOU LAIYIN ELEVATOR CO LTD

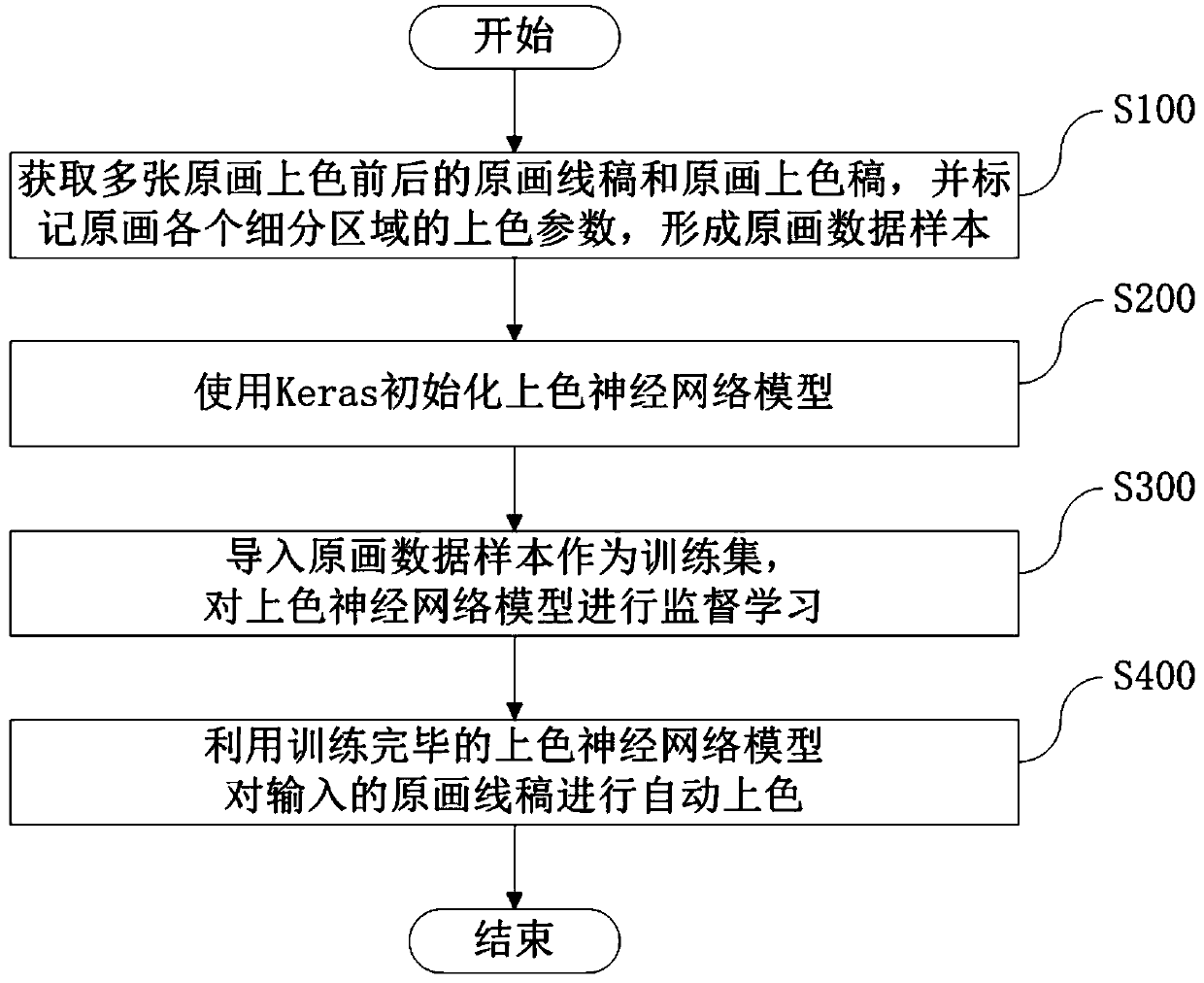

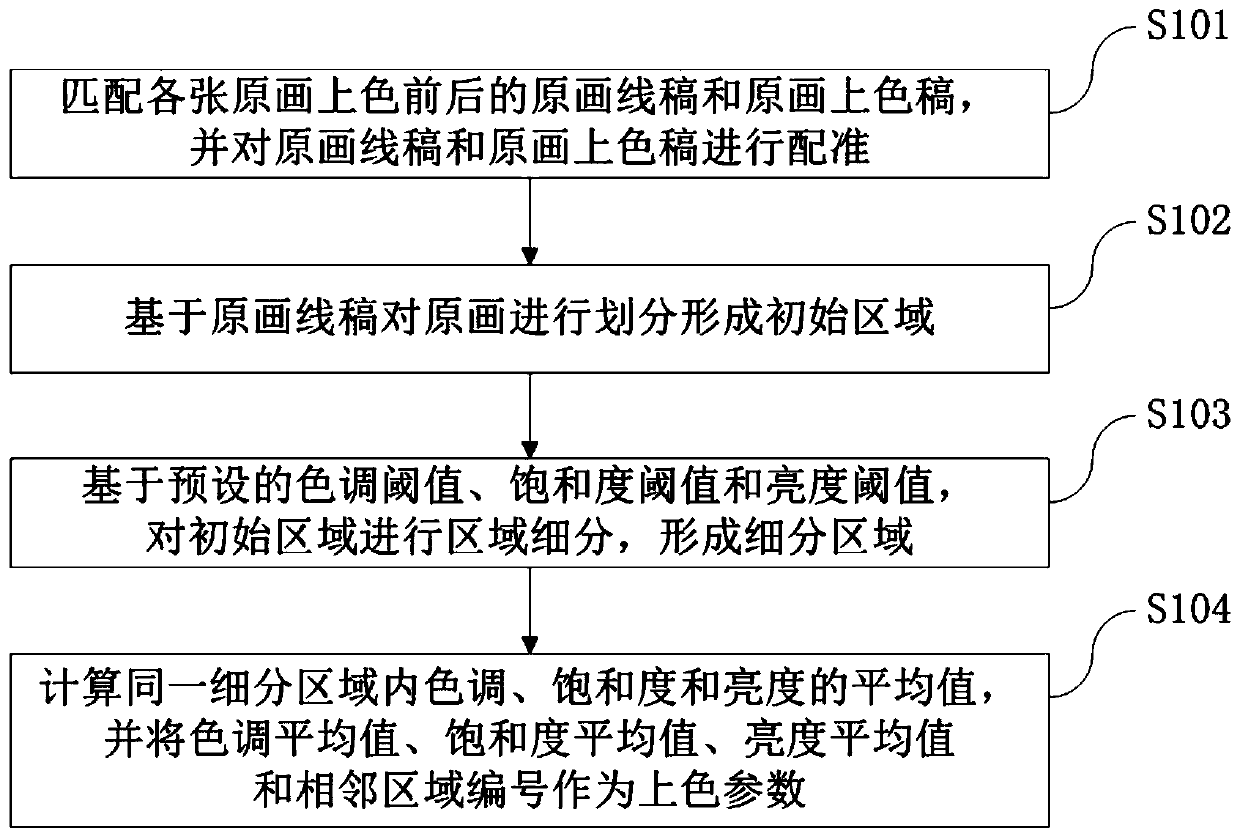

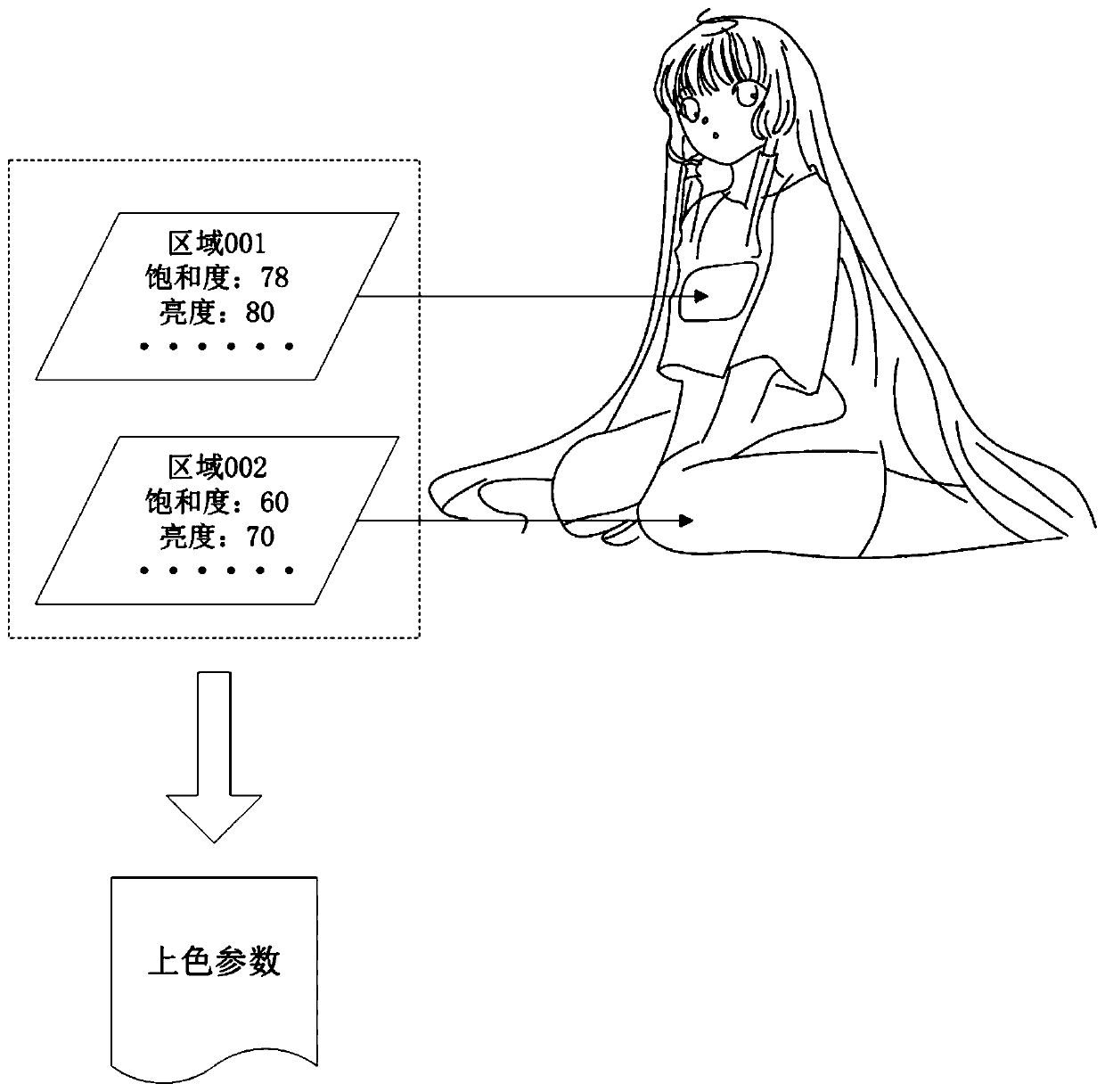

Original picture auxiliary coloring method and device based on a neural network

ActiveCN109801346ALighten heavy coloring workThe production process is convenient and fastCharacter and pattern recognitionNeural architecturesAlgorithmNetwork model

An original picture auxiliary coloring method based on a neural network comprises the steps of acquiring original line drawing manuscripts and original picture coloring manuscripts before and after coloring of a plurality of original pictures, marking coloring parameters of all subdivided areas of the original pictures, and forming original picture data samples; Using Keras to initialize a coloring neural network model, wherein the coloring neural network model adopts a VGG model; Importing an original picture data sample as a training set, and carrying out supervised learning on the coloringneural network model; and automatically coloring the input original line drawing by using the trained coloring neural network model. The invention further discloses a corresponding original picture auxiliary coloring device based on the neural network. The method has the beneficial effects that auxiliary coloring is carried out on the original picture by utilizing the neural network, so that heavycoloring work in the coloring process of the original picture is reduced, and the original picture can be conveniently and quickly manufactured and modified.

Owner:武汉金山世游艺创文化有限公司

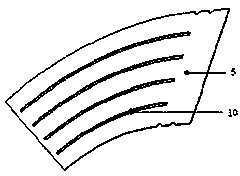

Physical-gain black rear projection hard screen and manufacturing method thereof

The invention provides a physical-gain black rear projection hard screen which is low in price, unlimited in screen area size, resistant to ambient light, very solid in black bit, clear in screen effect and high in contrast. The physical-gain black rear projection hard screen can overcome defects in the prior art, and is easy and convenient to produce and use and low in cost; according to own needs for different screen area sizes, requirements on the screen display effect can be met; a clear picture, a high viewing angle, accurate color reproduction, and a good watching effect at different distances can be fully met.

Owner:张雅婧 +1

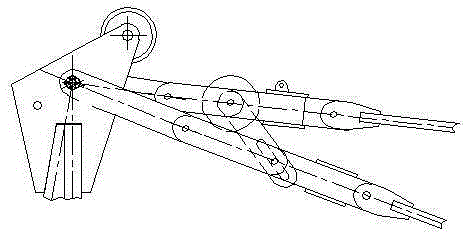

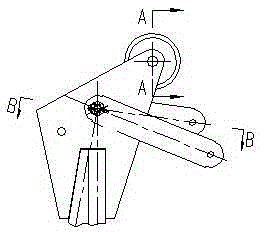

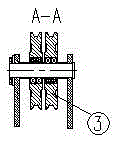

Tower crane cargo boom pull rod structure

The invention discloses a tower crane cargo boom pull rod structure. The tower crane cargo boom pull rod structure comprises a single tower top pulley (3), an inner pull plate (1), an outer pull plate (2), an inner pull rod (5) and an outer pull rod (6), and further comprises an inner adjusting plate (7) and an outer adjusting plate (8), wherein the two ends of the inner adjusting plate (7) are connected with the inner pull plate (1) and the inner pull rod (5) respectively, and the two ends of the outer adjusting plate (8) are connected with the outer pull plate (2) and the outer pull rod (6) respectively. The tower crane cargo boom pull rod structure has the beneficial effects that a plate pulling device structure is omitted, the number of tower top pulley sets is decreased, cargo boom pull rod manufacturing becomes simple, and cost is reduced; and a pull rod is easily installed in place by additionally arranging the inner adjusting plate and the outer adjusting plate.

Owner:XUZHOU CONSTR MACHINERY

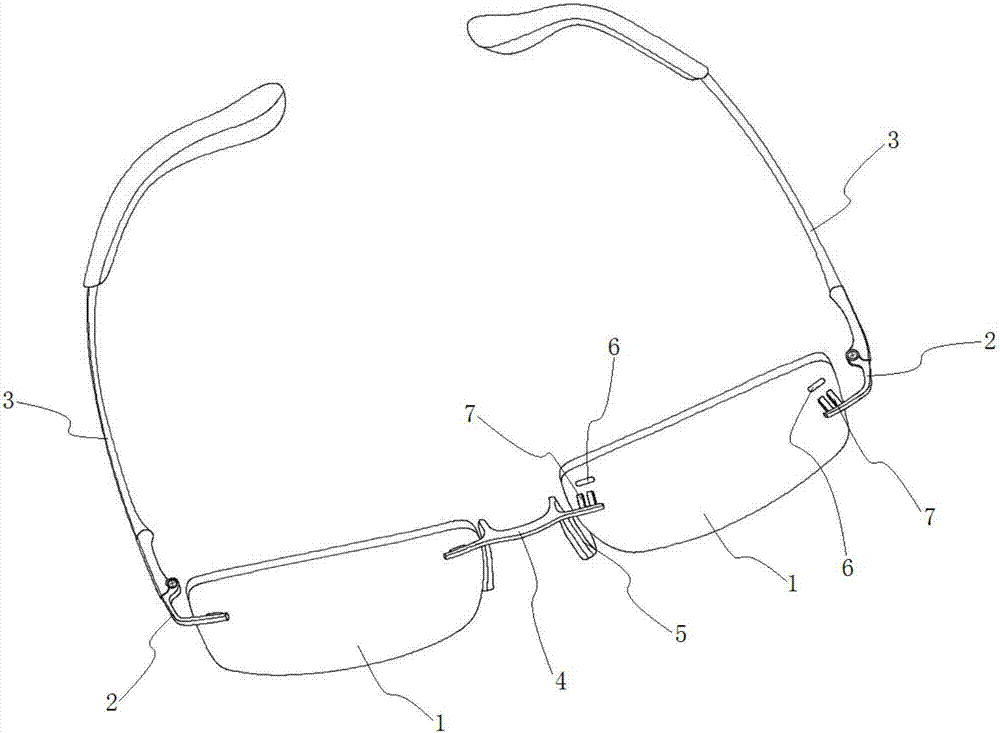

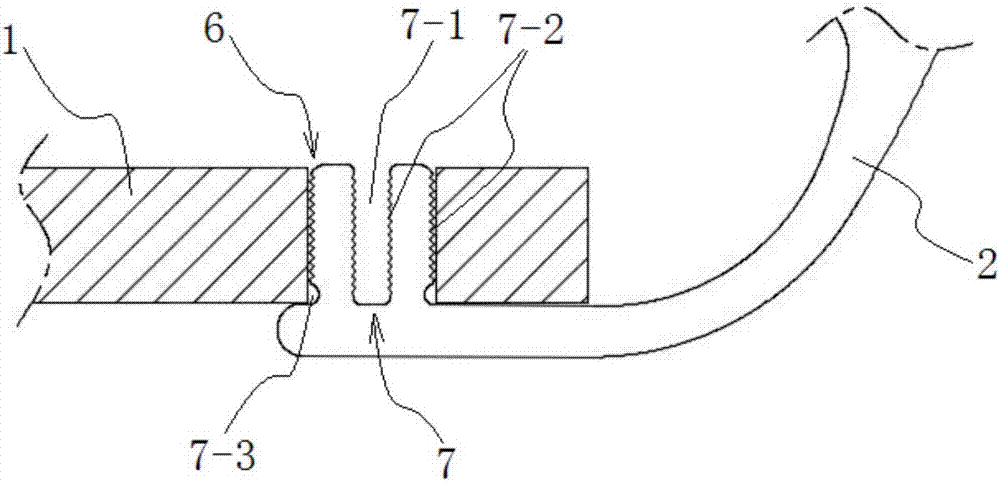

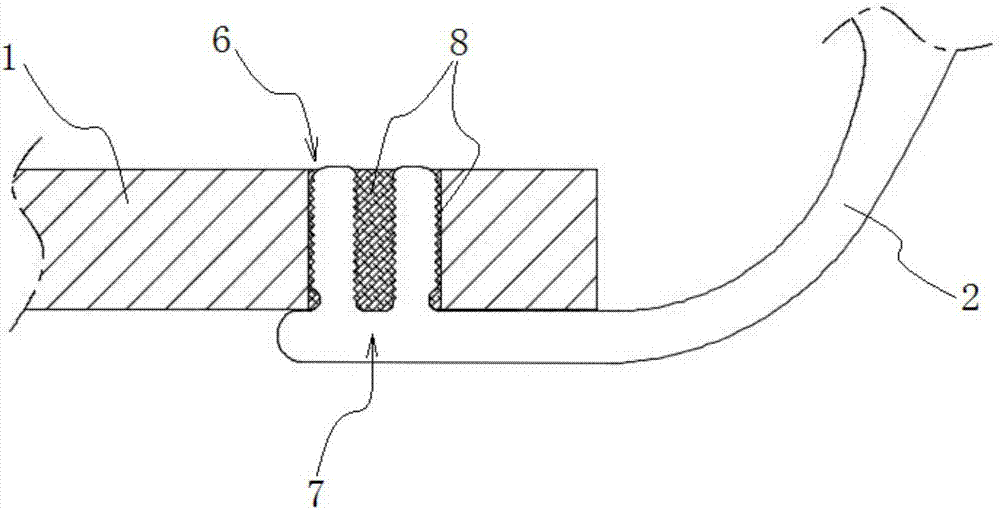

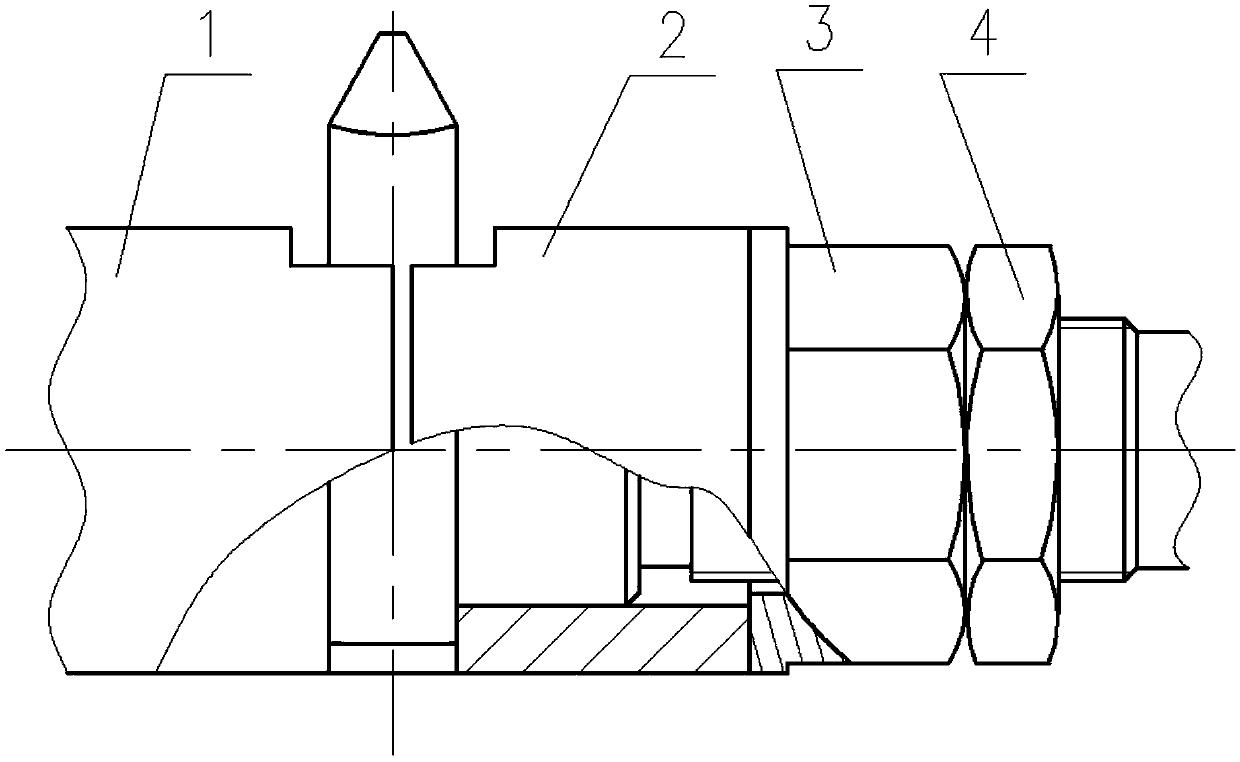

Lens connecting structure of rimless eyeglasses and rimless eyeglasses using lens connecting structure

PendingCN107065216AIncreased frictionSecure connectionSpectales/gogglesLens assembliesEngineeringNose bridge

The invention discloses a lens connecting structure of rimless eyeglasses and rimless eyeglasses using the lens connecting structure, which belong to the field of the eyeglasses structure. The lens connecting structure disclosed by the invention comprises connecting holes formed in lenses and insertion tabs which are arranged on pile tips or a nose bridge and can be tightly inserted in the connecting holes in a matched manner to stop rotation, wherein an opening is formed in the middle part of each insertion tab along an insertion tab inserting direction, teeth are at least arranged on external sidewalls of the two sides of each insertion tab, and glue or fastening plugs are further arranged in the openings of the insertion tabs. The invention further discloses the rimless eyeglasses. According to the lens connecting structure of the rimless eyeglasses and the rimless eyeglasses using the lens connecting structure, the insertion tabs on the pile tips or the nose bridge of the eyeglasses are in close fit with the connecting holes in the lenses, the friction action between the insertion tabs and the connecting holes is improved by using the teeth on the external sidewalls of the two sides of each insertion tab, and a locking fixing force between the insertion tabs and the connecting holes is increased by arranging the glue or fastening plugs are in the openings of the middle parts of the insertion tabs, so that the lenses of the rimless eyeglasses are firm and reliable in connection and are not prone to loosening; the lens connecting structure has the advantages of simple structure, convenience and quickness in manufacturing and assembling, and the like, so that the manufacturing cost of the rimless eyeglasses is effectively reduced.

Owner:马锋

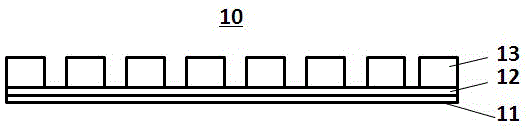

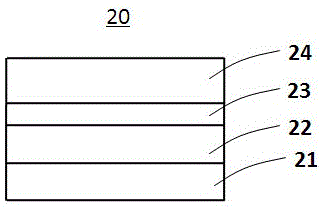

Etching mask and method for manufacturing LED by aid of same

ActiveCN106784196AThe production process is convenient and fastReduce manufacturing costOriginals for photomechanical treatmentSemiconductor devicesDry etchingSemiconductor

The invention belongs to the field of processes for manufacturing semiconductors, and relates to an etching mask and a method for manufacturing an LED by the aid of the same. The etching mask comprises a first flexible substrate, a first adhesion layer and a patterned structural layer. The first flexible substrate, the first adhesion layer and the patterned structural layer are sequentially lapped on one another and are closely adhered with one another. The method includes arranging the etching mask on the surface of an epitaxial wafer; transferring patterns of the patterned structural layer onto the epitaxial wafer by means of dry etching; manufacturing a patterned epitaxial wafer. The etching mask and the method have the advantages that the etching mash and the method are convenient and speedy, and the cost can be saved; a second adhesion layer and a second flexible substrate can be adhered on the patterned structural layer after the patterned structural layer is subjected to dry etching, the patterned structural layer can be peeled off to form an etching mask again, and accordingly the etching mask can be recycled.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

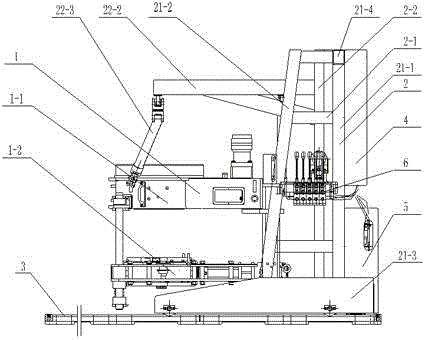

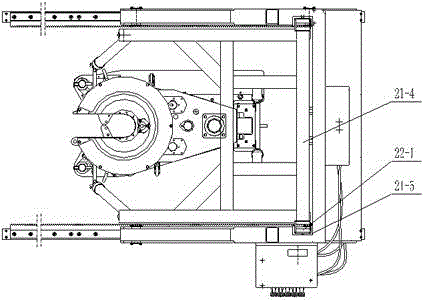

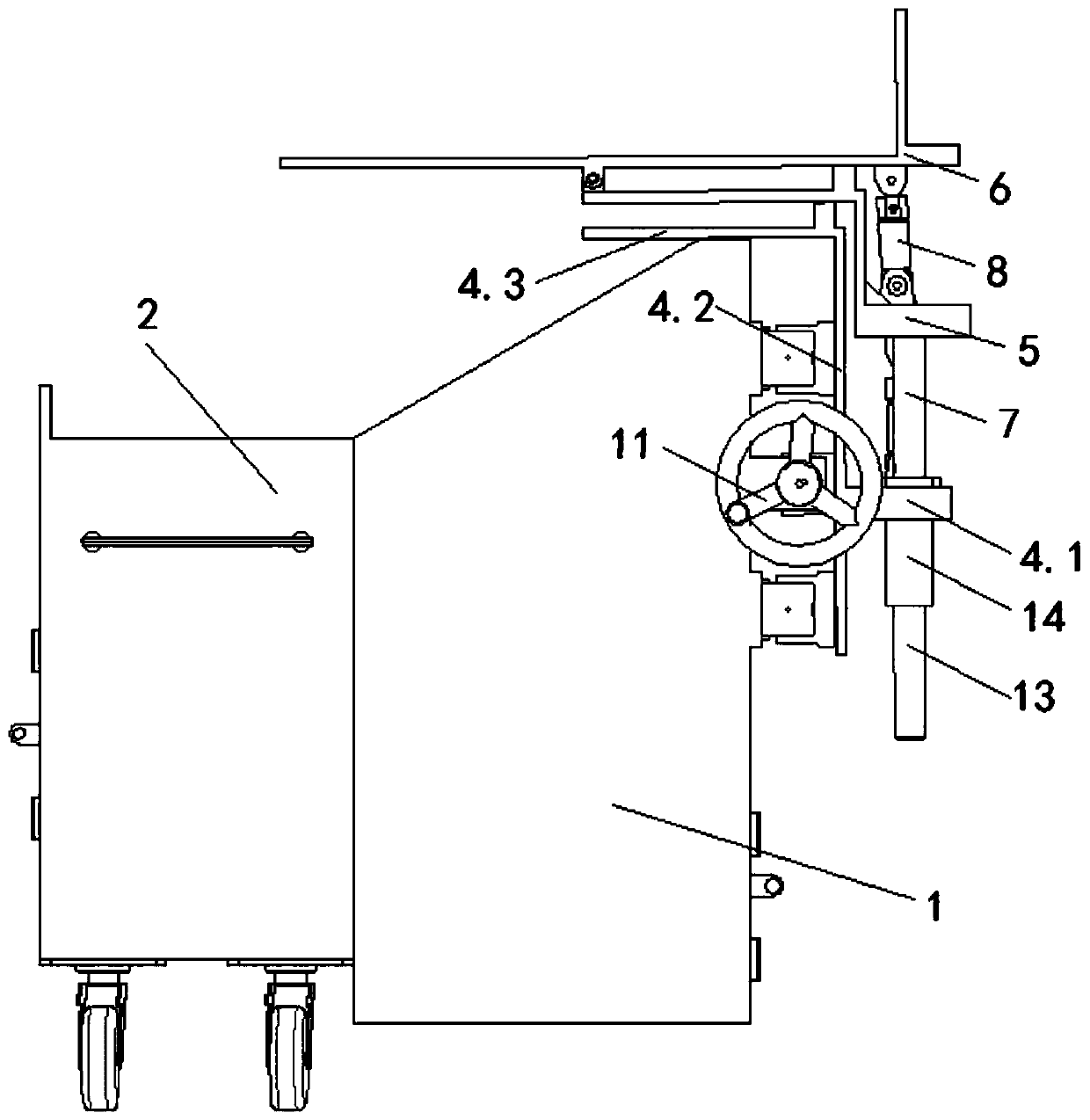

Height-adjustable automatic reciprocating traveling power tongs device

InactiveCN104533319AImprove securityImprove bearing strengthDrilling rodsDrilling casingsRemote controlEngineering

The invention discloses a height-adjustable automatic reciprocating traveling power tongs device. The device comprises hydraulic power tongs which comprise a main tong and a back tong. The hydraulic power tongs are hung on a traveling support, and a traveling rail is laid at the bottom of the traveling support. The traveling support comprises an outer frame portion and an inner frame portion. The inner frame portion is connected with an outer frame portion through a hydraulic lifting unit and is capable of rising and descending along the inside of the outer frame portion. By means of the device, the device is moved front and back through the traveling support, the power tongs can rise and descend freely relative to a drilling table surface and can pass through the wellhead to a mouse hole opening, a cylinder and a suspension unit are not needed to be moved, the whole operation process can be completed through one person and can be completed through remote control, and accordingly, the labor intensity is reduced greatly, and the worker safety factor is improved.

Owner:刘承建

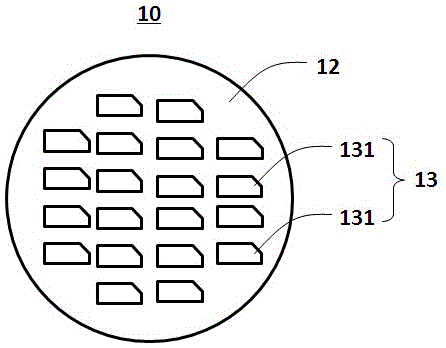

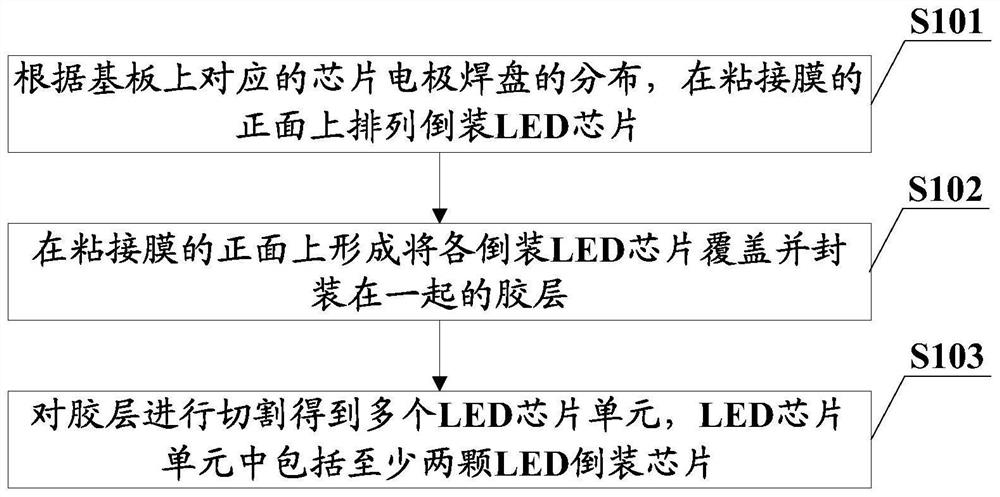

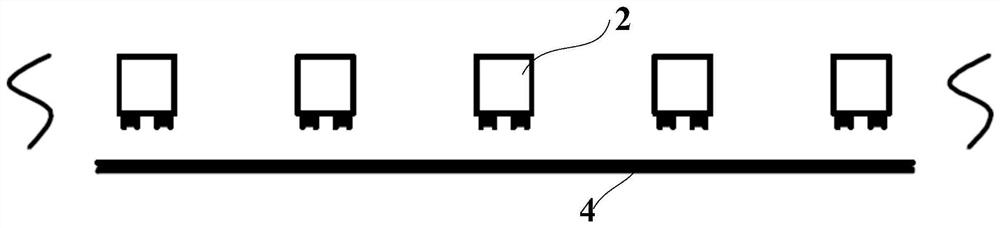

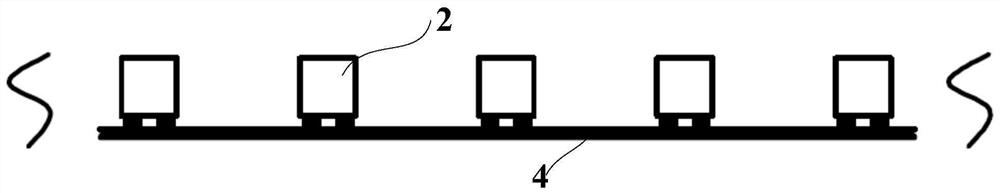

LED chip unit and LED device, and manufacturing methods thereof

PendingCN113054072AImprove Die Bonding EfficiencyQuality improvementSemiconductor devicesEngineeringSolder paste

The invention provides an LED chip unit and an LED device, and manufacturing methods thereof. Flip LED chips are arranged on the front surface of an adhesive film according to the distribution of corresponding chip electrode bonding pads on a substrate, and an adhesive layer which covers and packages the flip LED chips together is formed on the front surface of the adhesive film; and the adhesive layer is cut to obtain a plurality of LED chip units, each LED chip unit comprises at least two LED flip chips, and the LED flip chips are correspondingly distributed according to the distribution of corresponding chip electrode bonding pads on the substrate. When the LED chip unit is used for manufacturing the LED device, the LED chip unit comprising a plurality of LED chips can be transferred to the substrate, and the positive electrode and the negative electrode of each LED chip in the LED chip unit are electrically connected with the corresponding chip electrode bonding pads on the substrate respectively, so the die bonding efficiency of the LED chip can be multiplied, and the viscisity and the conductivity of elargol and solder paste printed on the bonding pad of the substrate are prevented from becoming poor due to long die bonding time, and the quality and the reliability of an LED device product are improved.

Owner:SHENZHEN JUFEI OPTOELECTRONICS

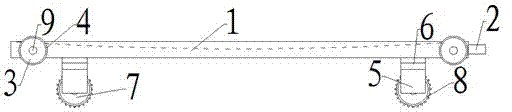

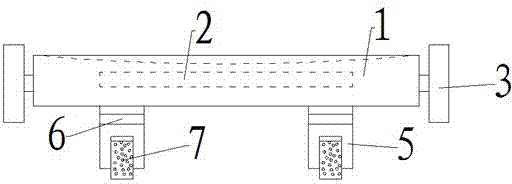

Automatic falling material receiving mechanism used for laser pipe cutting machine

InactiveCN109822241AGuaranteed not to bend in the axial directionHigh precisionLaser beam welding apparatusWaste collectionEngineering

Owner:武汉华俄激光工程有限公司

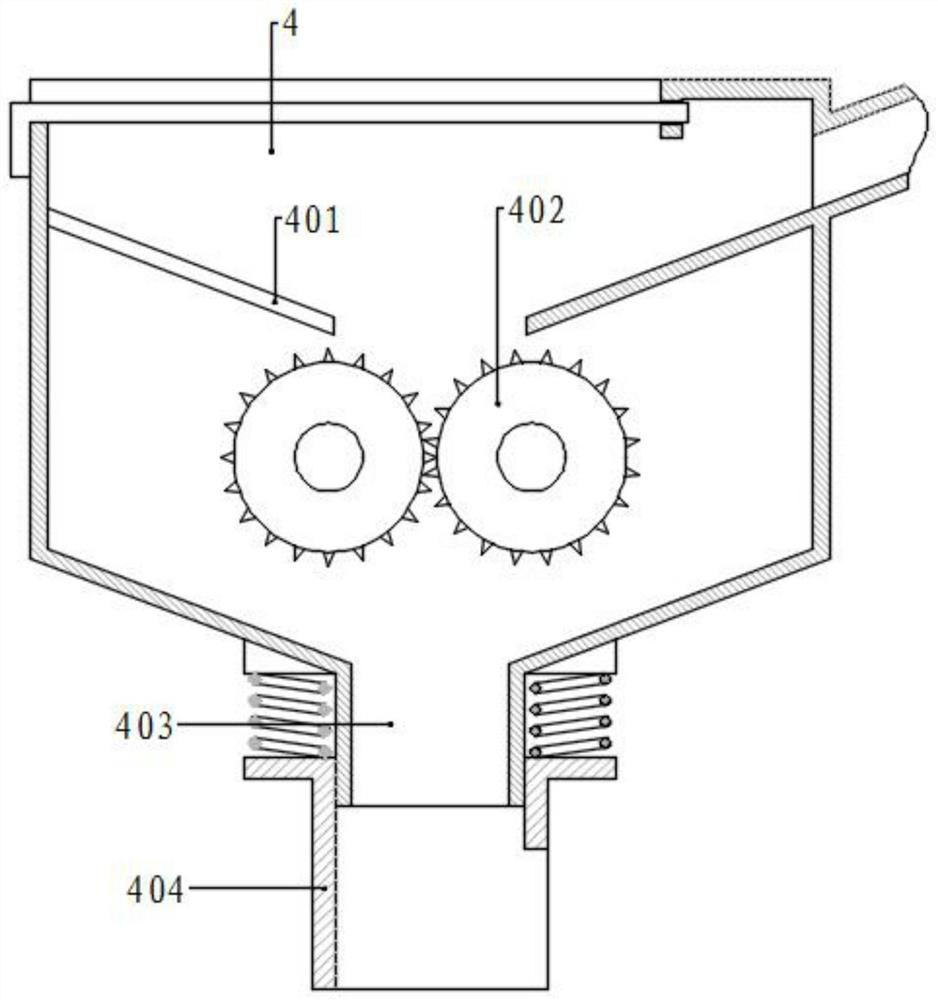

Concrete preparation device and use method thereof

PendingCN114770752ASmall particle sizeTimely recyclingMixing operation control apparatusPretreatment controlMaterials preparationStructural engineering

The invention discloses a concrete preparation device in the technical field of concrete preparation, the concrete preparation device comprises a base, a conveying belt, a first crushing assembly, a second crushing assembly and a screening box, a screening assembly and a material pushing assembly are arranged in the screening box, inclined discharging grooves are formed in the two sides of the interior of the screening box, and the outer side ends of the two discharging grooves are jointly connected with a material collecting pipe; materials are conveyed into the first smashing assembly to be smashed for the first time and then enter the screening box, the materials are screened through the screening assembly, and the materials which do not pass through screening are pushed to the two sides of the screening assembly through the pushing assembly and fall into the discharging groove, so that the situation that too much materials are accumulated on the screening assembly, and follow-up screening is affected is avoided; and the materials enter the second crushing assembly to be subjected to secondary crushing, the particle size of the materials is reduced, the materials which do not pass through screening can be recycled in time, the material transferring operation is reduced, and material preparation and treatment are faster and more convenient.

Owner:南通城宇材料科技有限公司

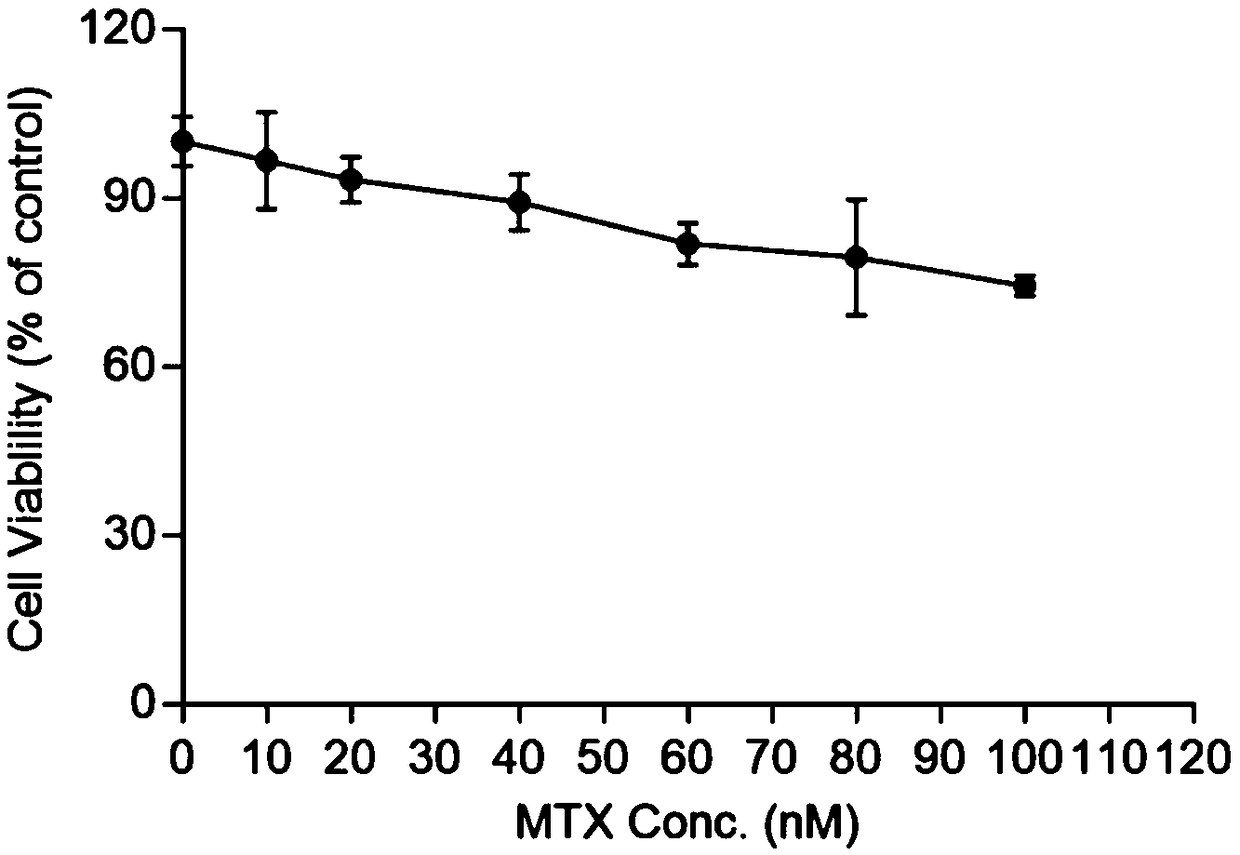

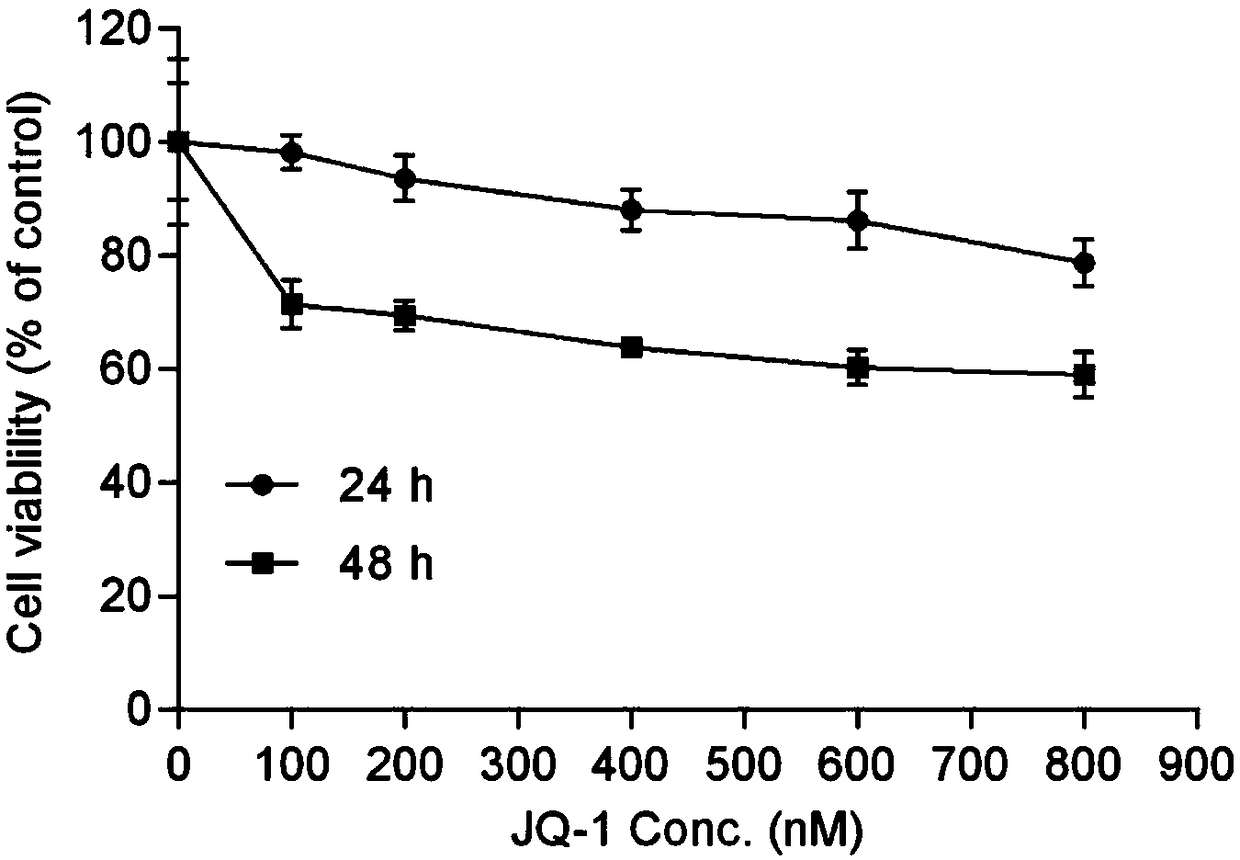

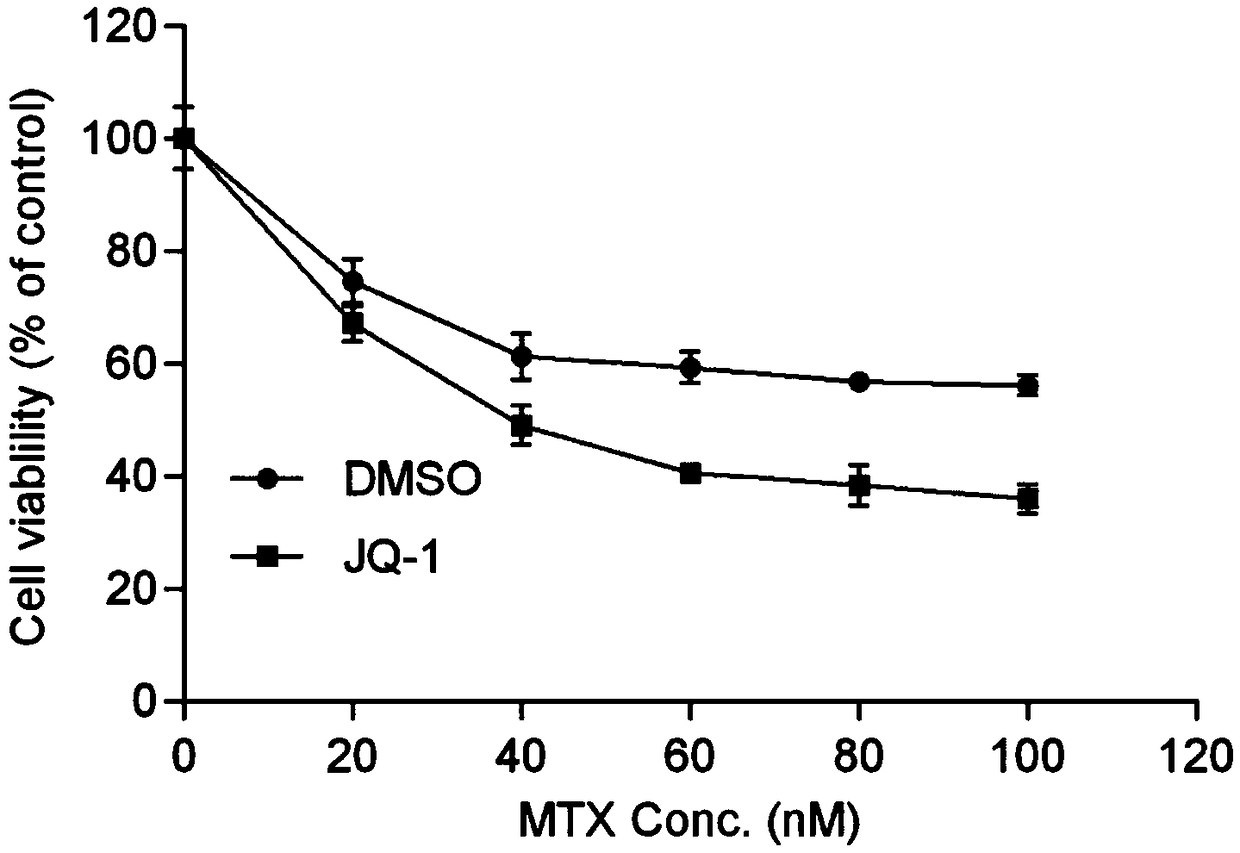

Pharmaceutical composition for treating cancer and application of pharmaceutical composition

InactiveCN108743591AGrowth inhibitionPrevent proliferationOrganic active ingredientsAntineoplastic agentsBULK ACTIVE INGREDIENTActive ingredient

The invention relates to a pharmaceutical composition for treating the cancer and an application of the pharmaceutical composition. The pharmaceutical composition comprises methotrexate as an active ingredient and a BRD4 protein inhibitor, and the mass ratio of the methotrexate to the BRD4 protein inhibitor ranges from 10:1 to 1:8. The pharmaceutical composition obviously improves the chemotherapeutic effect of the methotrexate, the similar chemotherapeutic effect is achieved by using the methotrexate at the relatively low concentration, therefore, the toxicity on a nude mouth is obviously reduced, and the injury of the pharmaceutical composition on the organism is reduced, so that the pharmaceutical composition is applied to preparation of anti-tumor drugs.

Owner:SUZHOU UNIV

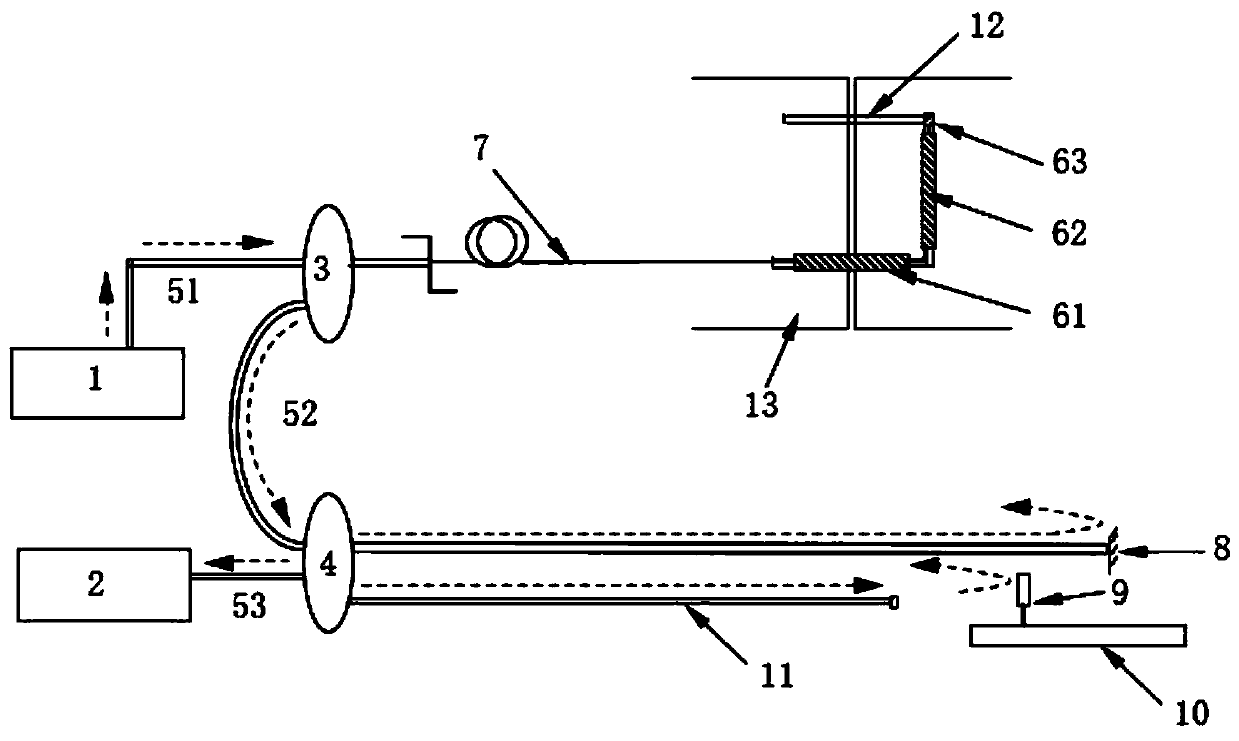

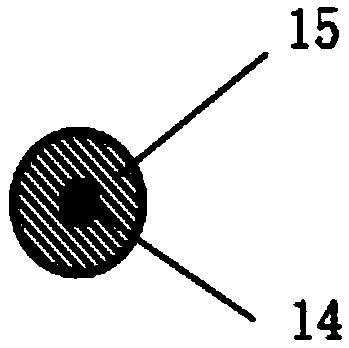

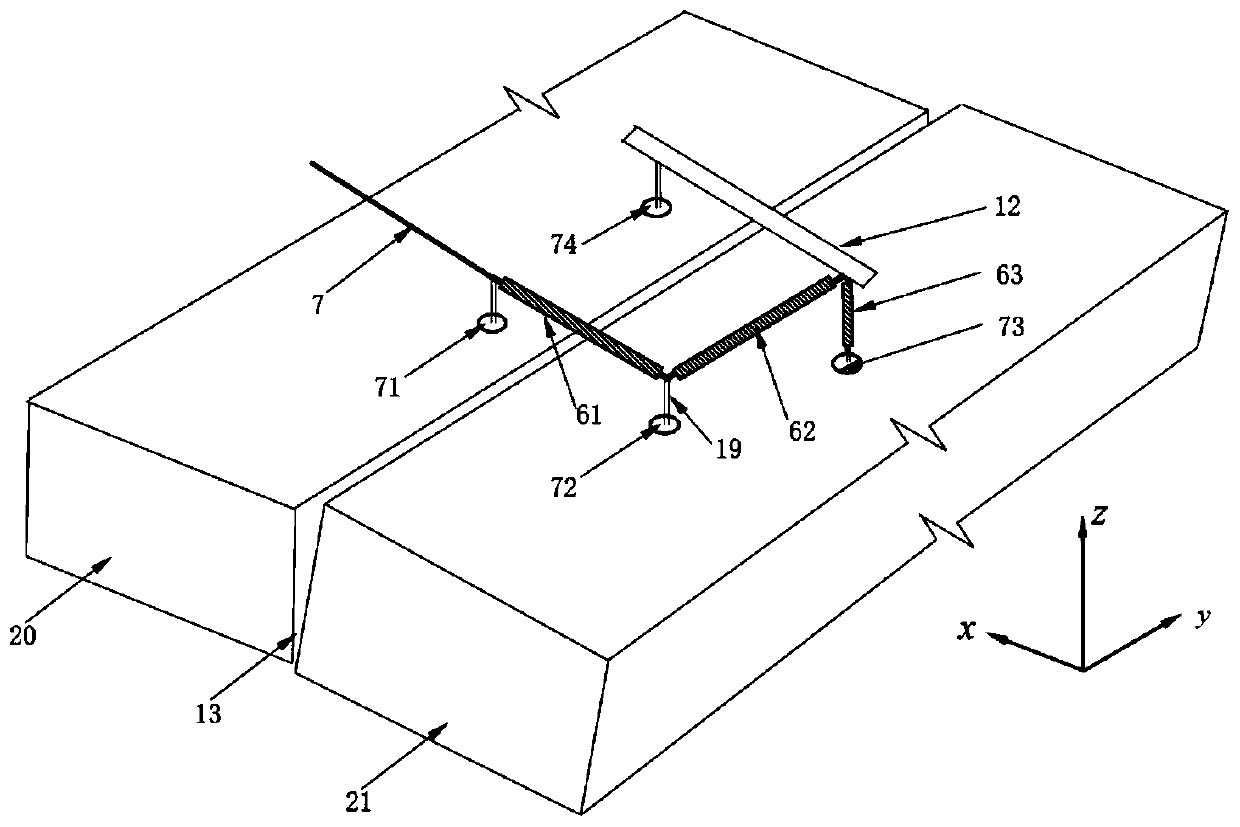

High-precision tunnel slab staggering positioning system and method based on low-coherence interference technology

ActiveCN111141219AThe production process is convenient and fastEfficient use ofUsing optical meansManufacturing technologyElectromagnetic interference

The invention aims to provide a high-precision tunnel slab staggering positioning system and method based on a low-coherence interference technology. The system comprises a broadband light source, a first optical fiber cable, a second optical fiber cable, a third optical fiber cable, a first coupler, a second coupler, three LCI displacement meters, an optical mobile scanning platform, an optical fiber with a flat tail end, and a signal collection and processing system. According to the invention, the 3D printing technology and the Michelson low-coherence interference technology are combined; the sensor has the advantages of convenience, quickness, low cost, improvement of the monitoring stability of the sensor and the like of a 3D printing manufacturing technology, also has the advantagesof high precision, strong electromagnetic interference resistance and suitability for long-term monitoring of tunnels of a low-coherence interference technology, and can be applied to engineering practical situations.

Owner:SHENZHEN UNIV

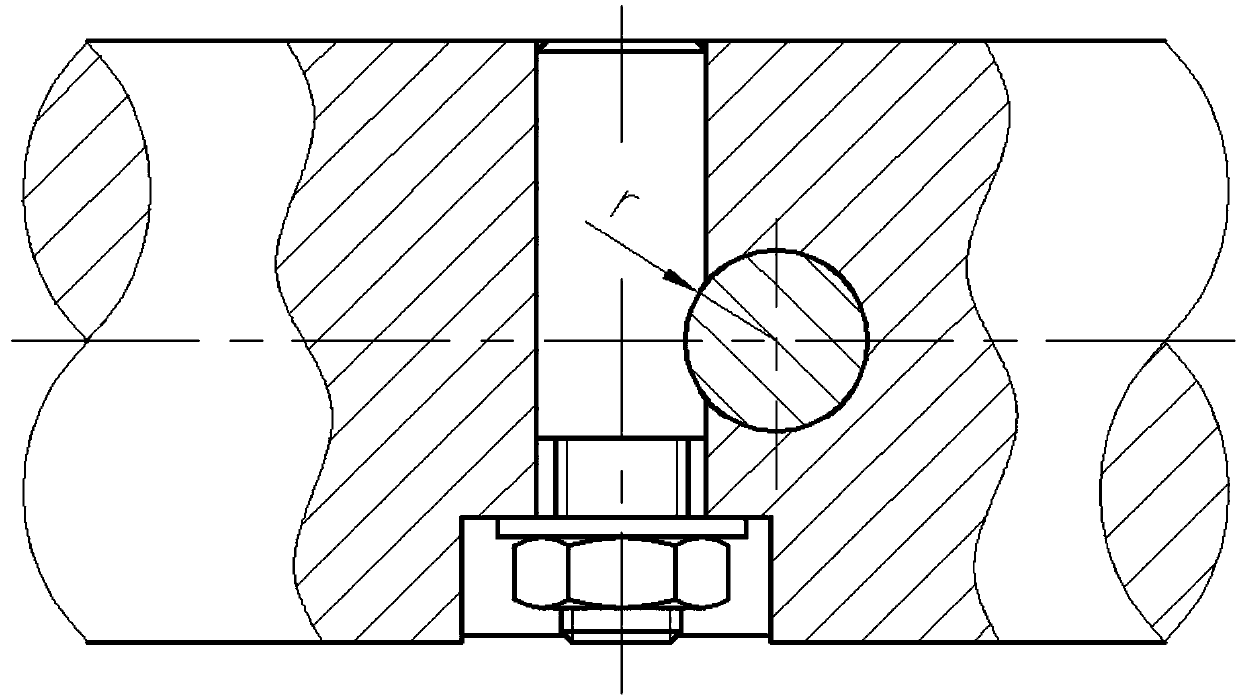

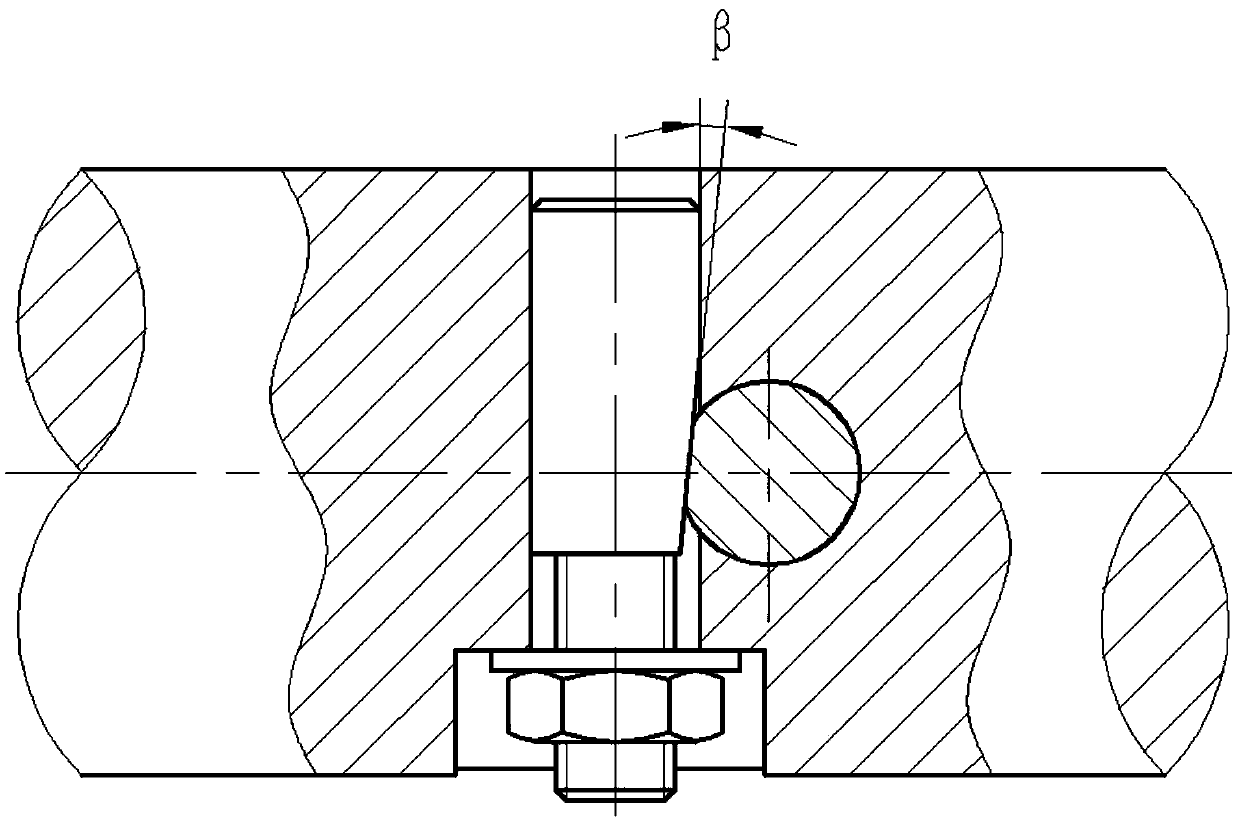

Double vertical clamping structure for finely adjusting double-worm-wheel fly cutter radially

PendingCN111283273AFlexible movementFlexible anti-rustWorm wheelsGear-cutting machinesEngineeringStructural engineering

The invention discloses a double vertical clamping structure for finely adjusting a double-worm-wheel fly cutter radially. A center hole which faces the active end and is concentric with a rotating central line of a cutter bar is formed in the passive end of the cutter bar, two parallel two-section stepped concentric holes for mounting, clamping and finely adjusting the fly cutter are radially formed along the rotating central line of the cutter bar, large holes of the two-section stepped concentric holes are cylindrical holes, small holes of the two-section stepped concentric holes are screwthrough holes, and the center distance between the two-section stepped concentric holes is the axial tooth pitch of a working worm; two sections of threads which are the same in screwing direction anddifferent in screw pitch are arranged on a locking screw and correspondingly connected with the screw through holes and a screw hole formed in a fly cutter round straight handle, so that the fly cutter is never loosened after being finely adjusted and clamped in the radial direction of the cutter bar; and a positioning clamping mechanism is arranged in the center hole, the oblique end faces of the opposite ends of a positioning jacking rod slide onto the obliquely-beveled plane of the fly cutter round straight handle to form close face contact under the combined action of the locking screw and a force applying component, and the fly cutter is fastened in the corresponding cylindrical hole and located at the correct position. The radial fine-adjusting and positioning double vertical clamping technical scheme is suitable for high-precision and large-cutting-force rolling cutting of multi-head worm wheels.

Owner:中钢集团衡阳机械有限公司

Scarless externally-applied medicine for burning and scalding injuries

InactiveCN103417697AReduce typesEasy to prepare and useHydroxy compound active ingredientsDermatological disorderBorneolBandage

The invention relates to scarless externally-applied medicine for burning and scalding injuries. The scarless externally-applied medicine is mainly made of raw materials comprising, by weight, 4-7 parts of multiflora rose roots, 0.2-0.5 part of borneol, 5-8 parts of licorice roots northwest origin, 20-50 parts of golden cypress and 2-4 parts of gypsum powder. The scarless externally-applied medicine is convenient and rapid to prepare and use as few categories of traditional Chinese medicine raw materials are adopted, bandage treatment is omitted after the medicine is applied to a wounded part, and the pain of a patient is relieved. The raw materials used in the medicine are compatible to one another and mutually promote efficacy, and thus time for curing is short. The scarless externally-applied medicine is effictive in treatment as no scars are left after treatment of class II burning and scalding injuries and only slight scars are left to a small number of patients after treatment of class III deep burning and scalding.

Owner:梅莉

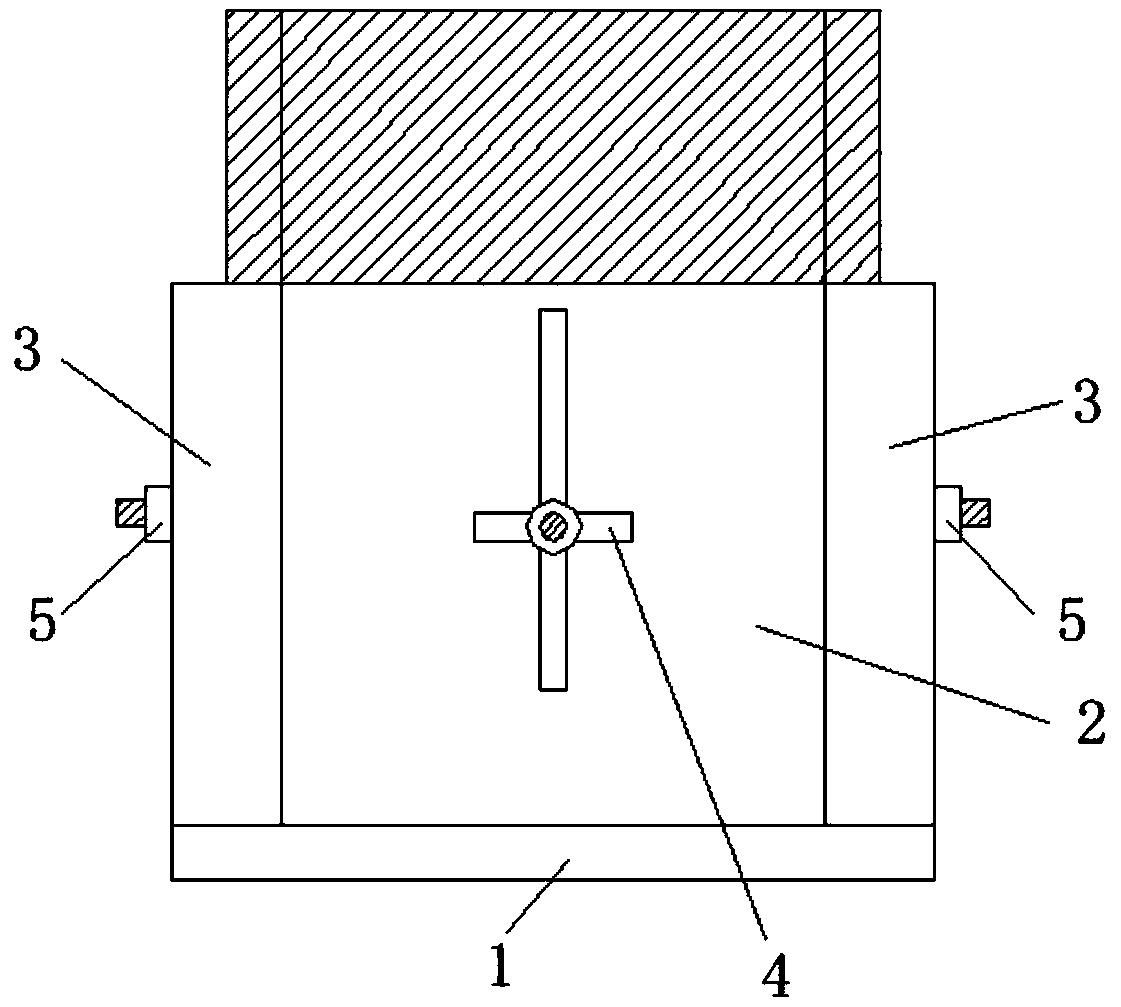

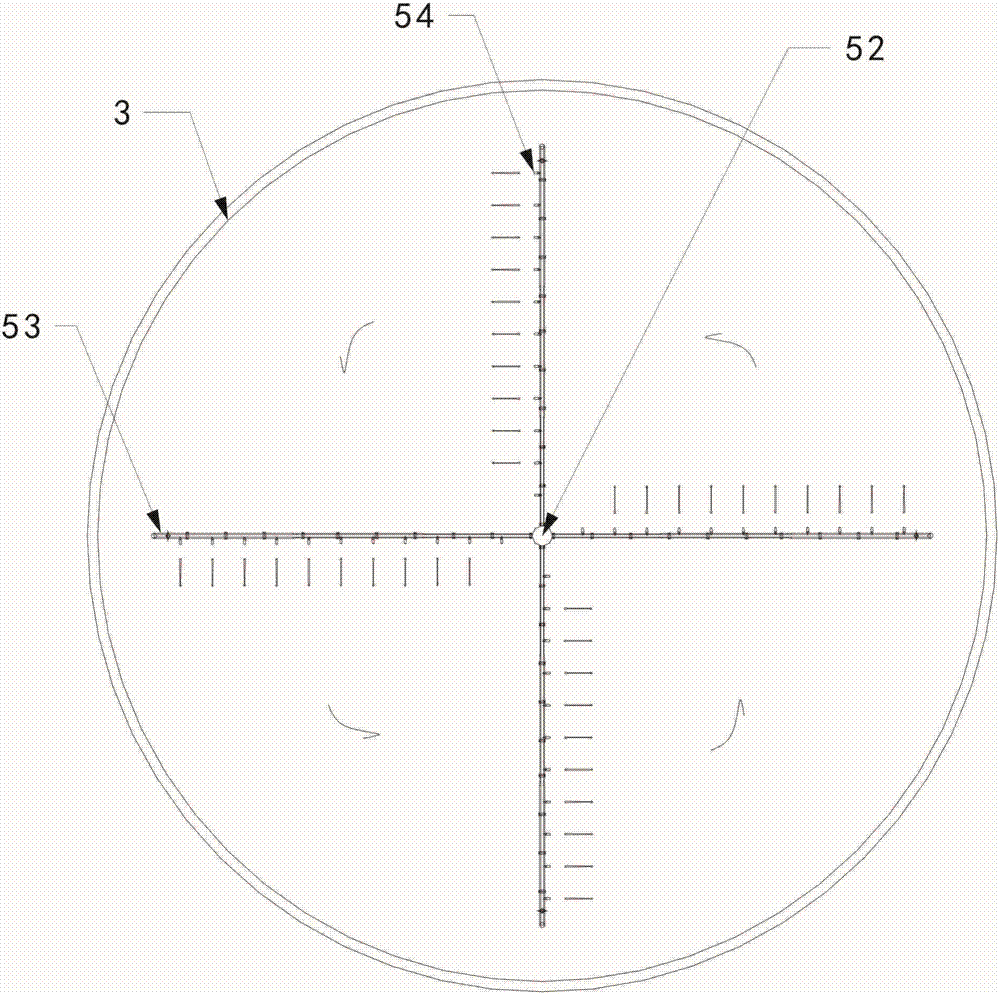

Matching device for manufacturing and direct shear test of soft interlayer with adjustable thickness of existing original rock structural surface

PendingCN109342137AAchieve preparationRealize the direct shear testPreparing sample for investigationStrength propertiesEngineeringDirect shear test

The invention provides a matching device for the manufacturing and a direct shear test of a soft interlayer with adjustable thickness of an existing original rock structural surface. The matching device comprises a bottom plate, A-type telescopic plates, scale rulers of A-type telescopic plate sliding blocks, B-type telescopic plates, and scale rulers of B-type telescopic plate sliding blocks. Thesurface of the bottom plate is square. The upper surface of the bottom plate is provided with telescopic plate positioning columns symmetrically arranged on the bottom plate. The telescopic plate positioning columns are used for fixing four telescopic plates. The bottom plate is a connecting plate of two A-type telescopic plates and two B-type telescopic plates. The two A-type telescopic plates and the two B-type telescopic plates have the same size and are symmetrically arranged on the bottom plate. According to the matching device, the problems that the soft interlayer of the existing original rock structural surface is difficult to manufacture and lay, and the thickness of the soft interlayer is difficult to adjust can be solved; and the test condition of whether the soft interlayer isextruded or not can be controlled in a direct shear test process.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

A corrugated foil mold and its manufacturing process

InactiveCN103341553BReduce processing costsPrecise positioningShaping toolsMechanical engineeringPolytetrafluoroethylene sheet

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Medicament for treating and preventing gynecological inflammation

InactiveCN101690799ARaw materials are easy to obtainThe production process is convenient and fastAnthropod material medical ingredientsUrinary disorderGynecologyInflammation

The invention provides a medicament for treating and preventing gynecological inflammation, which mainly comprises the following components of tea leaves, shredded ginger and pricklyash peel in a weight ratio of 4:2-3:1-2. Honey can also be added into the medicament, and accounts for 0.5 to 1 part based on the dosage of other components. The invention also provides a preparation method for the medicament, for example, the conventional crushing and mixing or direct mixing for obtaining a solid product, or the extracting (crushing before extracting or no crushing) for obtaining a mixed extract product and the like can be used for obtaining the medicament of the invention. The usage method for the medicament comprises fumigating, washing, and a combination of the fumigating and washing.

Owner:徐星

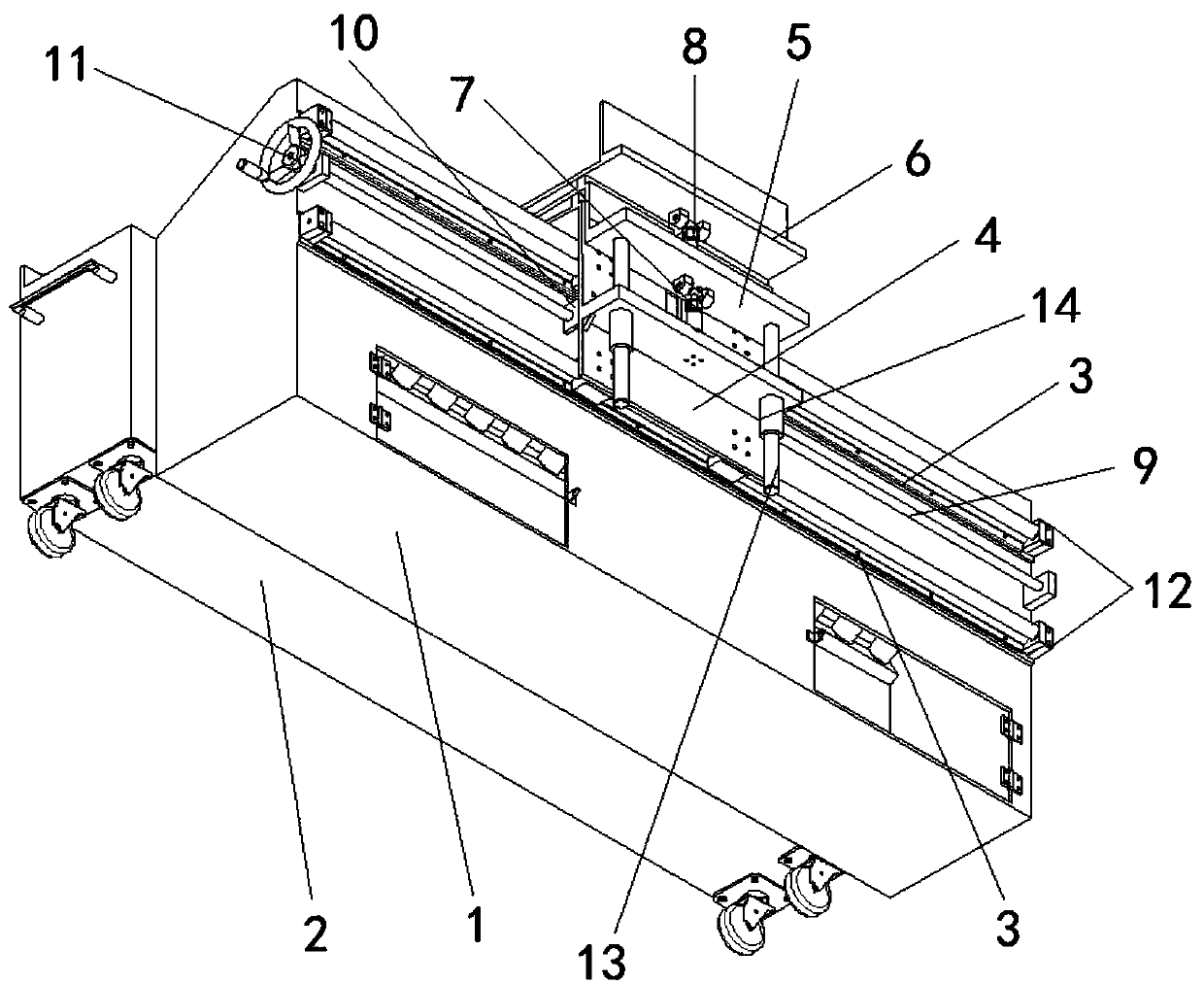

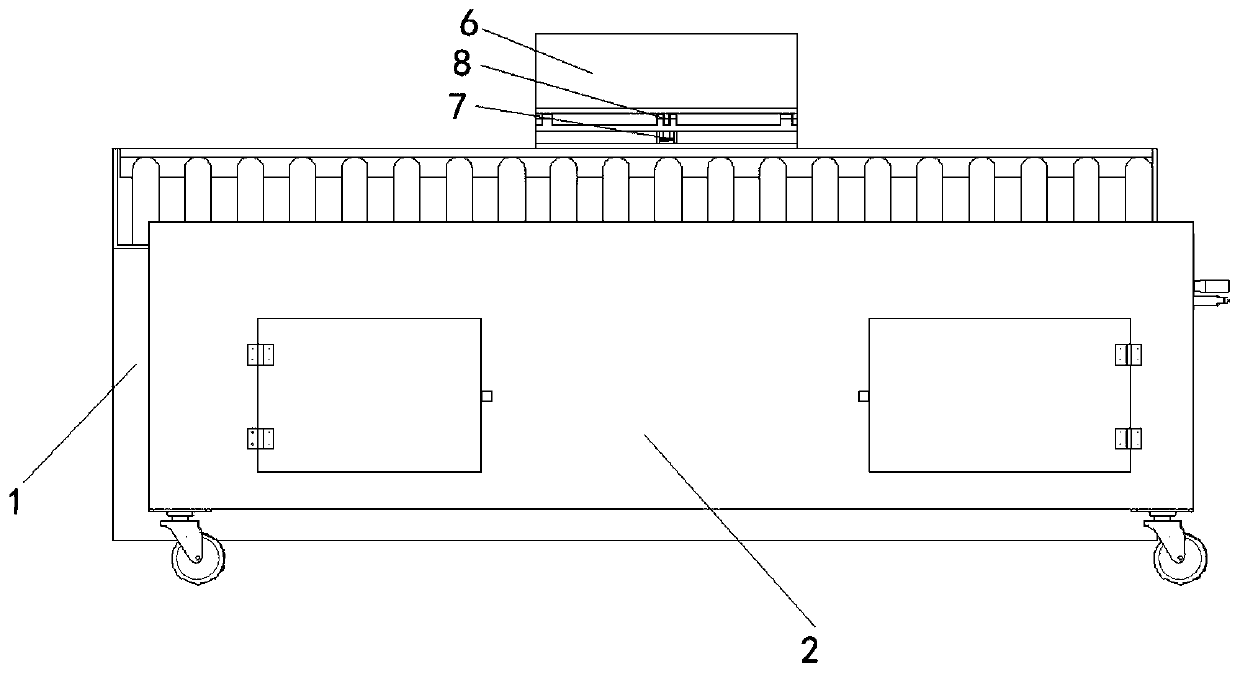

Waste discharging device of laser cutting machine

The invention discloses a waste discharging device of a laser cutting machine. The waste discharging device comprises a car body, a plurality of guide wheels, pulley fixing seats, pulleys, wherein the surface of the car body is recessed, a handle is installed at one end of the car body, annular rubber tires are installed on the surfaces of the guide wheels, the guide wheels are symmetrically installed on two sides of the car body, the pulley fixing seats are installed on the bottom face of the car body, and rotating devices are installed between the pulley fixing seats and the car body, annular rubber tires provided with protrusions on the surfaces are installed on the surfaces of the pulleys, and the pulleys are installed on the pulley fixing seats. By means of the mode, the waste discharging device of the laser cutting machine is compact and simple in structure, small in size, convenient and fast to manufacture and install, low in cost, high in performance cost ratio and convenient to use and maintain.

Owner:SUZHOU HUIFENG MACHINERY EQUIP

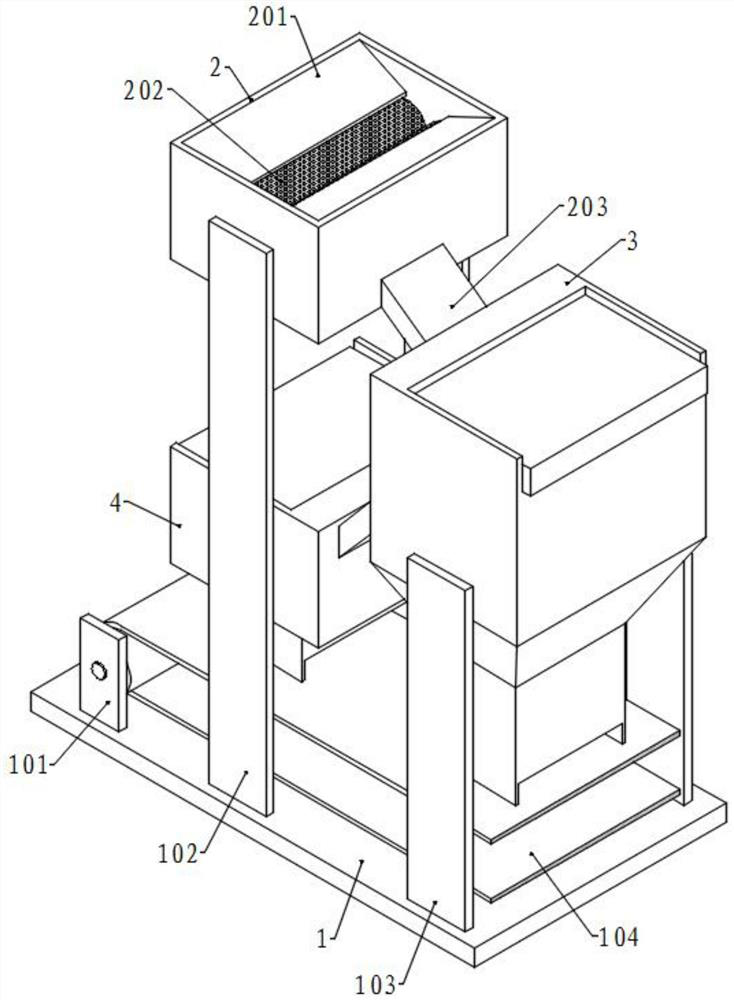

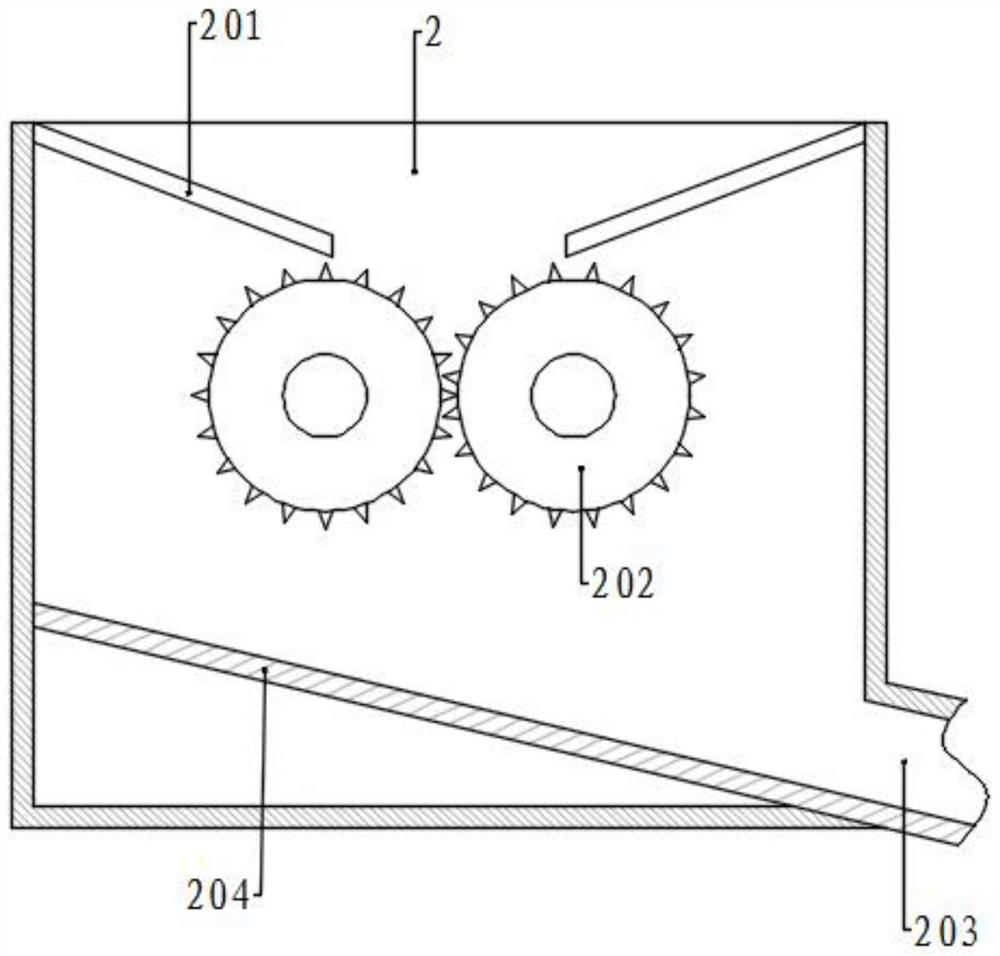

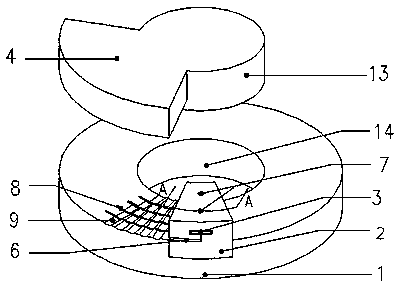

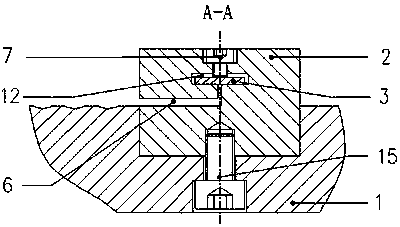

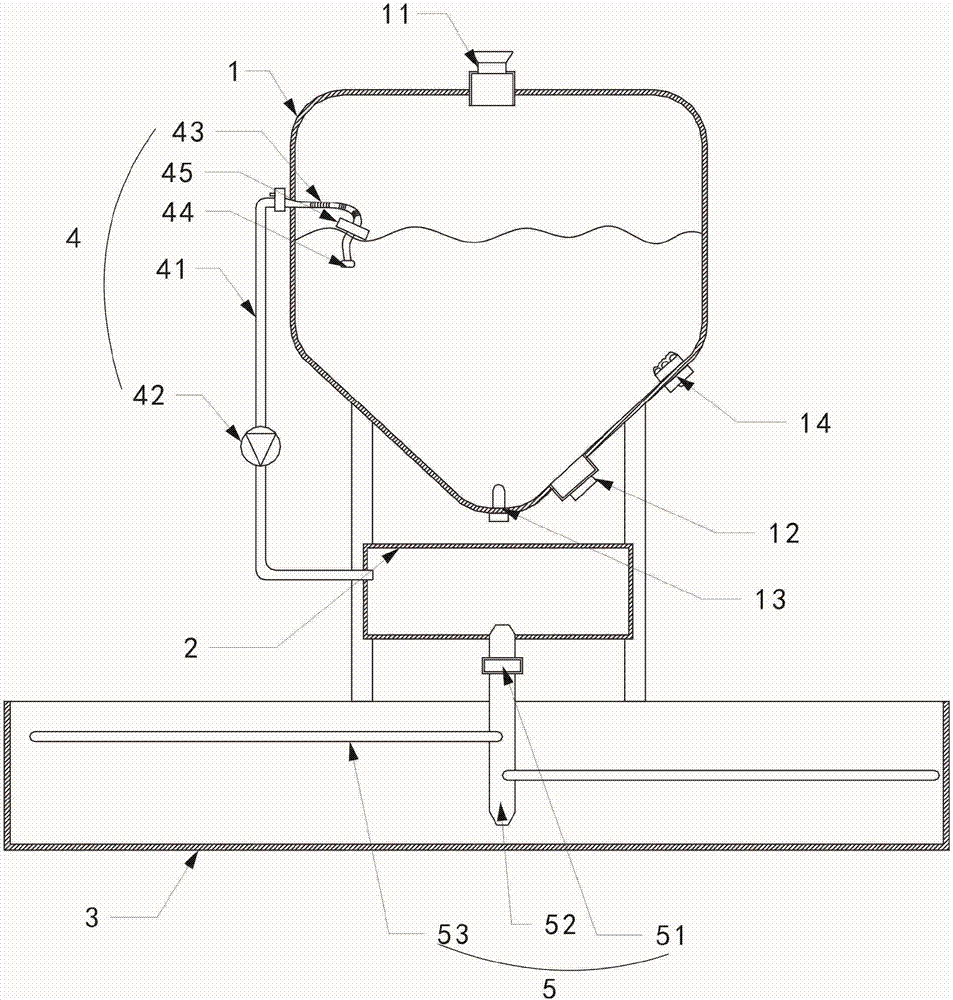

Preparation device and method of sodium carbonate and ammonium sulfate by anhydrous sodium sulphate

PendingCN107572562AEasy to adjust controlThe production process is convenient and fastProductsReagentsTemperature controlSulphate Ion

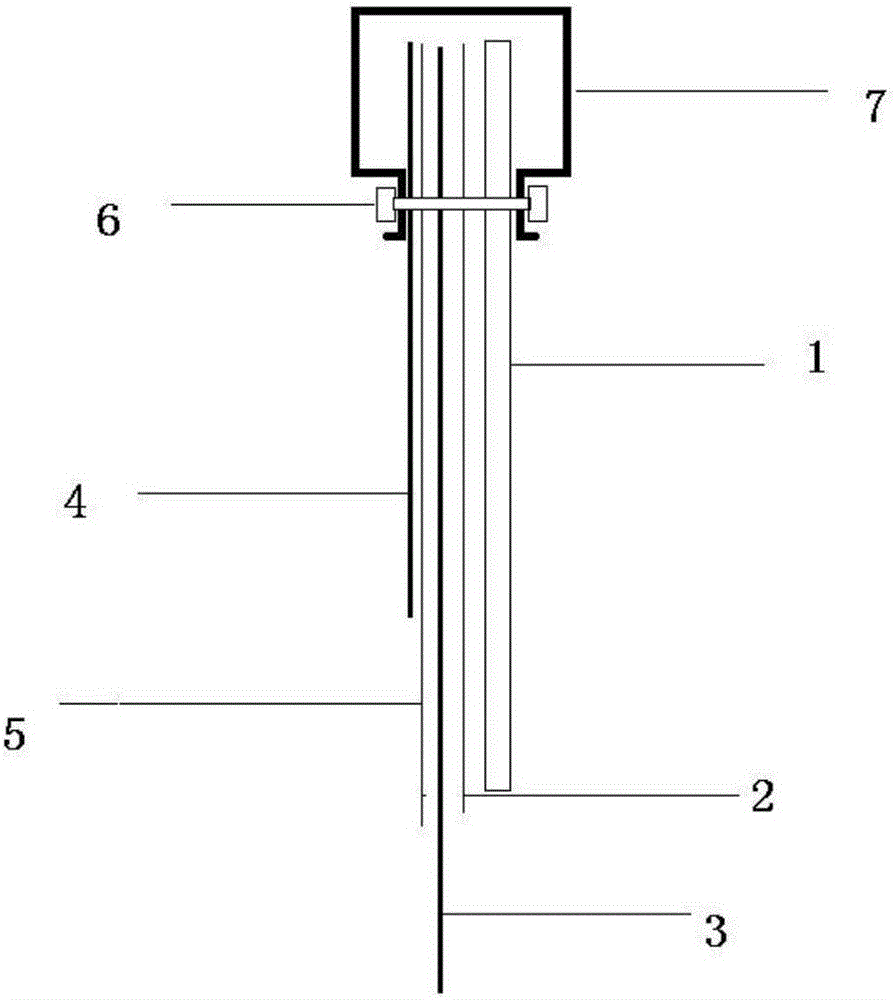

The invention discloses a preparation device of sodium carbonate and ammonium sulfate by anhydrous sodium sulphate and a preparation method, and relates to the technical field of alkali preparation. The device comprises a reaction kettle (1), a temperature control box (2), a mixing tank (3), and an extracting mechanism (4) used for conveying middle fluid; the reaction kettle (1) is installed abovea bracket leg (5), and the temperature control box (2) is fixed on the bracket leg (5); the extracting mechanism (4) is connected with the reaction kettle (1) and the temperature control box (2). Themethod includes steps of step 1, raw material pretreatment; step 2, separation out of heavy metals; step 3, secondary adjustment of solution; step 4, replacement reaction; step 5, separation by crystallization. Through the device and the method, the temperature in reaction is more convenient to adjust and control; the preparation flow is more convenient and faster.

Owner:四川省洪雅青衣江元明粉有限公司

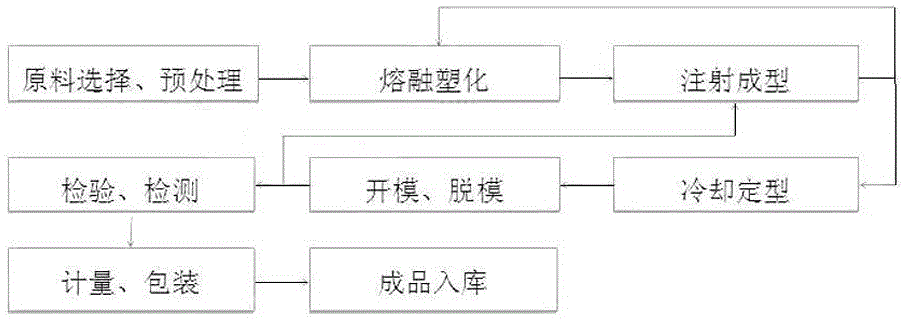

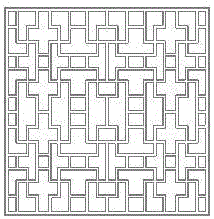

Manufacturing method for injection molding alloy material hollowed-out checkered plate

InactiveCN106273208AReduce labor intensityLower skill requirementsFlat articlesMolten stateMolten alloy

The invention discloses a manufacturing method for an injection molding alloy material hollowed-out checkered plate. The method includes the following steps that melt plastification is performed, an alloy material is heated to 220-250 DEG C, and then the alloy material in a molten state for standby application; injection molding is conducted, and the molten alloy material is injected into a mold within 8-10 seconds in an injection mode under the conditions that the pressure is 85-110MPa and the flow is 85%-90%; cooling and demolding are carried out, the mold filled with the alloy material is subjected to overall demolding after being cooled, and thus the hollowed-out checkered plate is obtained; and the melting point of the alloy material ranges from 170 DEG C to 220 DEG C. By the adoption of the manufacturing method, products can be obtained in the one-time injection molding mode, and the method is suitable for large-scale batch production. The obtained hollowed-out checkered product is lasting in color, non-toxic and harmless in material, safe, environmentally friendly and capable of being cleaned easily. The hollowed-out checkered plate cannot be deformed after being used for a long time, color fading is not likely to happen, and installation is convenient.

Owner:邓利民

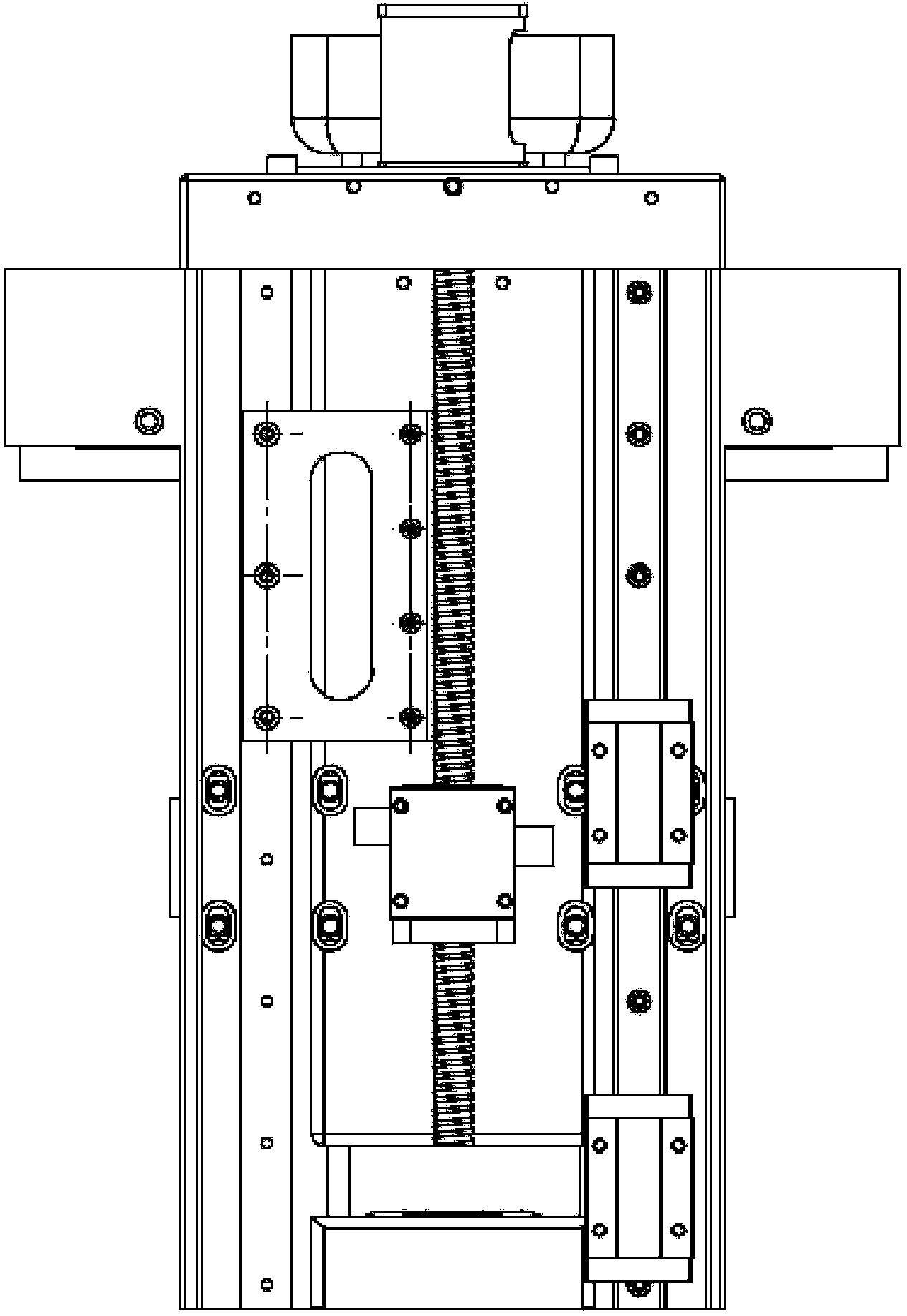

Tool piece and process for assembling Z-axis lead screw of laser cutting machine

ActiveCN103537808ACompact structureReduce volumeLaser beam welding apparatusLaser cuttingEngineering

The invention relates to a tool piece for assembling a Z-axis lead screw of a laser cutting machine. The tool piece comprises L-shaped angle steel piece with two perpendicular faces, and a rectangular body with a stair-shaped cross section, wherein positioning screw holes are formed in the left side of the rectangular body, connecting screw holes are formed in the right side of the rectangular body, and edges of the rectangular body are connected with the L-shaped angle steel piece. According to the tool piece, a linear guide rail installation face serves as a standard, the parallelism degree of the lead screw and a linear guide rail is ensured, the device can more accurately and stably run, the service life of the device is prolonged, installation time of workers is greatly shortened, assembly accuracy of the workers is greatly lowered, and work efficiency is improved.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

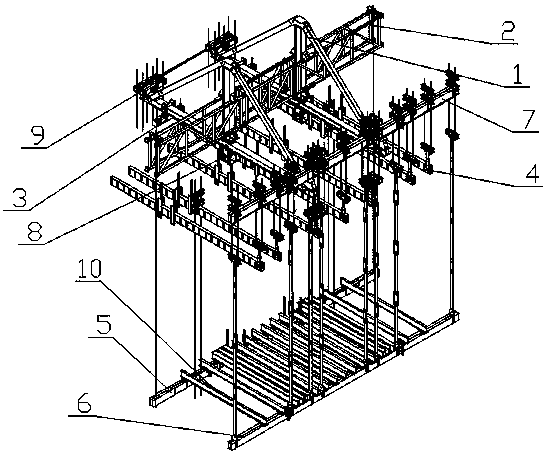

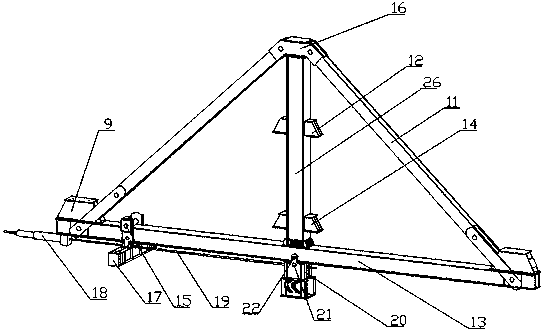

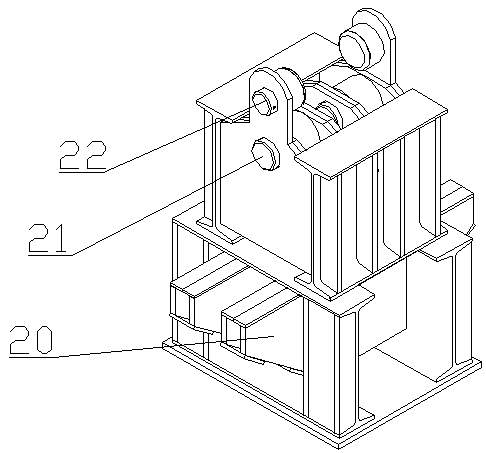

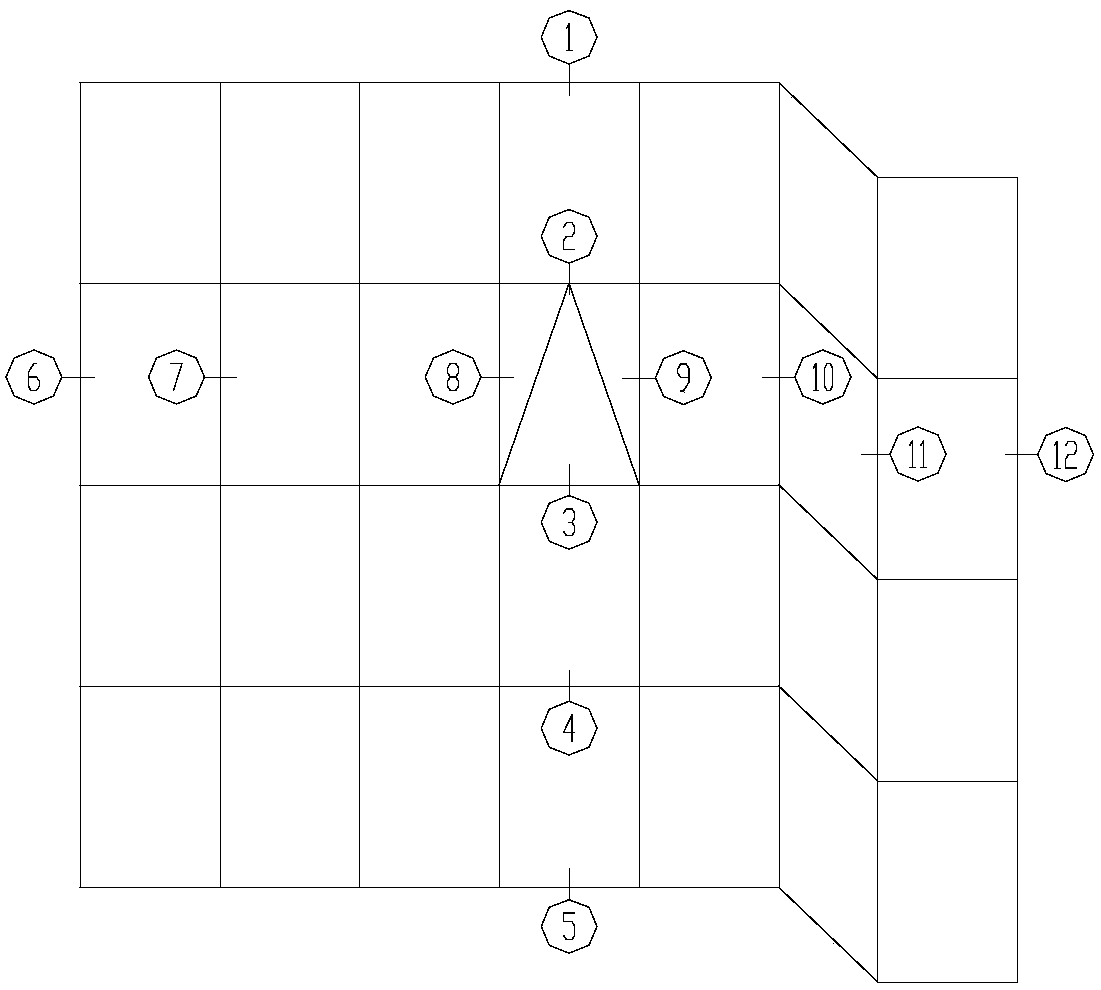

Trackless type triangle hanging basket

PendingCN108589554ASave steelSimplified walking procedureBridge erection/assemblyCable stayedHanging basket

The invention discloses a trackless type triangle hanging basket. The trackless type triangle hanging basket comprises a main truss system, a reverse hanging system, a supporting system (8) and a bottom basket system. The reverse hanging system, the supporting system (8) and the bottom basket system are installed on the lower portion of the main truss system. The trackless type triangle hanging basket is characterized in that the main truss system comprises two triangular main trusses (1) disposed at two ends of a lateral connecting truss (2) and a front upper cross beam (7) at the front end,and each triangular main truss (1) includes a stand column (26), a main longitudinal beam (13) and back anchors (9); the stand columns (26) are detachably supported on the main longitudinal beams (13), and the two ends of cable-stayed steel belts (11) are separately connected to the tops of the stand columns (26) and the end portions of the main longitudinal beams (13) in a relatively rotating mode; and the main longitudinal beams (13), the stand columns (26) and the cable-stayed steel belts (11) form a triangle, and the back anchors (9) are fixedly arranged on the tail portions of the main longitudinal beams (13). The trackless type triangle hanging basket is convenient to walk, safe and efficient, simple in structure and convenient to assemble and disassemble, and is suitable for the popularization and use of the construction of a suspending cast box beam by the trackless triangle hanging basket.

Owner:GUIZHOU ROAD & BRIDGE GRP

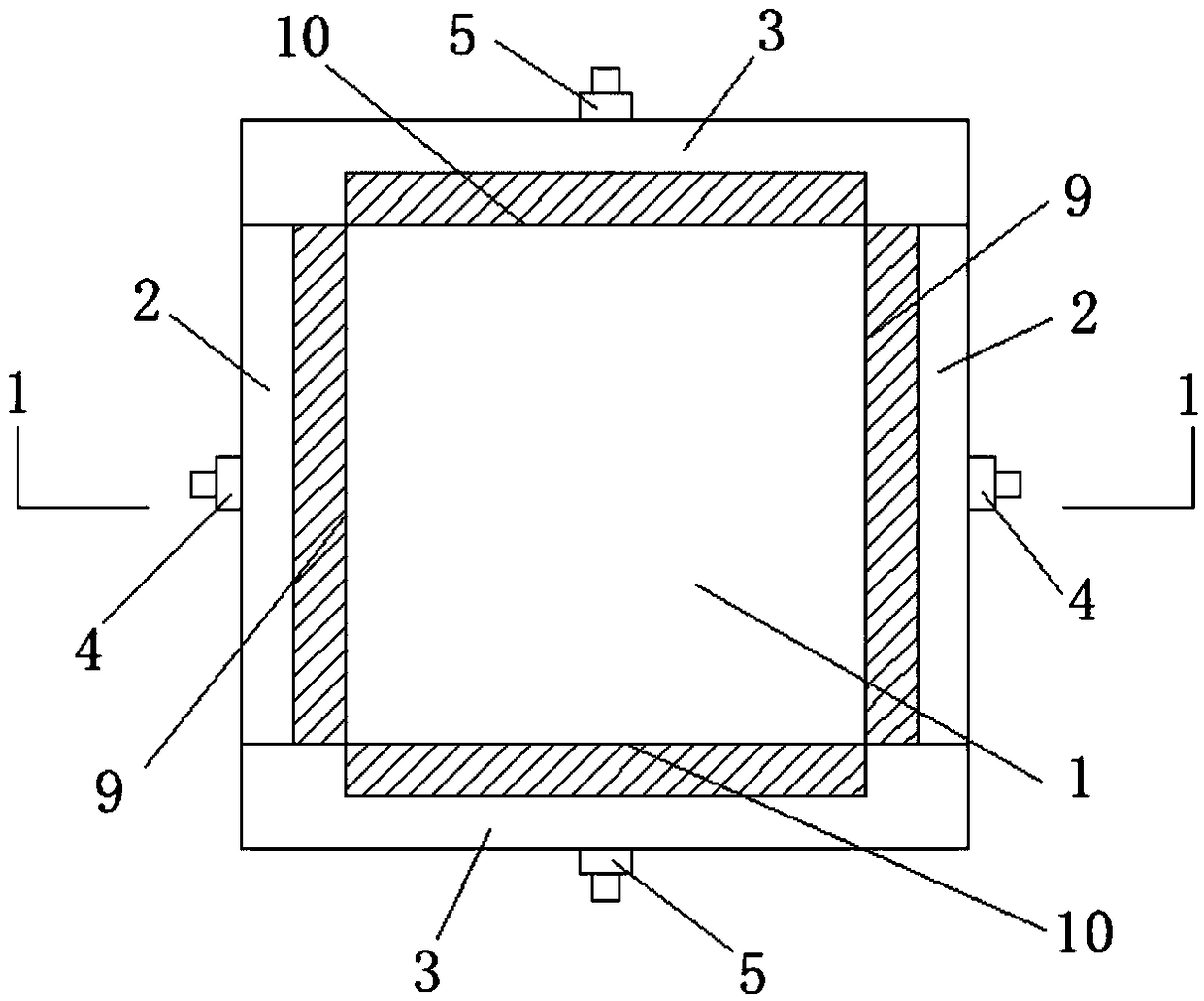

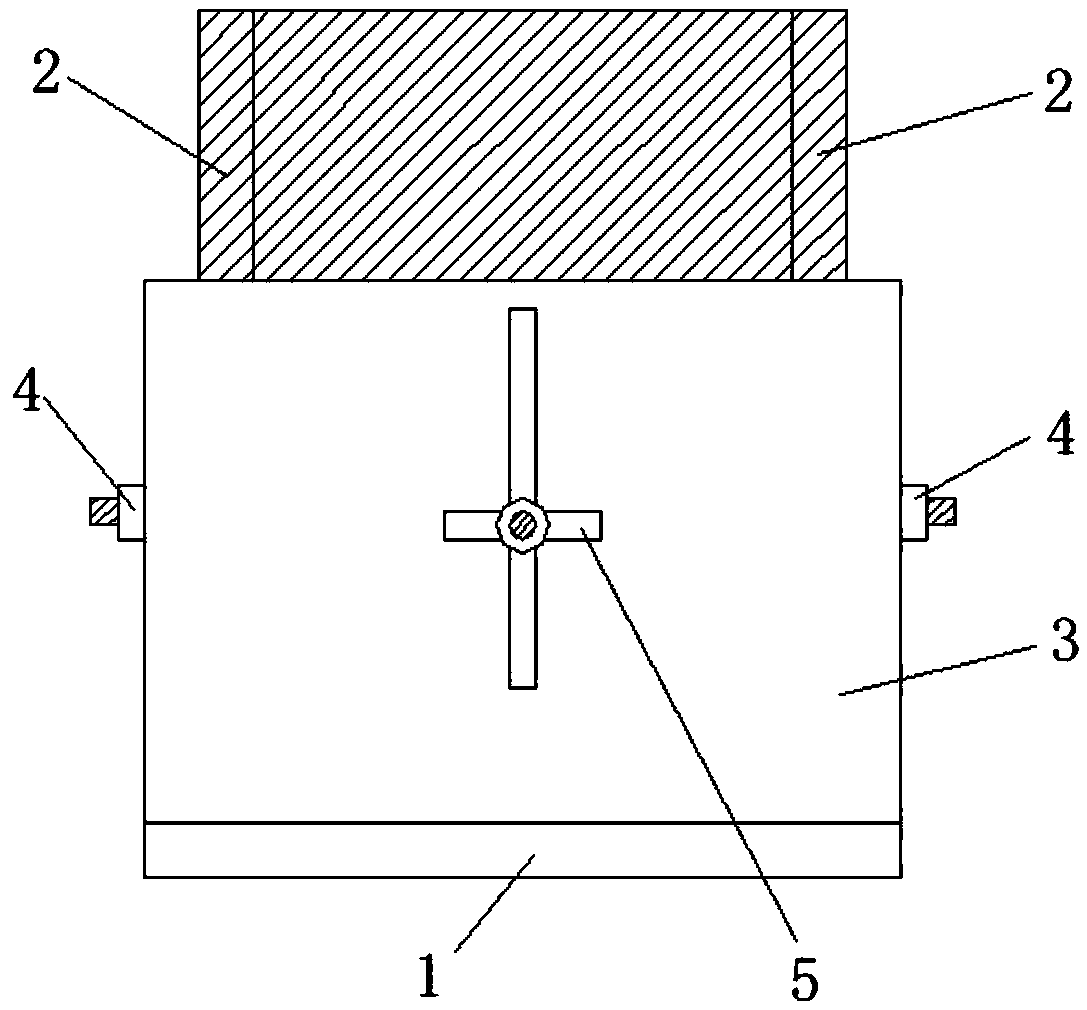

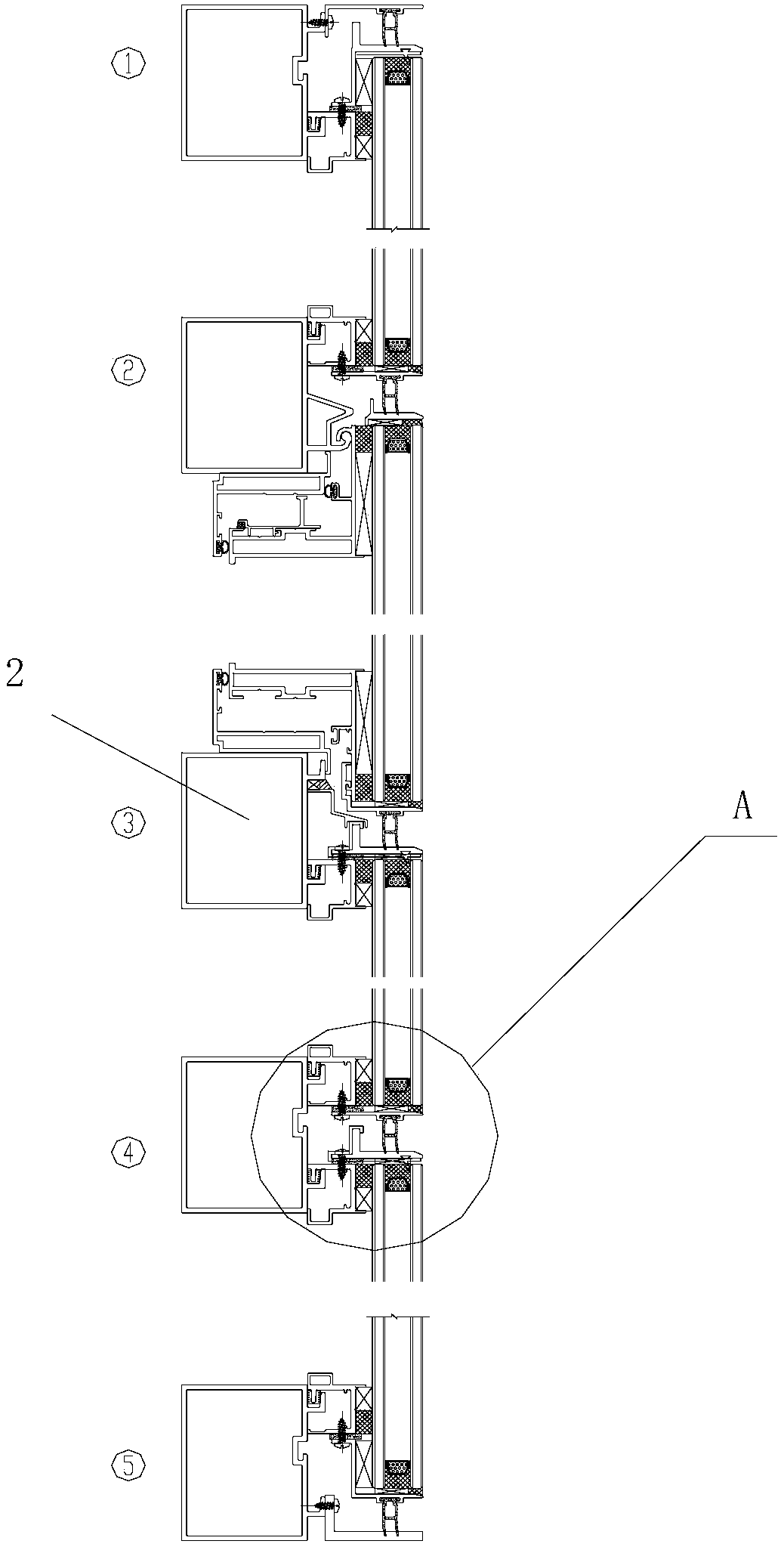

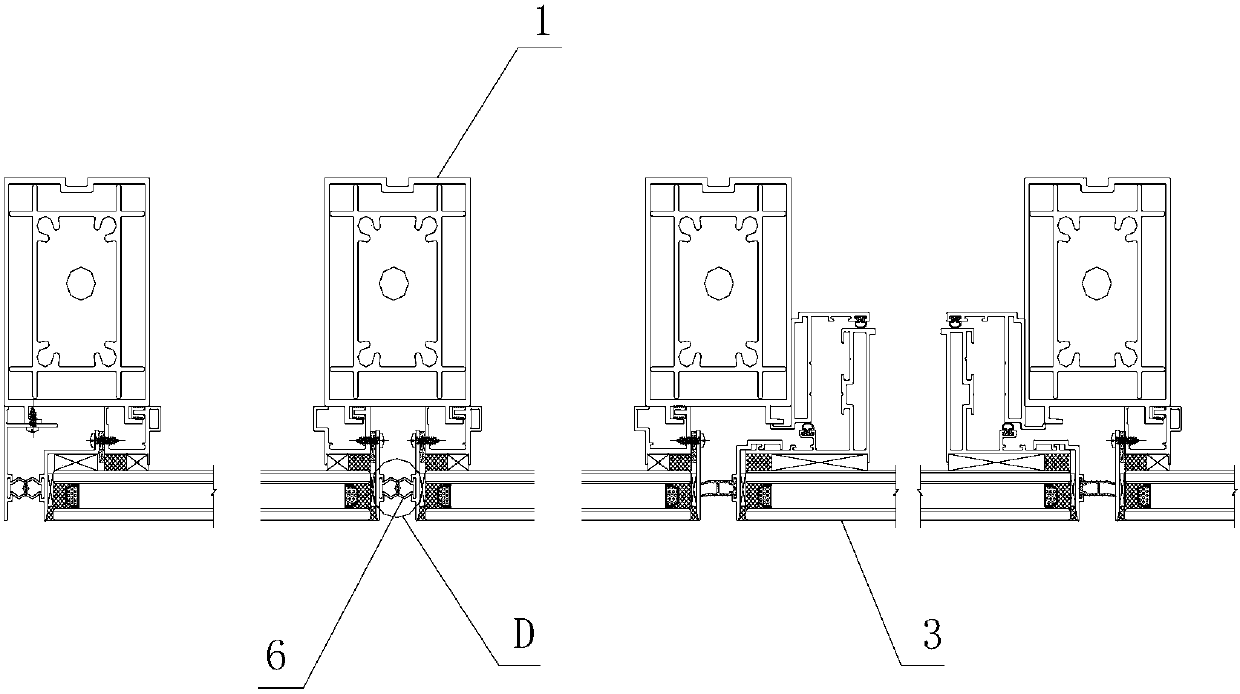

A Component Curtain Wall System Suitable for Dry Construction

ActiveCN105625617BChange the installation methodRealize dry constructionWallsBuilding insulationsWater leakageEngineering

A stick curtain wall system suitable for dry construction, comprising: mullions (1), transoms (2) connected to the mullions (1), and panels (3) mounted on the mullions (1) and the transoms (2). Several joint accessories (4) and several first sealing strips (6) are provided within vertical gaps formed by the panels (3); the first sealing strip (6) is mounted between two adjacent joint accessories (4); a waterstop strip (9) is provided on the top of each panel (3), and a second sealing strip (10) is provided at the bottom of each panel (3); the joint accessory (4) is horizontally mounted on the tops of two adjacent panels (3) to partition the vertical gaps; both ends of the joint accessory (4) are in engagement joint with the ends of the waterstop strip (9); a sealing layer (5) sealably connected with the ends of the waterstop strip (9) is further provided on the joint accessory (4). The mounting approach of the stick curtain wall is greatly changed. The joint accessories (4), the sealing layers (5), and the first sealing strips (6) are organically combined with the second sealing strips (10) and the waterstop strips (9) to form specific waterstop, flashing, and draining structures, thereby effectively solving the water leakage problem, and practically implementing the dry construction of a stick curtain wall.

Owner:杜军桦 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com