Outer rotor hub motor driven automobile tire online self-inflating and deflating system

A technology for in-wheel motors and automobile tires, applied in electric vehicles, electric braking systems, motors, etc., can solve the problems of failure to achieve integration and low degree of chassis integration, achieve improved passability and safety, and simple structure , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

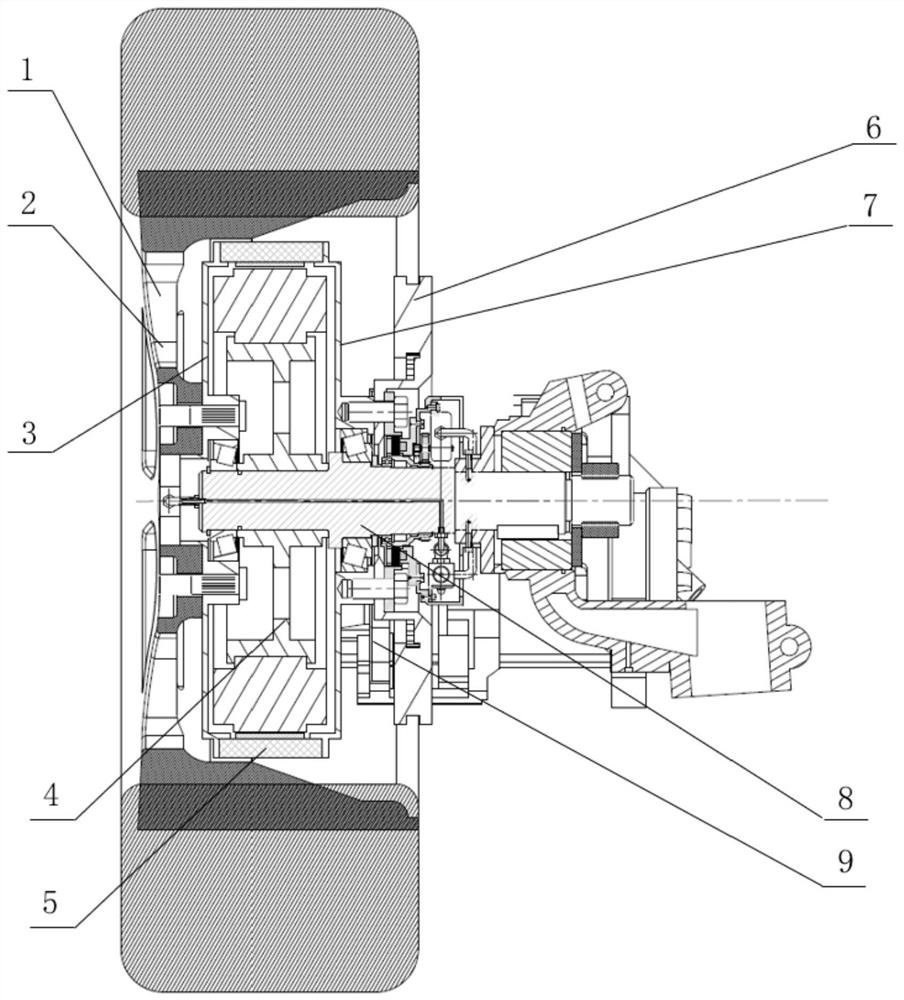

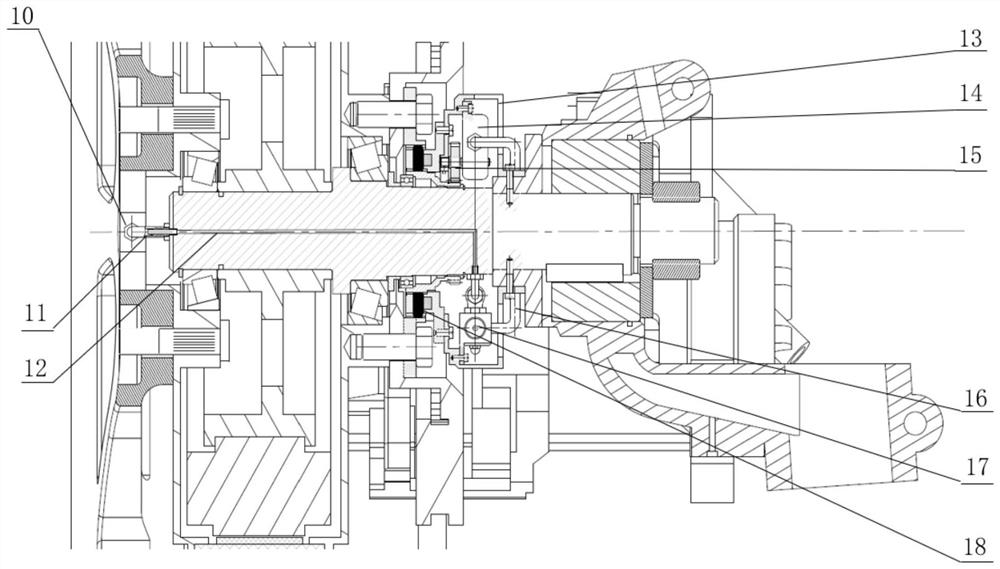

[0045] see figure 1 and figure 2 As shown, the on-line self-inflation and deflation system for automobile tires driven by an outer rotor hub motor of the present invention includes a rim (1), a drive motor, an inflation and deflation unit, and a braking unit;

[0046] The rim (1) is used to fix and support automobile tires, and its central inner hole is different from the way traditional automobiles use a through hole to place a decorative plastic cover, but adopts a non-through hole design to form a closed space;

[0047] The drive motor is an outer rotor hub motor, which is coaxially arranged in the rim (1), and its outer side is connected to drive the rim (1) and the tire to rotate, thereby generating ground driving force to drive the car; of course, the hub motor It can also generate electromagnetic braking force to force the wheel to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com