Graphite vacuum double-sided floating pressing forming system

A press forming and vacuum technology, which is applied in the direction of material forming presses, stamping machines, presses, etc., can solve the problems of low product yield, long production cycle, and difficulty in exerting the performance of special graphite technology products, and achieve product yield. High, shortened production cycle, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

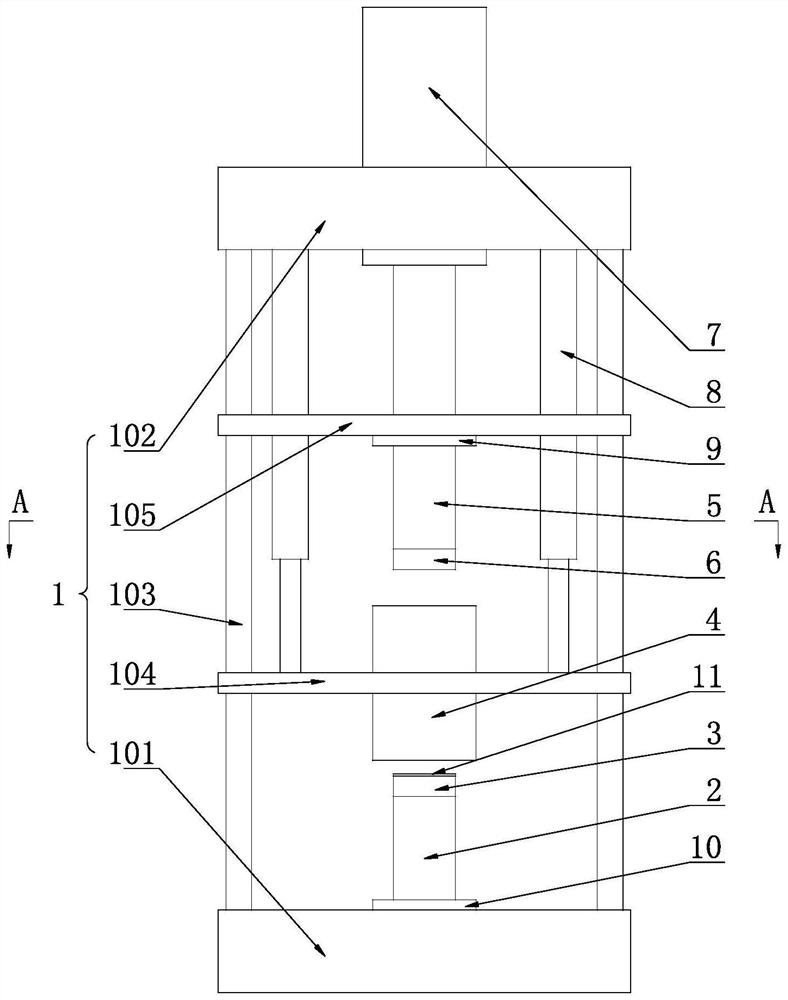

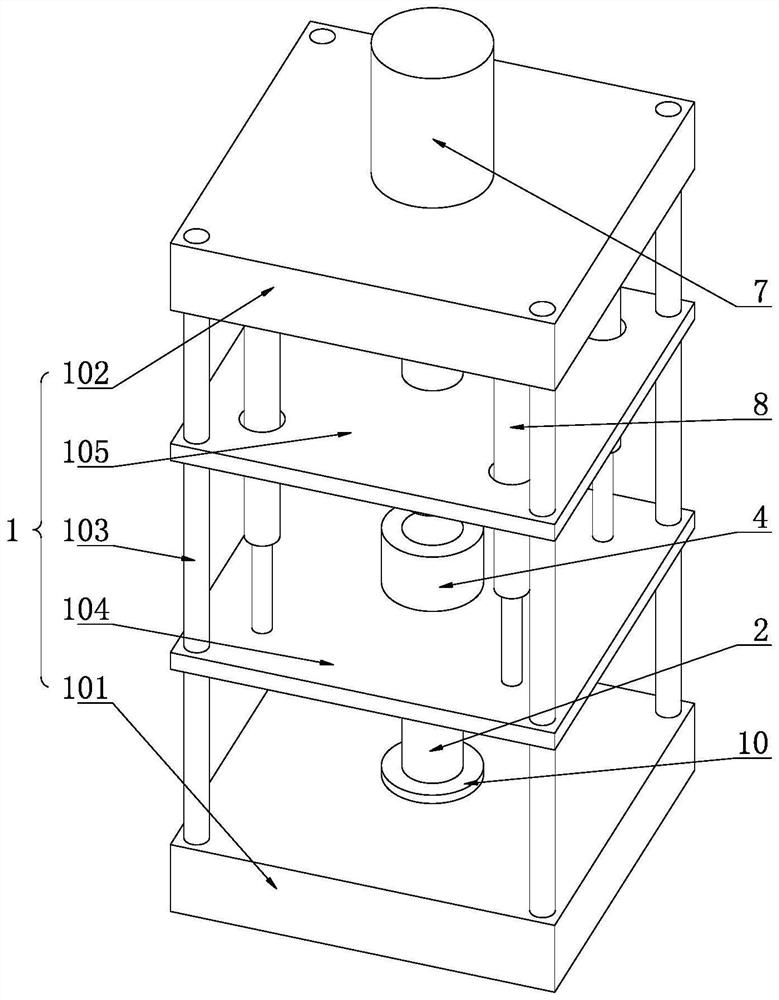

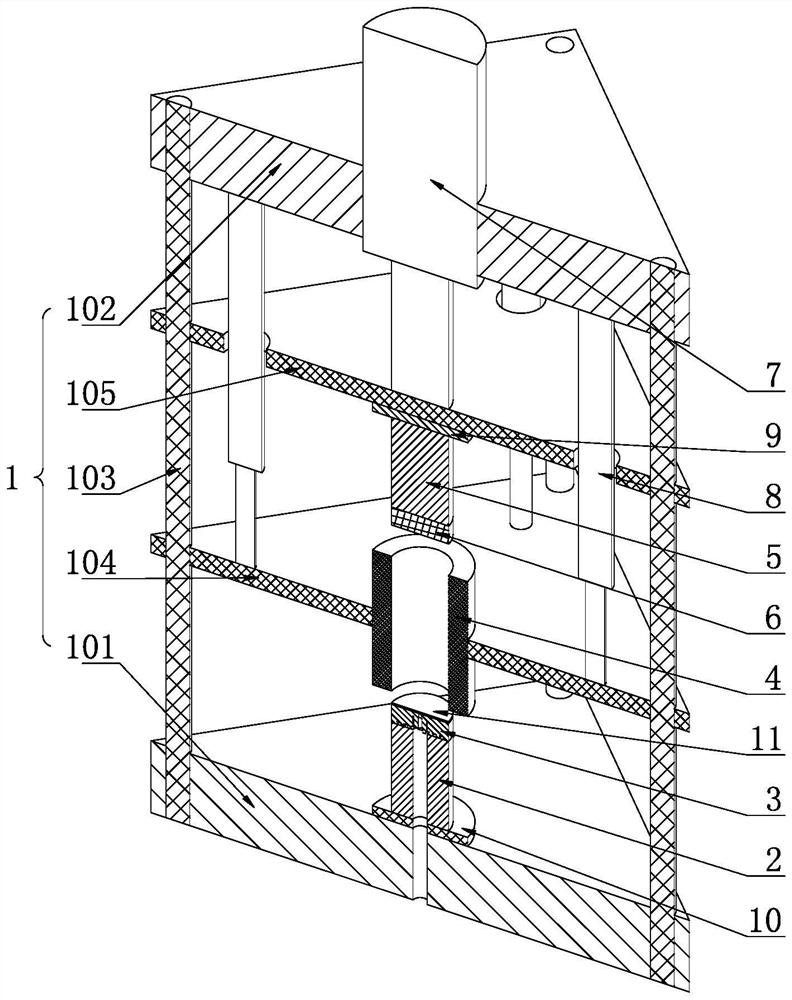

[0033] Such as Figure 1-6 Shown, a kind of graphite vacuum double-sided floating press-forming system, the press-forming system includes pressing frame 1, lower pressing bar 2, lower pressing die 3, die sleeve 4, upper pressing bar 5 and upper pressing die 6, lower pressing bar 2. Vertically and fixedly arranged at the lower part of the pressing frame 1, the lower pressing die 3 is arranged at the upper end of the lower pressing rod 2, the mold cover 4 is vertically slidably arranged in the middle of the pressing frame 1, the middle part of the mold cover 4 is provided with a vertical mold cavity, and the upper pressing rod 5. The vertical sliding is arranged on the upper part of the pressing frame 1, and the upper pressing die 6 is arranged at the lower end of the upper pressing rod 5;

[0034] The mold cavity of the mold case 4 is set corresponding to the lower pressure rod 2 and the upper pressure rod 5; when the lower pressure rod 2 is located in the mold cavity of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com