Production method of instant fresh rice noodles with long shelf life

A production method and a shelf life technology are applied in the production field of ready-to-eat long shelf life fresh rice noodles, which can solve the problems of easily damaging the taste and flavor of rice noodles, and achieve the effects of small influence on the texture and taste of rice noodles, inhibition of bacterial growth, and mellow rice flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

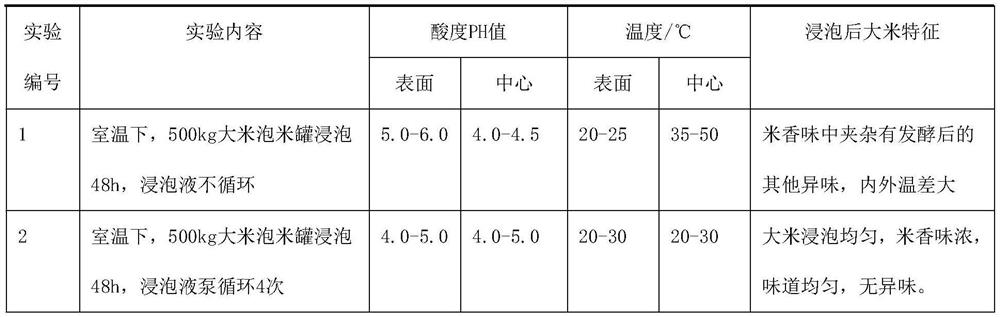

Method used

Image

Examples

Embodiment 1

[0027] Sichuan Guichao rice and Hunan Guichao rice as raw materials, each 60kg, after cleaning, natural soaking for 48h, every 12h cycle of soaking liquid; rice after water filtering, grinding powder, and noodles, double-ended spiral extrusion molding machine for two consecutive extrusion molding, a squeeze gelatinization temperature of 130 °C, gelatinization after the maturity of rice flour 75%; secondary extrusion molding temperature of 115 °C, curing degree of more than 90%, extruded rice line orifice diameter of 1.4mm.

[0028]The newly formed semi-dry rice noodles are aged for 10h under a confined space with a temperature of 25 °C and 70% humidity; the aging rice noodles are boiled in boiling water for 8 min, taken out and cooled to room temperature, the lactic acid solution with a pH value of 4.0 is soaked for 3 min, packaged into 200g by a food-grade high-temperature retort bag, sterilized at a constant temperature at 75 °C by pasteurization line for 40 min, and cooled to ...

Embodiment 2

[0031] Sichuan Guichao rice and Yunnan Guichao rice as raw materials, each 60kg, after cleaning, natural soaking for 60h, every 12h cycle of soaking liquid; rice after water filtering, grinding powder, and noodles, double-headed spiral extrusion molding machine for two consecutive extrusion molding, a squeeze gelatinization temperature of 135 °C, gelatinized rice flour curing degree of 79%; secondary extrusion molding temperature of 110 °C, curing degree of more than 90%, extruded rice line orifice diameter of 1.5mm.

[0032] The newly formed semi-dry rice noodles are placed in a closed space with a temperature of 30 °C and 80% humidity for 8h; the aging rice noodles are placed in boiling water for 10 min, taken out and cooled to room temperature, soaked in lactic acid solution with a pH of 4.5 for 3 min, packaged into 250g by food-grade high-temperature steaming bags, sterilized at a constant temperature at 80 °C by pasteurization line for 35 min, and cooled to room temperature s...

Embodiment 3

[0035] Take Hunan Guichao rice and Yunnan Guichao rice as raw materials, each 60kg, after cleaning, naturally soaked for 72h, every 12h cycle of soaking liquid; rice after water filtering, grinding powder, and noodles, double-ended spiral extrusion molding machine for two consecutive extrusion molding, a squeeze gelatinization temperature of 138 °C, gelatinization after the maturation of rice flour 82%; secondary extrusion molding temperature of 108 °C, curing degree of more than 90%, extruded rice line orifice diameter of 1.6mm.

[0036] The newly formed semi-dry rice noodles are placed in a closed space with a temperature of 35 °C and a humidity of 90% to age for 8h; the aging rice noodles are boiled in boiling water for 15 min, taken out and cooled to room temperature, the lactic acid solution with a pH of 5.0 is soaked for 3 min, packaged into 300g by food-grade high-temperature retort bags, sterilized at a constant temperature at 85 °C by pasteurization line for 40 min, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com