Composite hydrogel and preparation method thereof

A technology of composite hydrogel and mixed solution, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, and aerosol delivery, etc., and can solve problems such as unsatisfactory overall healing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] The present invention also provides a method for preparing the composite hydrogel described above, comprising the following steps:

[0086] The loaded MOFs are dissolved in the solvent medium, and the obtained mixed solution is mixed with aldylated hyaluronic acid (HA-CHO) having the structure shown in formula (I) and hyaluronic acid-hexadiene having the structure shown in formula (II) Acid dihydrazide derivatives (HA-ADH) were mixed to obtain a composite hydrogel.

[0087] In some embodiments of the present invention, the preparation method of the composite hydrogel comprises the following steps:

[0088] A) dissolving the loaded MOFs in a solvent medium to obtain a loaded MOFs solution;

[0089] B) mixing the partly loaded MOFs solution with the aldylated hyaluronic acid (HA-CHO) having the structure shown in formula (I), to obtain the HA-CHO mixed solution;

[0090] Mix the remaining loaded MOFs solution with the hyaluronic acid-adipate dihydrazide derivative (HA-A...

Embodiment 1

[0129] Take 2.0g (0.005mol) of sodium hyaluronate (10% oxidation degree) with a number average molecular weight of 40000 and dissolve it in 200mL of deionized water to obtain a sodium hyaluronate solution; another 1.1276g (0.005mol) of sodium periodate Dissolve in 20 mL of deionized water to obtain a sodium periodate solution; then add the sodium periodate solution dropwise into the sodium hyaluronate solution, and react at 20° C. for 5 hours under the condition of avoiding light. Add 6mL of ethylene glycol and continue to stir in the dark for 30min to terminate the oxidation reaction, add the reacted reaction solution into a dialysis bag with a molecular weight cut-off of 3500, dialyze and purify in deionized water, and further lyophilize to obtain Aldylated hyaluronic acid (HA-CHO) of the structure shown, wherein, m=10, n=100.

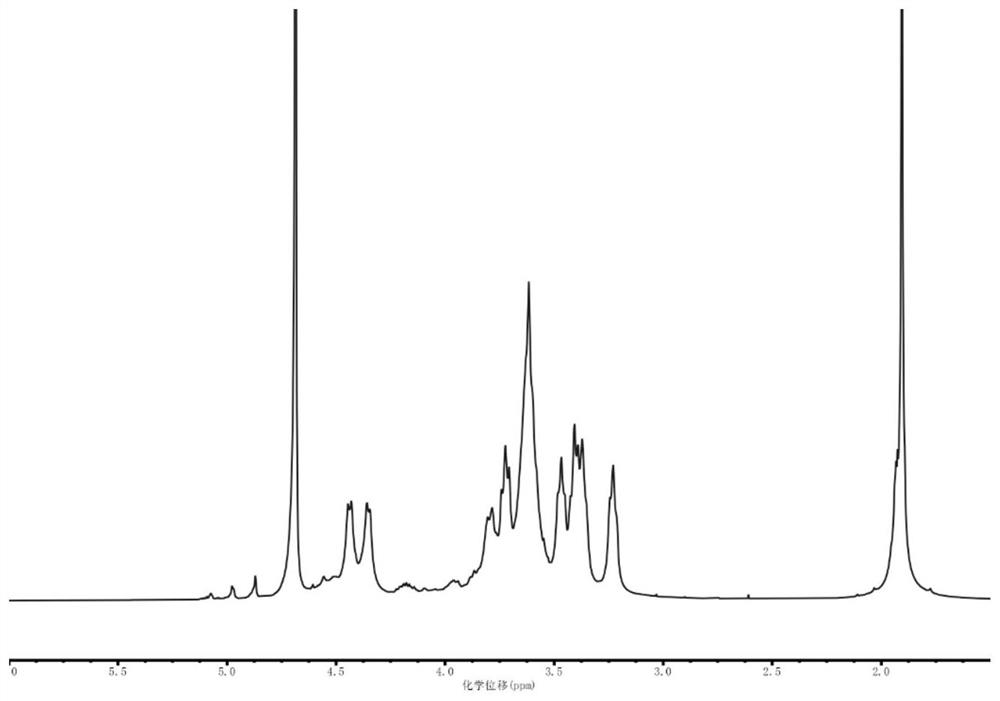

[0130] The obtained HA-CHO was analyzed by proton nuclear magnetic spectrum data, and the results were as follows: figure 1 shown. figure 1 It is ...

Embodiment 2

[0132] Take 0.6g (0.0015mol) of sodium hyaluronate (40% oxidation degree) with a number average molecular weight of 24000 and dissolve it in 60mL of deionized water to obtain a sodium hyaluronate solution; another 0.3388g (0.0015mol) of sodium periodate Dissolve in 6 mL of deionized water to obtain a sodium periodate solution; then add the sodium periodate solution dropwise into the sodium hyaluronate solution, and react at 25° C. for 5 hours under the condition of avoiding light. Add 0.6mL of ethylene glycol and continue to stir in the dark for 30min to terminate the oxidation reaction. The reaction solution after the reaction is added into a dialysis bag with a molecular weight cut-off of 3500, purified by dialysis in deionized water, and further freeze-dried to obtain ) the formylated hyaluronic acid (HA-CHO) of the structure shown, wherein, m=24, n=60.

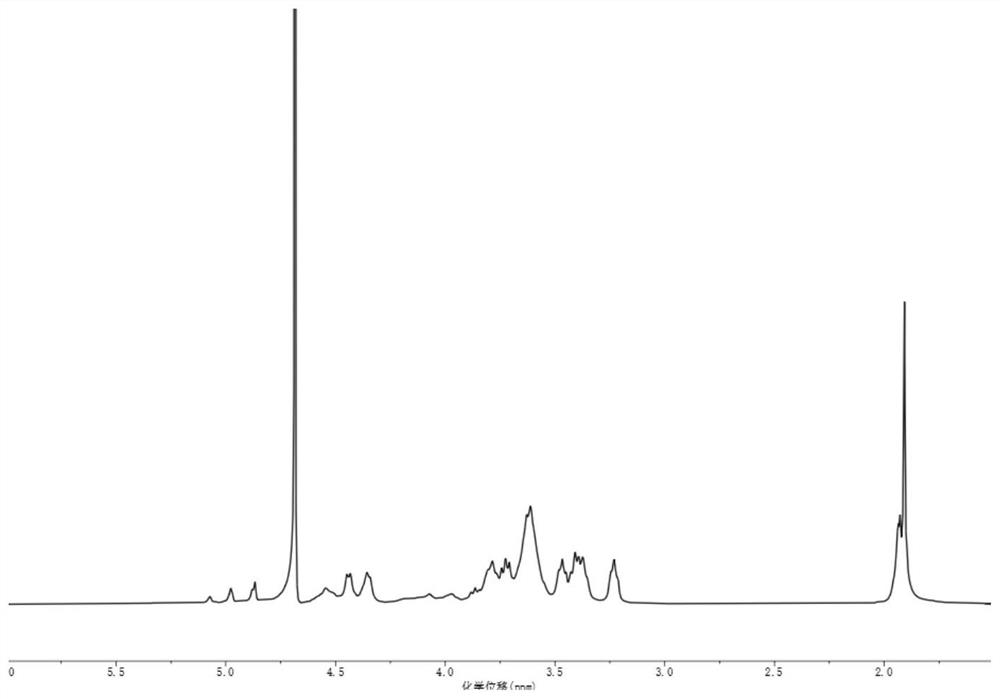

[0133] The obtained HA-CHO was analyzed by proton nuclear magnetic spectrum data, and the results were as follows: fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com