Flocculation device for continuous electric field assisted wet rubber mixing and rubber mixing equipment with flocculation device

An electric field-assisted and flocculation device technology is applied in the field of rubber processing machinery, which can solve the problems of consuming a large amount of water resources, difficult to form automatic production, and difficult to treat wastewater containing acid water, and achieve the effect of improving flocculation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to detail the technical content of the present invention, the objectives and effects achieved, and the following combined embodiments will be described.

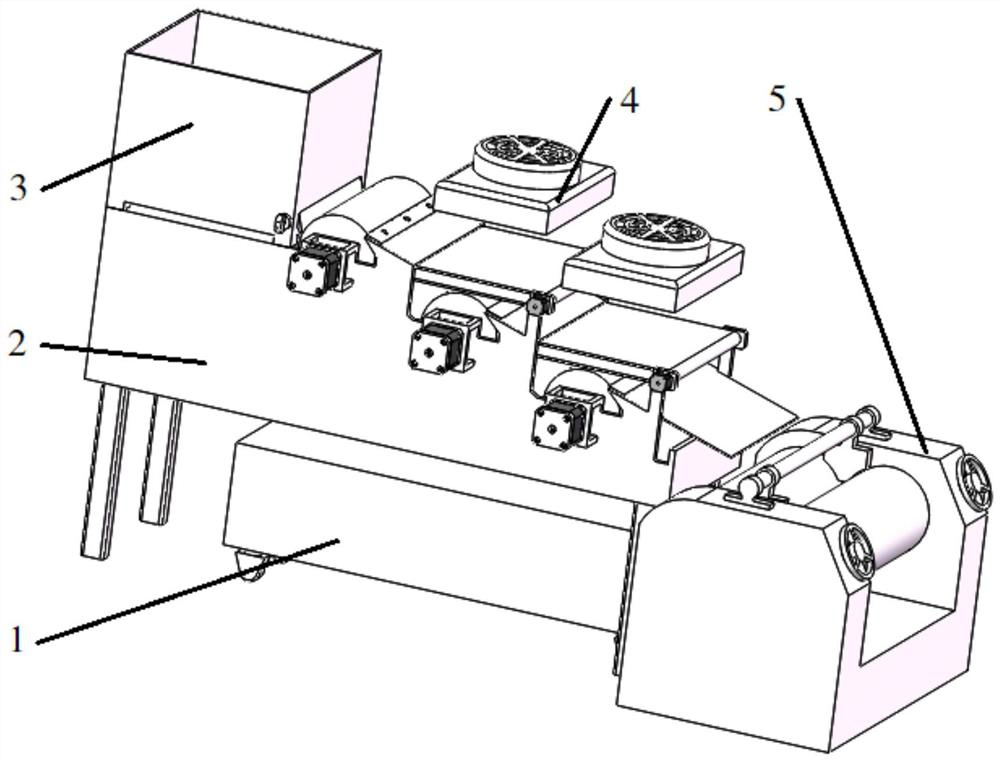

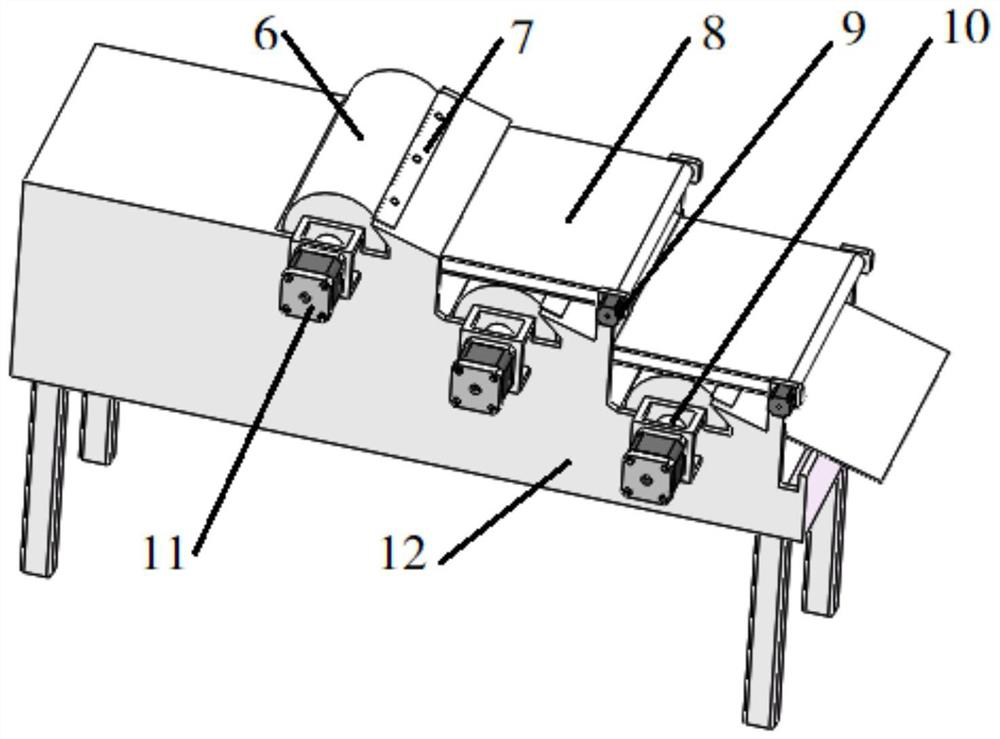

[0029] According to one embodiment of the invention, a flocculation device for continuous electric field auxiliary wet rubber is provided, such as figure 1 , 2 As shown, including the roller 6, the splinker 7, the conveyor belt 8, the conveying motor 9, the coupling 1010, the stepping motor 11, the frame 12, the stepping motor 11, and the conveying motor 9 are fixed to the rack 12 by the screws 12, The stepper motor 11 is connected to the roller 6 via a coupling 10, and the splitter 7 is secured to the frame 12 by a bolt, and the conveying motor 9 is connected to the conveyor belt 8.

[0030] Due to the negative charge due to the latex particles, when the roller 6 with a positive charge is touched, the protective case outside the latex is loses stable flocculation. After the latex is flocculated with positively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com