Disc tube type vacuum multi-effect membrane distillation assembly and system

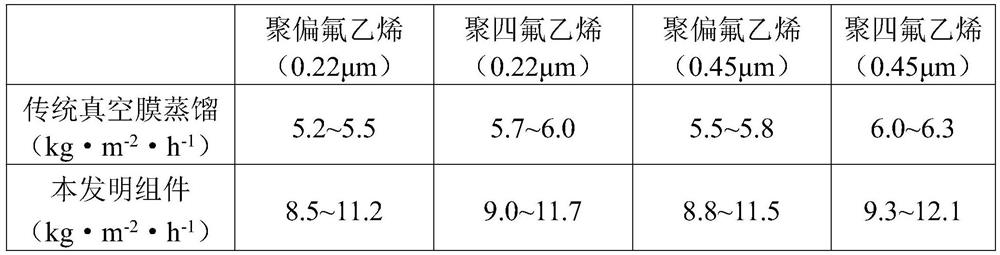

A multi-effect membrane distillation and disc tube technology, applied in the field of membrane distillation, can solve the problems of high equipment investment and operation costs, special system materials, and harsh operating conditions, so as to reduce equipment costs, increase membrane distillation flux, The effect of high running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

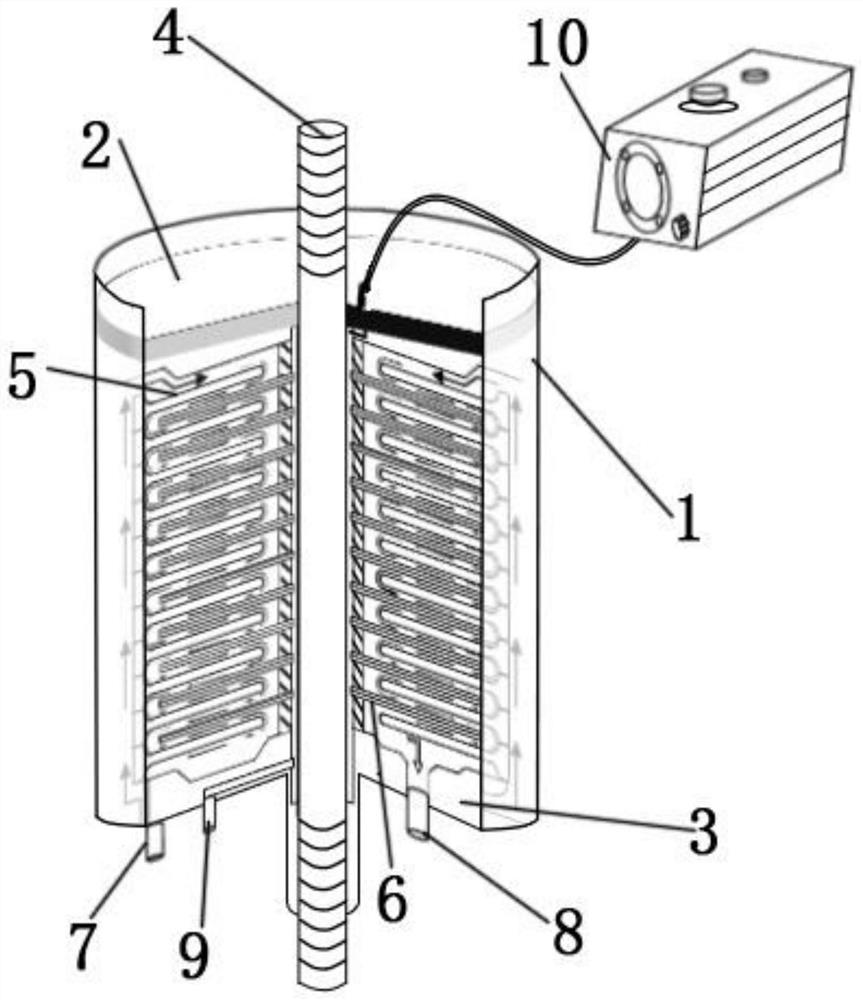

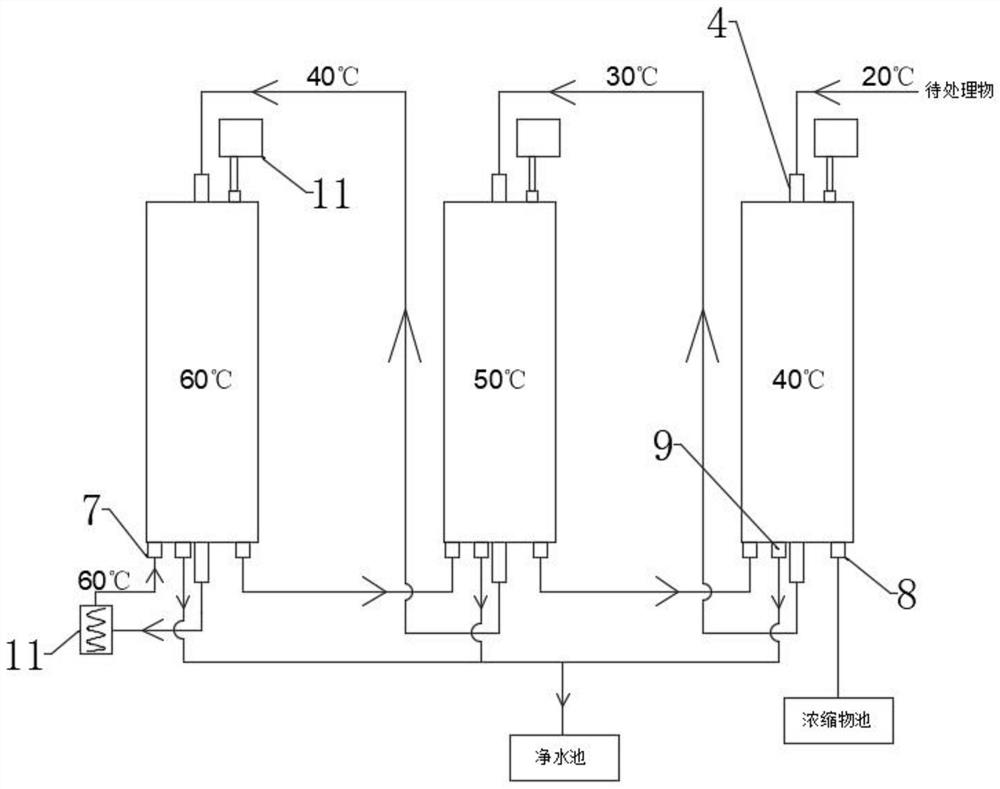

[0024] like figure 1 As shown, a disc-type vacuum multi-effect membrane distillation assembly includes a disc-type component, and the disc-type component includes a shell 1, and an upper flange 2 and a lower flange are respectively arranged at both ends of the shell 1. The blue plate 3, the upper flange 2 and the lower flange 3 are fixed by the center tie rod 4, the center tie rod 4 is a hollow structure, and the cavity of the center tie rod 4 is used as a cooling channel for passing into the cooling Medium, to speed up the condensation speed of steam, a deflector plate 5 and a disc-type diaphragm 6 are arranged inside the shell 1, and the film on the disc-type diaphragm 6 is a pervaporation film or a distillation film. The upper flange 2 or the lower flange 3 are provided with an inlet 7 for a substance to be treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com