Adhesive and composition and application thereof

A technology of adhesives and compositions, applied in the direction of film/sheet adhesives, non-polymer adhesive additives, adhesives, etc., which can solve the problem of inability to use adhesive reel display components and the impact of anti-rebound performance The durability of curved surface bonding, the anti-rebound performance of the adhesive sheet is not ideal, etc., to achieve excellent anti-rebound performance, durable curved surface bonding, and the effect of absorbing continuous stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

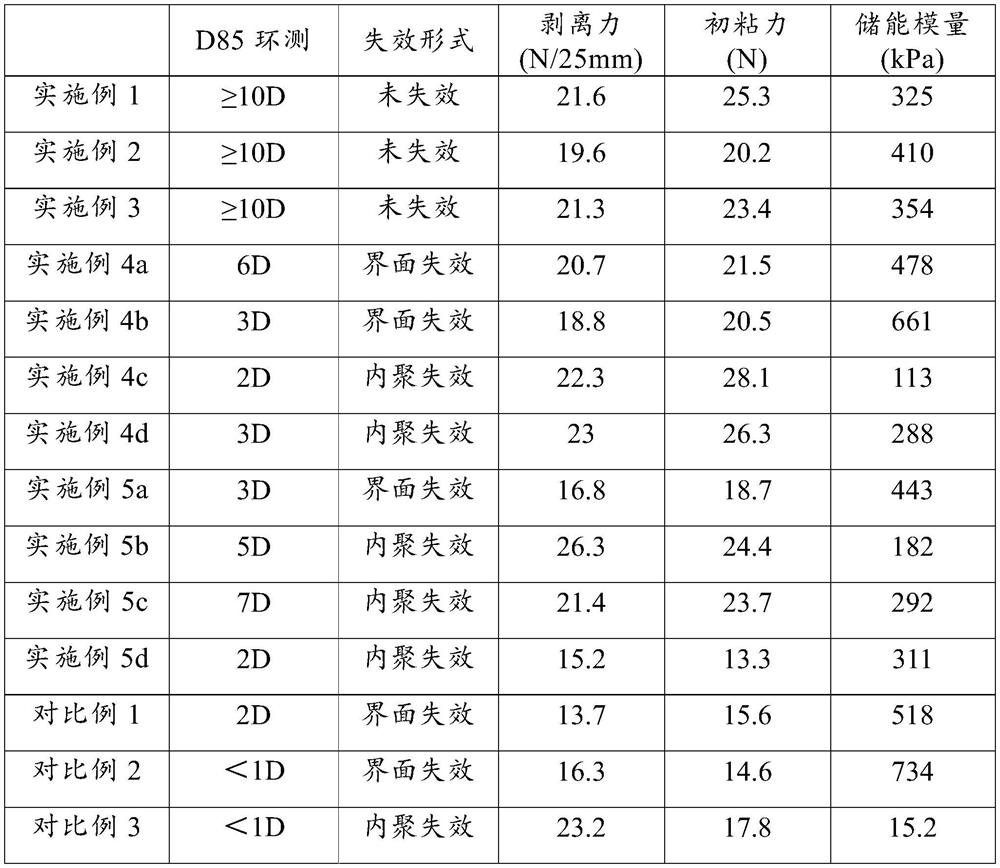

Examples

Embodiment 1

[0065] (1) Prepare the composition

[0066] A component: a total of 100 parts by weight, including 90 parts by weight of triblock copolymer a1 (block ratio is 22 / 78, diblock content is 15%, tensile strength is 20MPa, hardness is 45 Shore A, line type structure), 10 parts by weight of a-type triblock copolymer a2 (block ratio is 15 / 85, diblock content is 19%, tensile strength is 21MPa, hardness is 32 Shao A, linear structure);

[0067] Component B: a total of 25 parts by weight, including 15 parts by weight of terpene phenolic resin (about 150°C in softening point) and 10 parts by weight of terpene resin (about 120°C in softening point);

[0068] Antioxidant: a total of 1.5 parts by weight, including the antioxidant HPA (hindered phenols) of 1 part by weight and the second antioxidant PPA (phosphite esters) of 0.5 parts by weight;

[0069] Curing agent: a total of 1 part by weight, which is an isocyanate curing agent ICA;

[0070] Organic solvent: a mixture of toluene and n-h...

Embodiment 2

[0077] (1) Prepare the composition

[0078] A component: total 100 parts by weight, including the triblock copolymer a1 (same as embodiment 1) of 100 parts by weight;

[0079] Component B: a total of 20 parts by weight, including 12 parts by weight of terpene phenol resin (softening point about 140°C) and 8 parts by weight of terpene resin (softening point about 110°C);

[0080] Antioxidant: a total of 1 part by weight, including the antioxidant HPA (hindered phenols) of 0.7 parts by weight and the second antioxidant PPA (phosphite esters) of 0.3 parts by weight;

[0081] Curing agent: a total of 1 part by weight, which is an isocyanate curing agent ICA;

[0082] Organic solvent: a mixture of toluene and n-heptane at a volume ratio of 1:1.

[0083] (2) Preparation of adhesive

[0084] Mixing the prepared composition and stirring to dissolve each component in an organic solvent to obtain an adhesive glue;

[0085] Use a knife coater to coat the adhesive glue solution on the...

Embodiment 3

[0089] (1) Prepare the composition

[0090] A component: a total of 100 parts by weight, including 95 parts by weight of triblock copolymer a1 (same as Example 1), 5 parts by weight of triblock copolymer a2 (same as Example 1);

[0091] Component B: 25 parts by weight in total, including 10 parts by weight of the first terpene resin (softening point about 160°C) and 15 parts by weight of the second terpene resin (softening point about 120°C);

[0092] Antioxidant: a total of 1.5 parts by weight, including the antioxidant HPA (hindered phenols) of 1 part by weight and the second antioxidant PPA (phosphite esters) of 0.5 parts by weight;

[0093] Curing agent: a total of 1 part by weight, which is an isocyanate curing agent ICA;

[0094] Organic solvent: a mixture of toluene and n-heptane at a volume ratio of 1:1.

[0095] (2) Preparation of adhesive

[0096] Mixing the prepared composition and stirring to dissolve each component in an organic solvent to obtain an adhesive gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com