Auxiliary anode and preparation method and application thereof

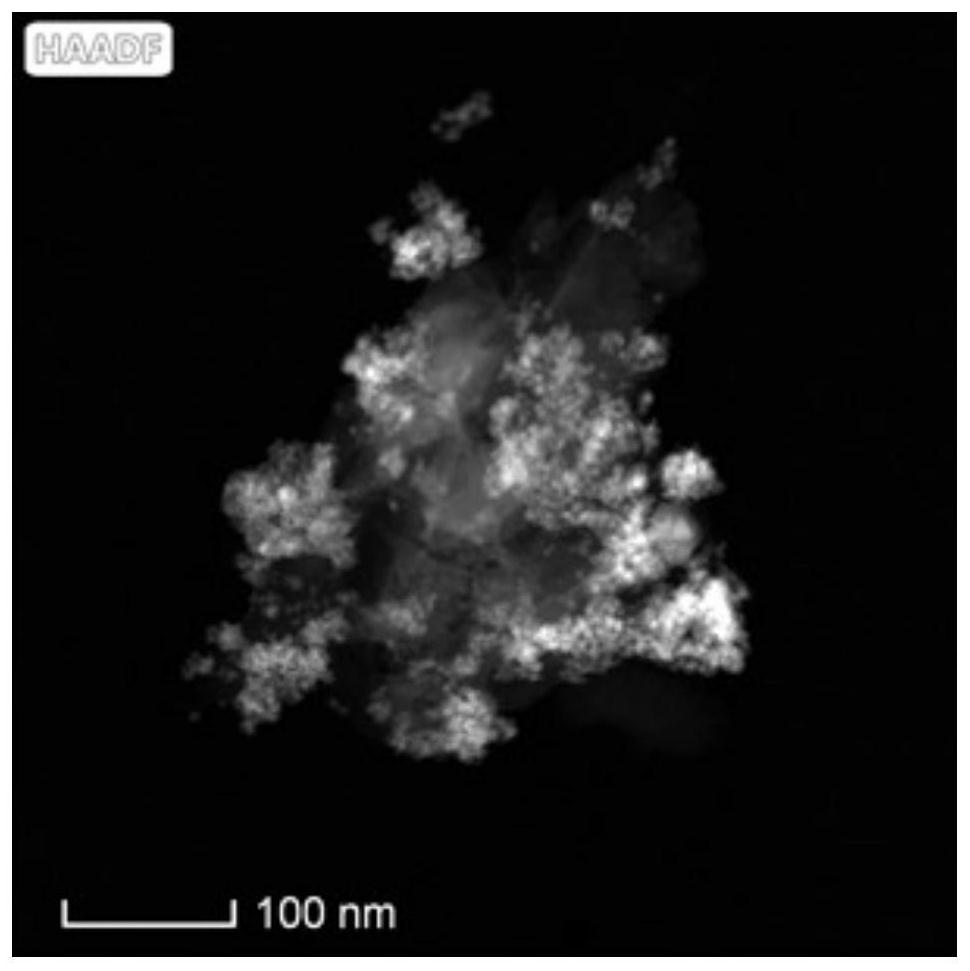

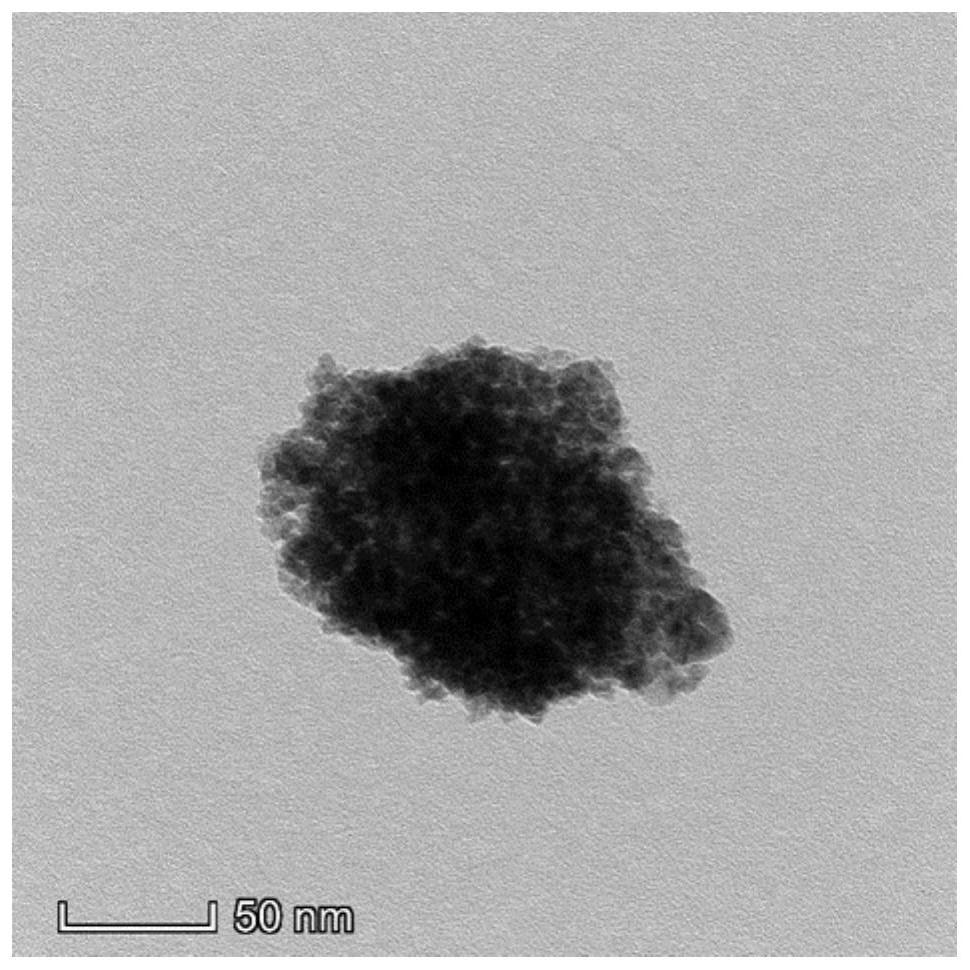

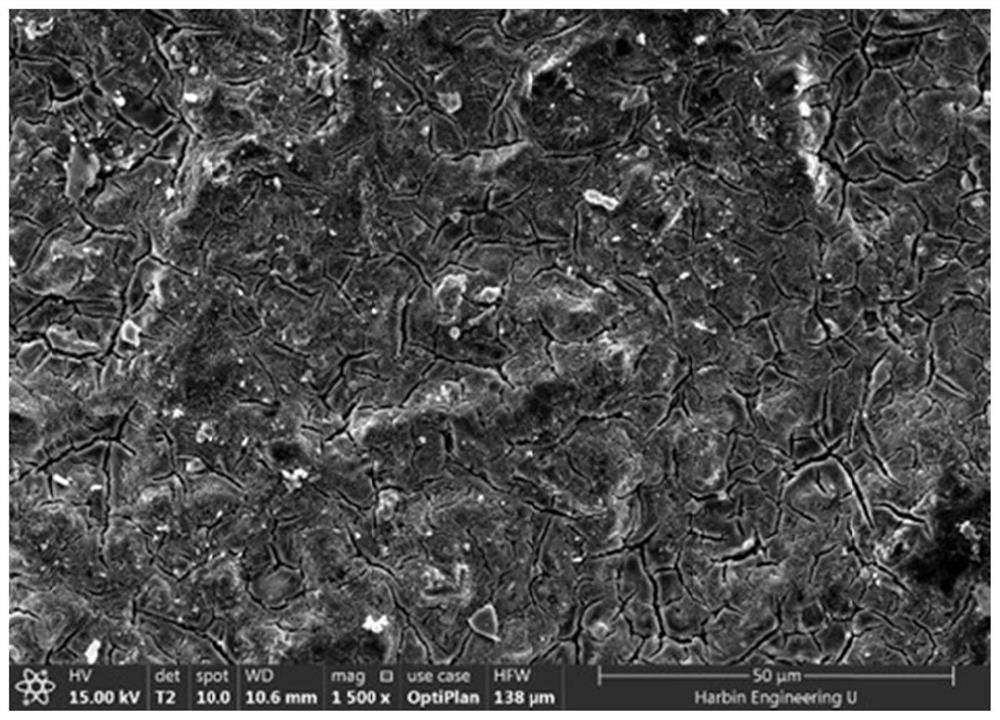

A technology of auxiliary anode and coating solution, applied in the field of auxiliary anode and its preparation, can solve the problems of easy deterioration of auxiliary anode performance, reduced gas evolution activity, poor stability, etc., so as to improve electrochemical performance, reduce dosage, and reduce cracks. The effect of size and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The preparation method of the auxiliary anode of embodiment 1, concrete preparation process is:

[0091] 1) Substrate pretreatment: Use a sandblasting machine to perform all-round surface peeling treatment on the titanium substrate (titanium plate) of 2cm×2cm×0.2cm to remove the oxide skin on the surface until the titanium substrate reveals a metallic luster, and use a flow deionization Wash with water; then put the titanium substrate into the lye solution, and heat it at 100°C for a certain period of time to remove the oil on the surface of the titanium substrate; then put the titanium substrate into the alkaline solution and heat it at 100°C for 2 hours for acid etching; After the acid-etched titanium substrate was washed alternately with deionized water and absolute ethanol for 3 times, a rough titanium substrate with a pitted surface was obtained, and the pretreated titanium substrate was dried and stored in absolute ethanol;

[0092] 2) Preparation of anode coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com