Icing wind tunnel heat exchanger outlet airflow temperature control system and method

A temperature control method and temperature control system technology, applied in the direction of instruments, refrigerators, refrigeration components, etc., can solve the problems of large heat load changes, temperature control lag, long flow path, etc., to change heat transfer performance and improve stability , the effect of quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

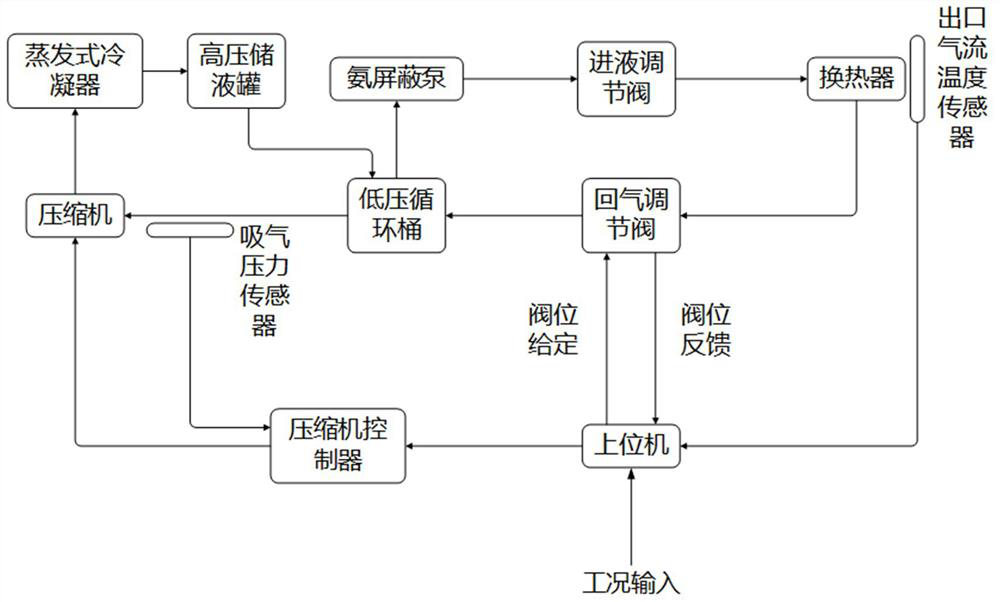

[0042] The invention provides a temperature control system for the outlet air flow of the icing wind tunnel heat exchanger, please combine with the attached figure 1 As shown, the present invention includes: compressor, suction pressure sensor, condenser (evaporative condenser), liquid storage tank (high pressure liquid storage tank), refrigerant shielded pump, heat exchanger, liquid inlet regulating valve, return air Regulating valve, temperature sensor, low-pressure circulation barrel, controller (compressor controller) and host computer; it should be explained that, as a preferred embodiment, in the present invention, ammonia is used as the refrigerant, and in other embodiments Other refrigerants can be used, Freon refrigerants (such as: R12, R11, R114, R113, R22, R13, R14, etc.), saturated hydrocarbon refrigerants (such as: methane (R50), ethane (R170), propane (R290), butane (R600), isodifluoroethane (R152a) and isobutane (R601), etc.), azeotropic refrigerants and non-aze...

Embodiment 2

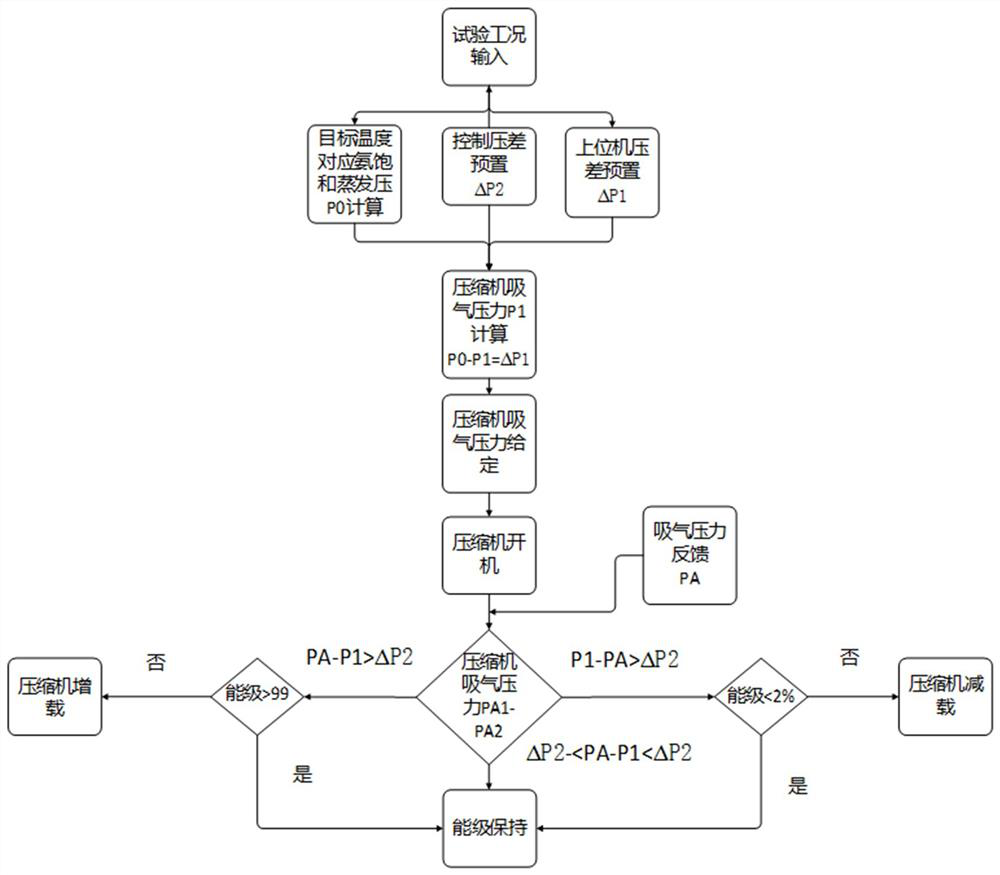

[0050] please combine figure 2 As shown, the system is roughly adjusted through the suction pressure of the compressor, and the specific steps are as follows:

[0051] Step S1: Input the test conditions, and the host computer calculates the ammonia saturation evaporation pressure P0 corresponding to the target temperature T0 of the test conditions based on the ammonia physical property fitting function (evaporation temperature - saturated evaporation pressure);

[0052] Step S2: Obtain the target suction pressure P1 of the compressor, where P1=P0+ΔP, ΔP1 is the empirical value of pressure change; in actual operation, ΔP1 is based on the pressure loss of the heat exchanger outlet pipeline and historical temperature control experience, ΔP1 In the actual experimental operation, ΔP1 is empirically set to 0.3 bar through repeated simulations; this difference can be modified in the host computer software according to the working conditions.

[0053] Step S3: Set the suction pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com