Method for improving fragrance of chicken soup through heat preservation pretreatment-medium pressure cooking

A technology of heat preservation treatment and chicken soup, which is applied in the fields of food processing technology and food chemistry, can solve the problems of ineffective formation of characteristic aroma substances, deterioration of broth flavor quality, and single boosting procedure, achieving significant application and promotion value, suitable for intestines Poor tract absorption function and high absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

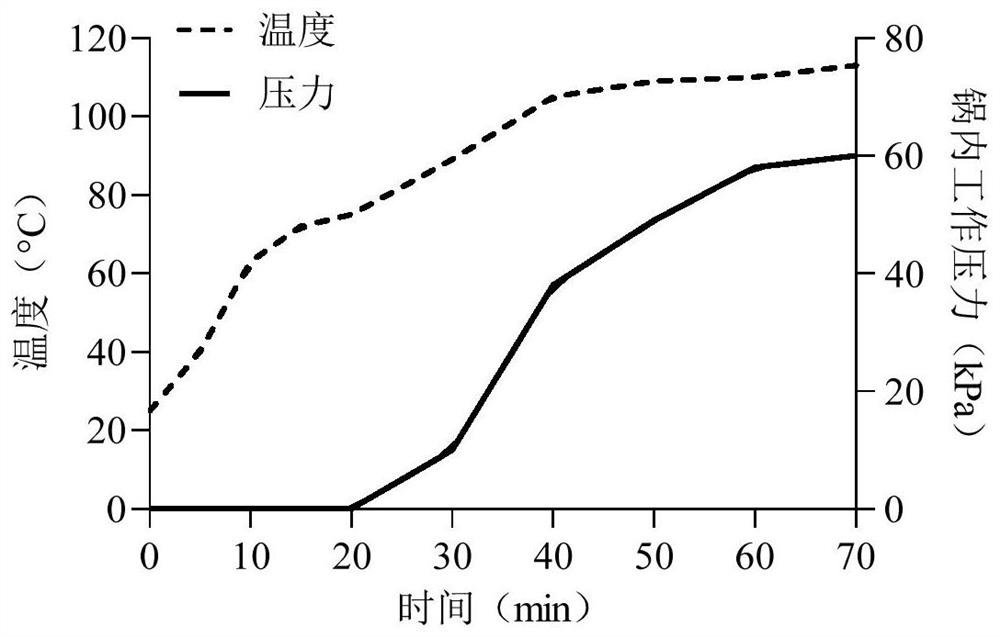

[0032] Rinse the fresh chicken breast with water, cut the chicken into 4cm square pieces of uniform size, mix 250g of meat pieces with 1000g of water and put them in an electric pressure cooker for heating. After the temperature rises to 75°C, keep it warm for 30 minutes, and then reduce the working pressure in the pot. Be raised to 60kPa, keep the pressure for 30min, and finally reduce the pressure in the pot to normal pressure to obtain the chicken soup with improved aroma.

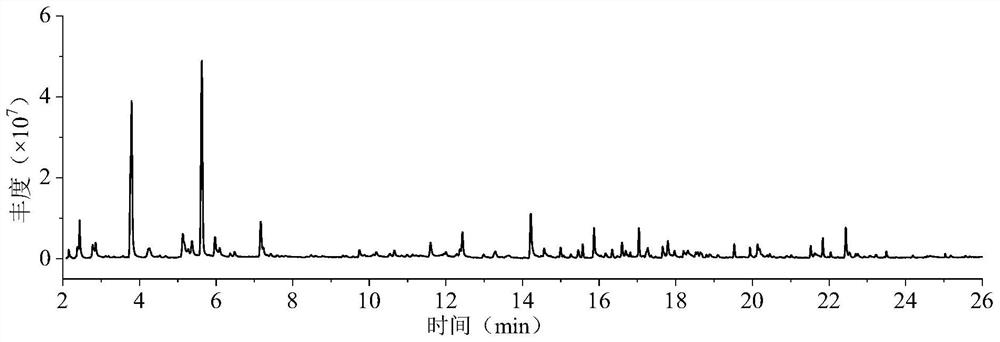

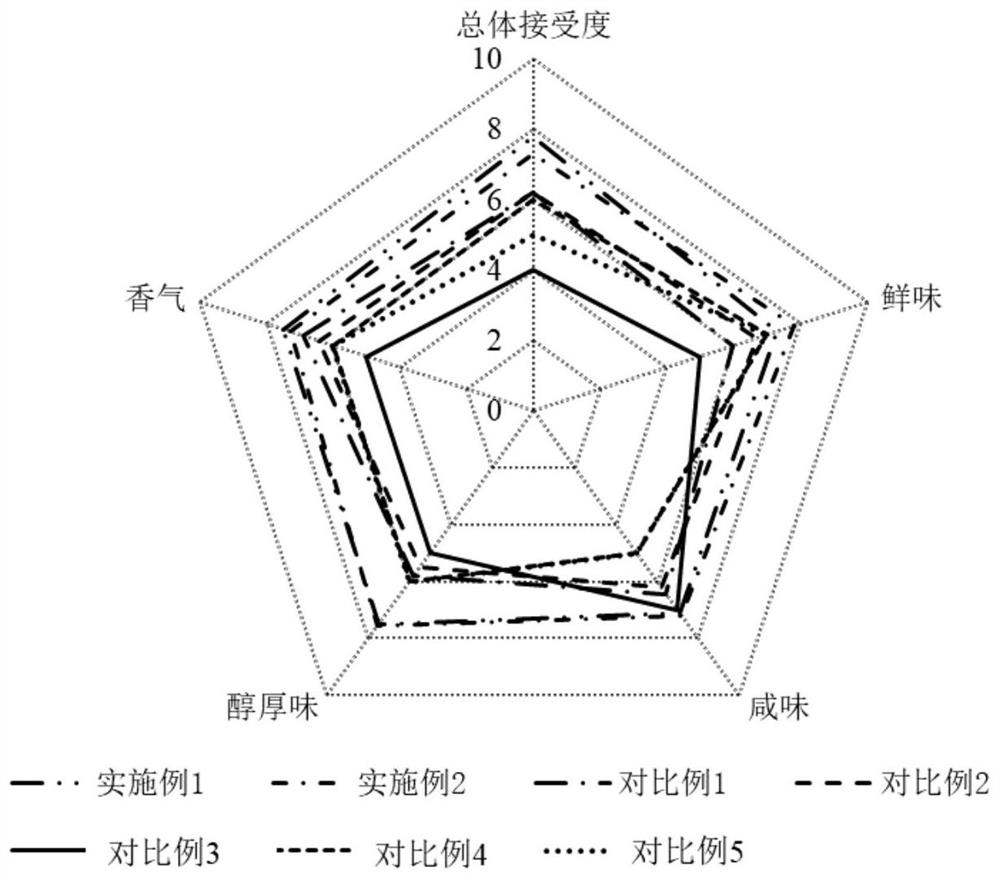

[0033] The type and concentration of volatile flavor substances in chicken soup were analyzed by solid phase microextraction-gas chromatography-mass spectrometry, and the chromatographic results were as follows: figure 2Shown, wherein the main volatile flavor substances and concentrations are shown in Table 1. Conduct sensory evaluation of chicken soup, the scores of overall acceptance, freshness, saltiness, mellow taste and aroma of chicken soup are as follows: image 3 shown.

Embodiment 2

[0035] Rinse the fresh chicken breast with water, cut the chicken into 4cm square pieces of uniform size, mix 250g of meat pieces with 1000g of water and put them in an electric pressure cooker for heating. After the temperature rises to 75°C, keep it warm for 30 minutes, and then reduce the working pressure in the pot. Be raised to 60kPa, keep the pressure for 20min, and finally reduce the pressure in the pot to normal pressure to obtain the chicken soup with improved aroma.

[0036] The type and concentration of volatile flavor substances in chicken soup were analyzed by solid phase microextraction-gas chromatography-mass spectrometry, and the chromatographic results were as follows: Figure 4 Shown, wherein the main volatile flavor substances and concentrations are shown in Table 1. Conduct sensory evaluation of chicken soup, the scores of overall acceptance, freshness, saltiness, mellow taste and aroma of chicken soup are as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com