Penetration enhancer for fracturing as well as preparation method and application thereof

A permeation enhancer and fracturing technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low imbibition capacity and permeation enhancement capacity of chemical agents, and achieve high imbibition capacity and high permeation enhancement ability. ability, the effect of low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

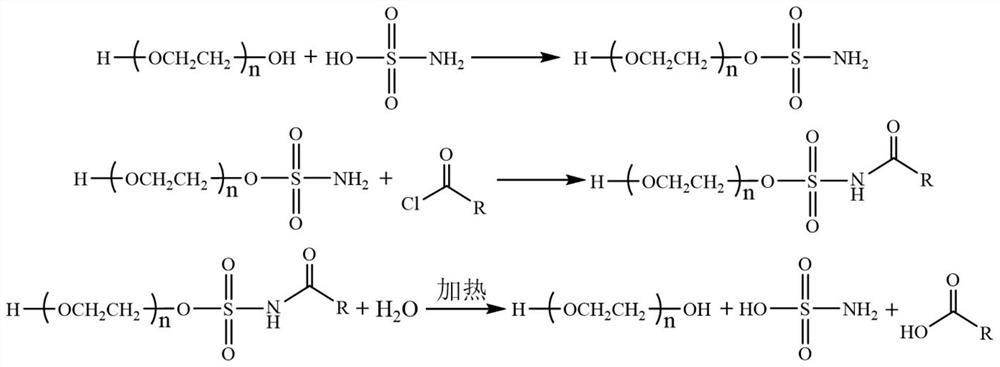

[0038] A method for preparing a permeation enhancer for fracturing, comprising the following steps:

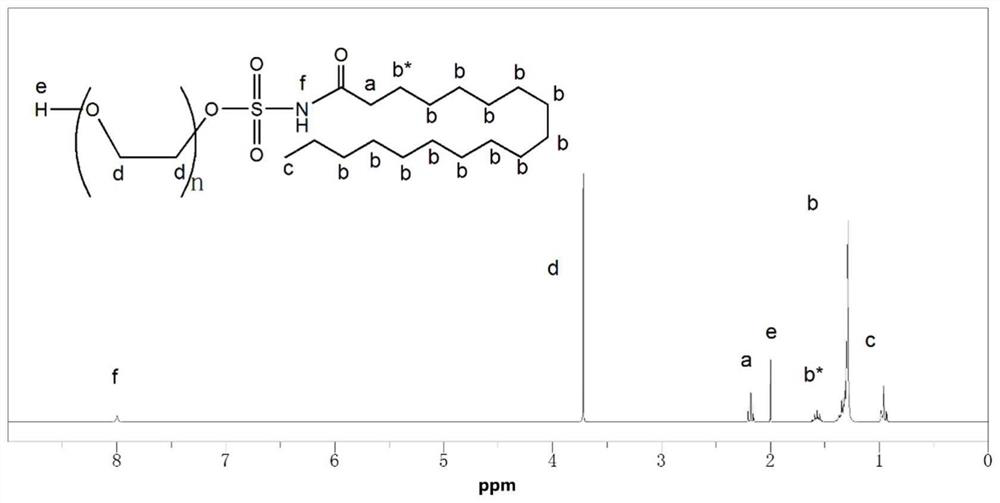

[0039] Mix 9.7g of sulfamic acid and 45.8g of polyoxyethylene (n=10) in 429.0g of solvent dimethylformamide for the first reaction, raise the temperature to 95°C, and react for 2h to obtain a mixed solution. After the reaction is over, control the temperature at 30°C, then add 30.3 g of octadecyl chloride to the reacted mixed solution for the second reaction, react for 4 hours, obtain the reaction solution, concentrate the reaction solution, and use toluene column chromatography The product was purified and separated by the method, and vacuum-dried to constant weight to obtain a permeation enhancer for fracturing, which is polyoxyethylene octadecyl amidosulfonate.

Embodiment 2

[0041] A method for preparing a permeation enhancer for fracturing, comprising the following steps:

[0042] Mix 9.7g of sulfamic acid and 45.8g of polyoxyethylene (n=10) in 415.0g of solvent dimethylformamide for the first reaction, raise the temperature to 95°C, and react for 2h to obtain a mixed solution. After the reaction is finished, control the temperature at 30°C, then add 27.5 g of octadecyl chloride to the reacted mixed solution for the second reaction, react for 4 hours, obtain the reaction solution, concentrate the reaction solution, and use toluene column chromatography The product was purified and separated by the method, and vacuum-dried to constant weight to obtain a permeation enhancer for fracturing, which is polyoxyethylene octadecyl amidosulfonate.

Embodiment 3

[0044] A method for preparing a permeation enhancer for fracturing, comprising the following steps:

[0045] Mix 10.7g of sulfamic acid and 45.8g of polyoxyethylene (n=10) in 520.8g of solvent dimethylformamide for the first reaction, raise the temperature to 90°C, and react for 2h to obtain a mixed solution. After the reaction is over, control the temperature at 25°C, then add 30.3g of octadecyl chloride to the reacted mixed solution for the second reaction, react for 3 hours, and obtain the reaction solution, concentrate the reaction solution, and use toluene column chromatography The product was purified and separated by the method, and vacuum-dried to constant weight to obtain a permeation enhancer for fracturing, which is polyoxyethylene octadecyl amidosulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com