Composite hydrogen storage material containing LiNH2 and Mg and preparation method thereof

A hydrogen storage material, hydrogen technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of difficult to control the relative content of crystal substitution elements, unfavorable production and application, large amount of energy, etc., to achieve uniform size and shape. Appearance rules, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a LiNH-containing 2 and the preparation method of the composite hydrogen storage material of Mg, in a preferred scheme, mainly realize according to the following steps:

[0042] (1) Lithium amide (LiNH 2 ) and magnesium (Mg) powder are mixed evenly at a molar ratio of 1:1, and put into a ball mill;

[0043] (2) Adopt the mechanical alloying method, use the mechanical ball milling method, ball mill on the ball mill, the weight ratio of the ball and the mixed raw material is 29:1, the ball milling time is 6h, the ball milling speed is 400rpm, and the LiNH-containing 2 and Mg composite hydrogen storage materials.

[0044] The ball mill mentioned above is a planetary ball mill or a vibration ball mill.

[0045] In a preferred version of the present invention, the main phase obtained by the method is LiNH 2 and Mg, where LiNH 2 The molar ratio to Mg is 1:1, the particle size is <1 micron, and the hydrogen desorption capacity reaches 4.1wt%.

[00...

Embodiment 1

[0049] The raw material is commercially available lithium amide powder (LiNH 2 , purity 95%) and magnesium powder (Mg, purity 99%), both according to pure LiNH 2 Mix it with pure Mg in a molar ratio of 1:1 and then perform dry ball milling. Take 3g of the mixed raw material and put it into a 250ml ball mill tank (the atmosphere in the tank is 1 atm of argon gas). The ratio of balls to mixed raw material is 29:1. The ball milling speed is 400rpm, the ball milling time is 6h, and the ball milling process is rested for 3 minutes every 10 minutes to prevent the ball milling tank from overheating during the ball milling process. Sample LiNH 2 Decomposition occurs, and after ball milling, LiNH-containing 2 and Mg composite hydrogen storage materials.

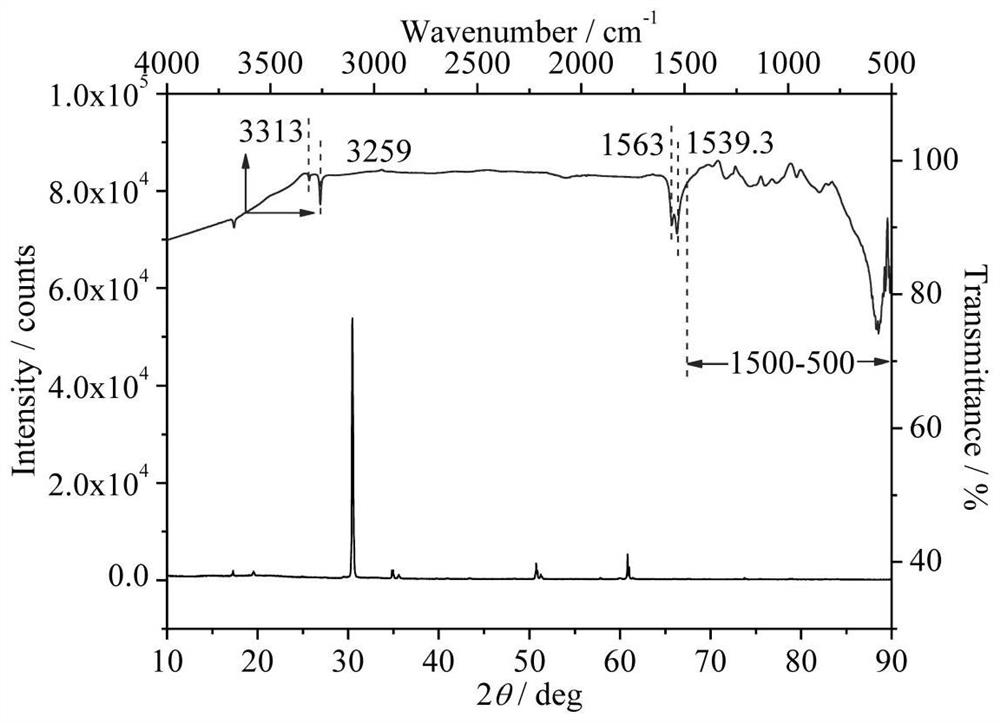

[0050] figure 1 For the lithium amide (LiNH3) purchased in embodiment 1 2 ) XRD and FTIR detection spectrum.

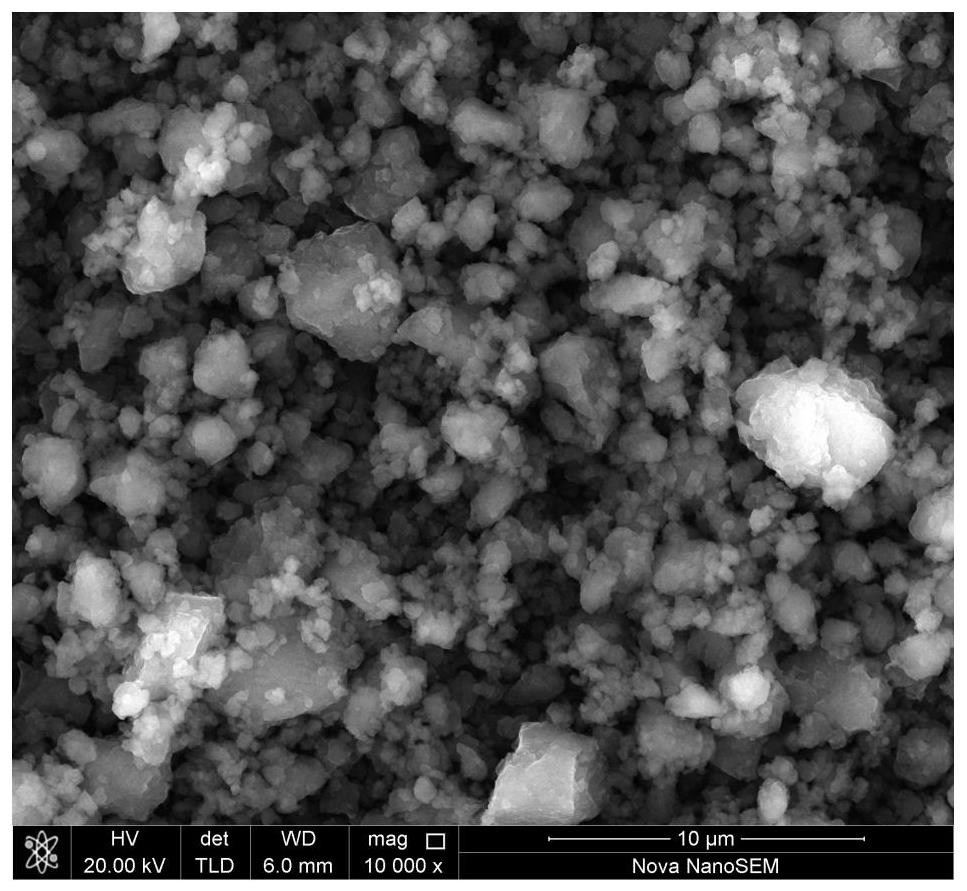

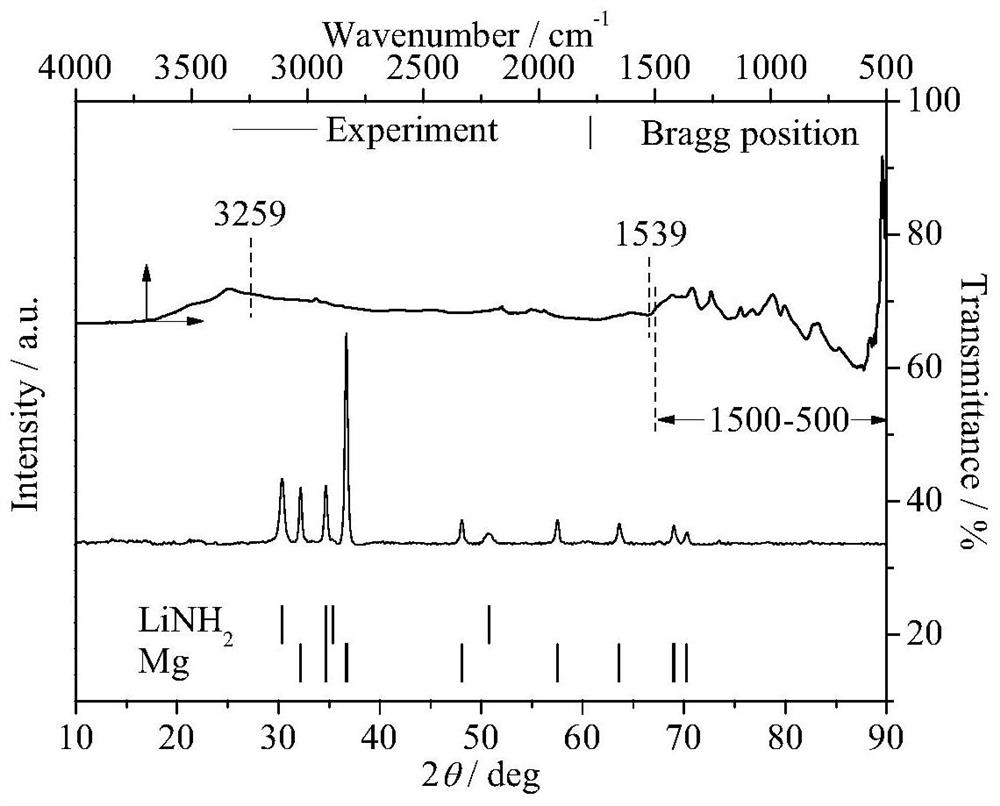

[0051] figure 2 For example 1 lithium amide (LiNH 2 ) and magnesium (Mg) at a molar ratio of 1:1 were mixed and bal...

Embodiment 2

[0059] The raw material is commercially available lithium amide powder (LiNH 2 , purity 95%) and magnesium powder (Mg, purity 99%), both according to pure LiNH 2 After uniformly mixing with pure Mg in a molar ratio of 2:1, carry out dry ball milling, take 3g of mixed raw materials, put them into a 250ml ball mill tank (the atmosphere in the tank is 1atm argon), the ratio of balls and mixed raw materials is 29:1, The ball milling speed is 400rpm, the ball milling time is 6h, and the ball milling process is rested for 3 minutes every 10 minutes to prevent the ball milling tank from overheating during the ball milling process. Sample LiNH 2 Decomposition occurs, and after ball milling, LiNH-containing 2 and Mg composite hydrogen storage materials.

[0060] In this implementation, LiNH-containing 2 The TPD-MS curve of the composite hydrogen storage material of Mg is as Figure 7 (c) shown. Depend on Figure 7 (c) It can be seen that the composite hydrogen storage material pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com