Mixed powder brazing filler metal, preparation method thereof, welding interlayer and welding method

A technology of mixing powder and welding method, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem of lack of fiber material, etc., and achieve the effect of high weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Second, embodiments of the present invention provides a method for preparing the above-described mixed powder filler, comprising: mixing the first nickel-based alloy powder and the second nickel-based alloy powder according to the proportion.

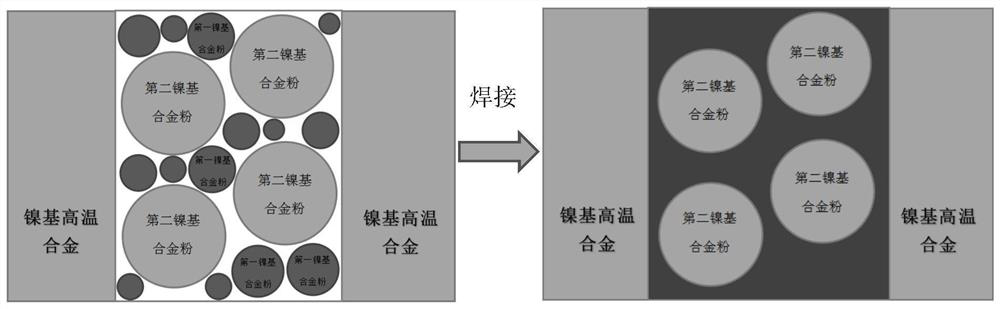

[0039] Third, embodiments of the present invention provides a welding intermediate layer, prepared by the above-described mixed powder filler. Specifically, the mixed powder fiber is placed between two materials to be welded, and then continues to weld, and then forms a welding intermediate layer.

[0040] Fourth, embodiments of the present invention provides a welding method, comprising: the above-described mixed powder filler is disposed between the butt welding surfaces of the nickel-based superalloy to be welded, and then welded. Among them, the welding conditions include: temperature of 1180-1270 ° C, pressure of 0.1-10MPa, holding time of 0.5-8 hours. The use of the above welding conditions can ensure the smooth progress of wel...

Embodiment 1

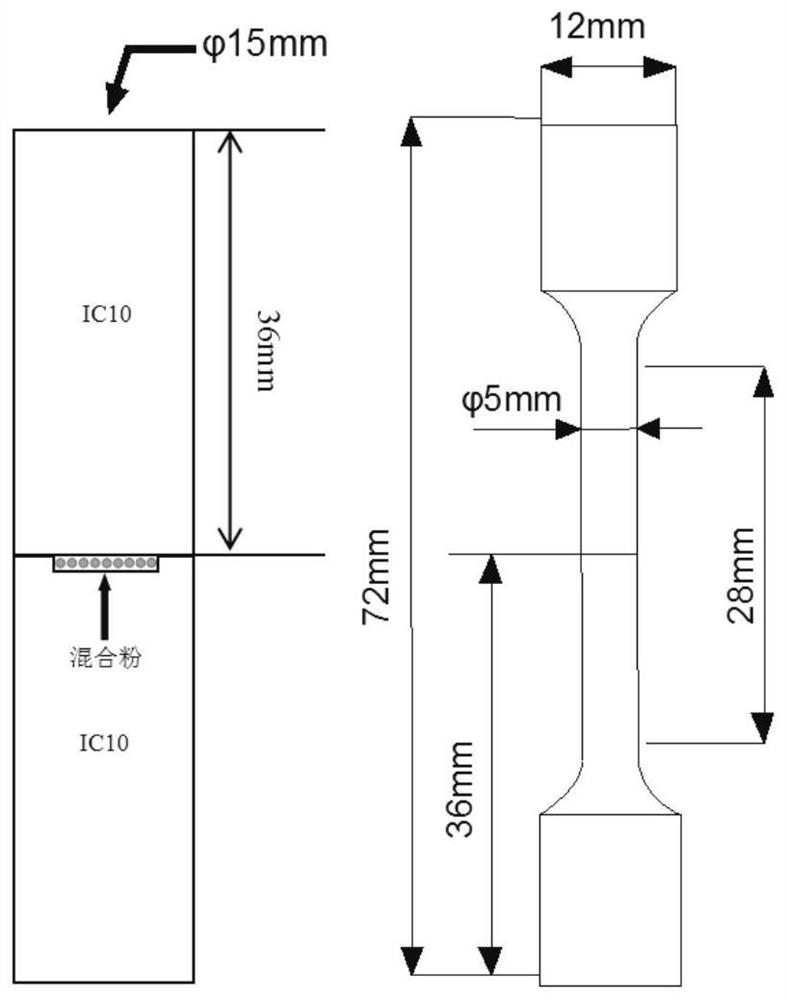

[0043]Embodiments of the present invention provides a mixed powder filler comprising a 70% first nickel-based intermediate layer alloy powder and 30% second nickel-based alloy powder. Among them, the chemical composition of the first nickel-based alloy powder: C0.1%, Cr12.5%, Co6.8%, Mo0.9%, W4.5%, Al2.9%, Ti4.7%, Nb1.2%, Ta3.4%, Re2.9%, B1.6%, V1.2%, Ru1.5%, Si0.3% and the residual amount is nickel, the particle size of the first nickel-based alloy is 400 mesh, the particle size of the second nickel-based alloy is 100 mesh, the composition of the second nickel-based alloy is consistent with the composition of nickel-based superalloy, and the nickel-based superalloy is IC10 directional solidification superalloy bar, purchased from the Institute of Metal Research of the Chinese Academy of Sciences, the first nickel-based alloy powder and the second nickel-based alloy powder are prepared by aerosol method.

[0044] The present embodiment provides a welding method comprising:

[004...

Embodiment 2

[0050] Embodiments of the present invention provides a mixed powder brazing material comprising 60% first nickel-based alloy powder and 40% second nickel-based alloy powder. Among them, the chemical composition of the first nickel-based alloy powder: C0.1%, Cr12.4%, Co6.8%, Mo0.9%, W4.5%, Al2.9%, Ti4.7%, Nb1.2%, Ta3.4%, Re3.0%, B1.7%, V1.2%, Ru2.4%, Si0.3% and the margin is nickel, the particle size of the first nickel-based alloy is 500 mesh, the particle size of the second nickel-based alloy is 150 mesh, the composition of the second nickel-based alloy is consistent with the composition of nickel-based superalloy, and the nickel-based superalloy is IC10 directional solidification superalloy bar, purchased from the Institute of Metal Research, Chinese Academy of Sciences.

[0051] The present embodiment provides a welding method comprising: the cleaning of the IC10 bar to be welded in the fixture, the welding bar sandwiched between the above-described mixed powder fiber compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com