Master-slave cooperative positioning and clamping device for realizing near-zero sliding of high-speed rail gear shaft

A technology of co-location and clamping device, applied in the direction of gear teeth manufacturing device, components with teeth, belt/chain/gear, etc., can solve impact and sliding, high shape accuracy and surface quality, machining track deviation, etc. problems, achieve the effects of suppressing the impact and sliding of the gear shaft, high shape accuracy and surface quality, and reducing machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

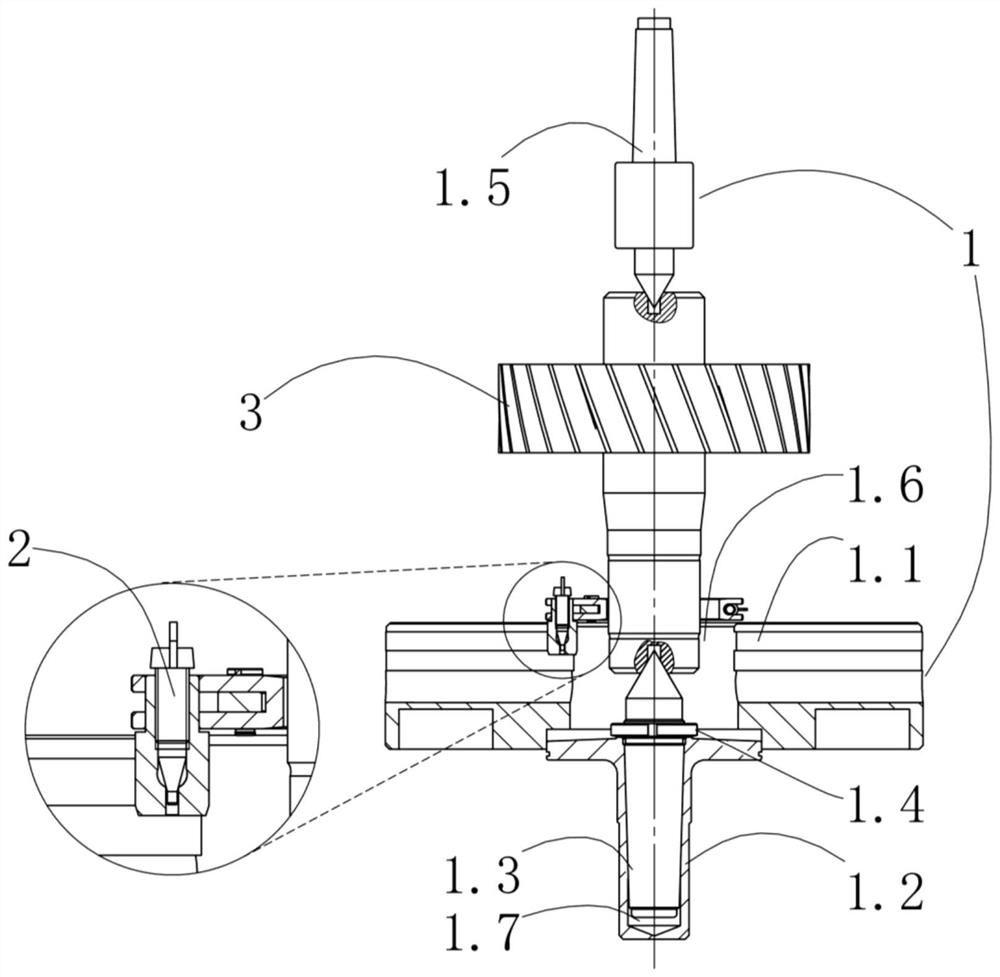

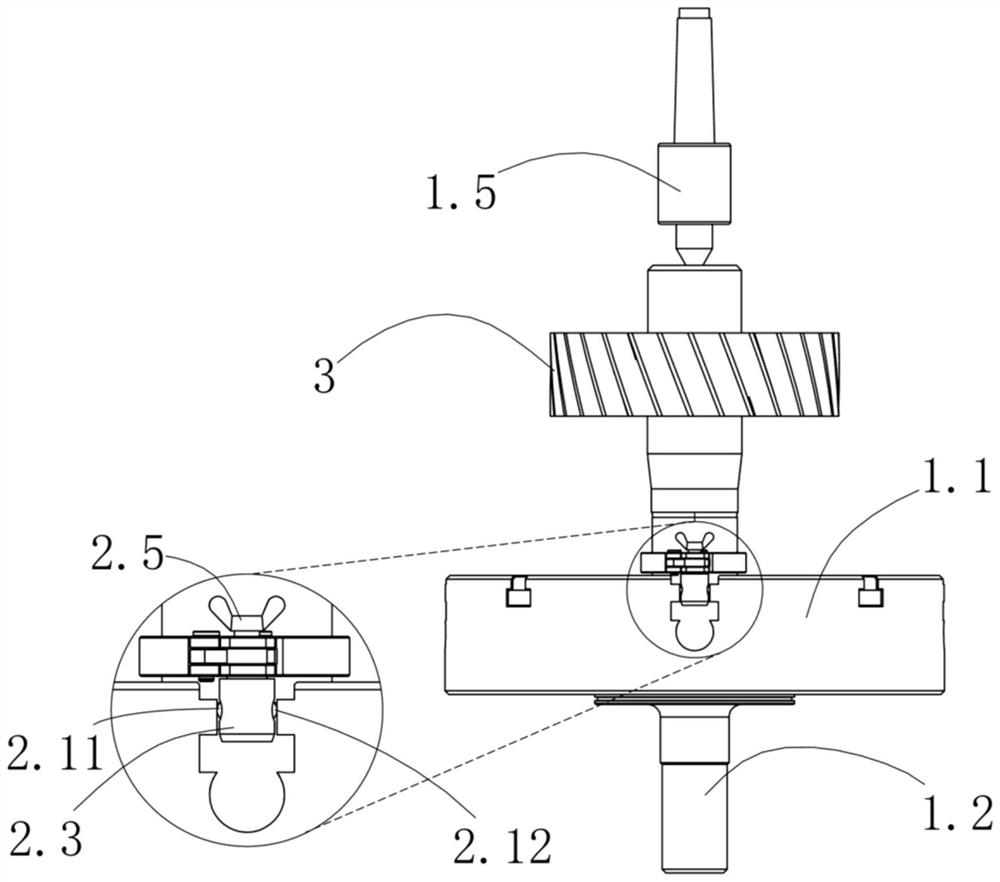

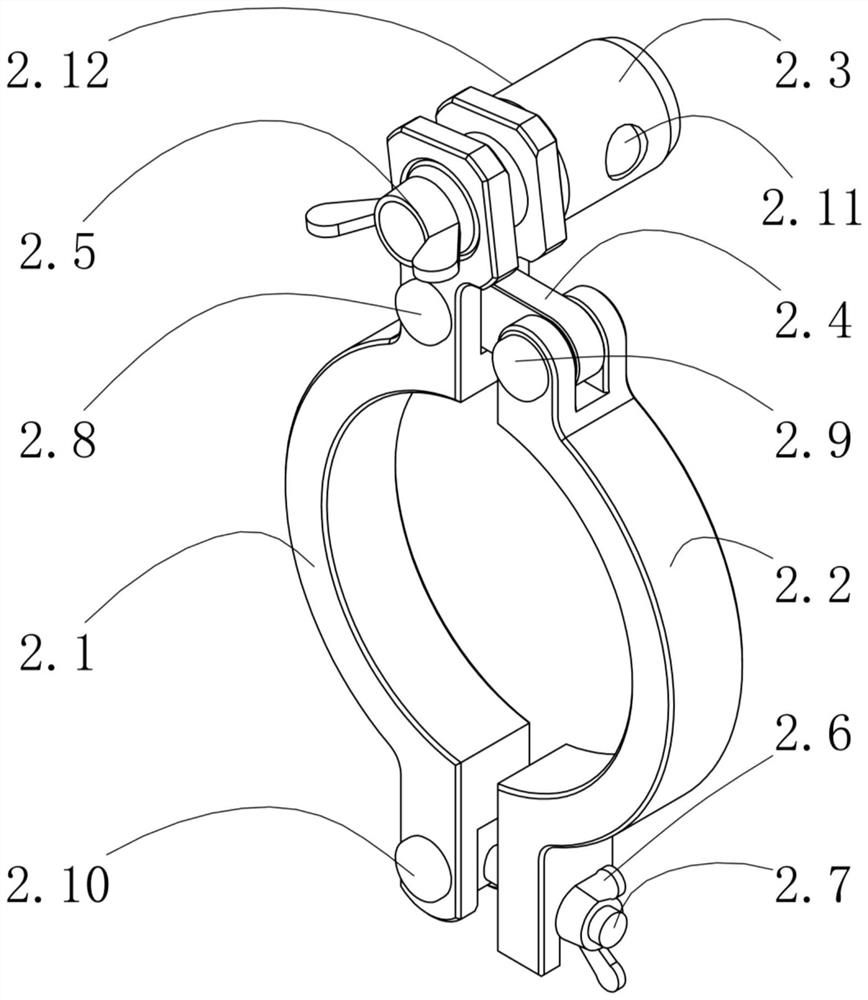

[0034] Such as Figure 1 to Figure 5 As shown, the present invention provides a master-slave cooperative positioning clamping device that realizes near-zero sliding of the high-speed rail gear shaft, including a master positioning center assembly 1 and a slave positioning journal chuck assembly 2, and the master positioning center assembly 1 is used to realize the gear The axial positioning and radial positioning of the shaft 3, wherein the chuck 1.1, the chuck positioning plate 1.2, the lower center 1.3 and the round nut 1.4 are clamp bodies, and the chuck assembly 2 of the positioning journal is used to realize the circumferential positioning of the gear shaft 3, One end clamps the gear shaft 3, and the other end is clamped and fixed with the chuck 1.1. Through the synergistic effect of the main positioning tip assembly 1 and the secondary positioning journal chuck assembly 2, the six degrees of freedom of the gear shaft 3 are limited, that is, along the x The degree of free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com