Low-moisture-absorption-rate polymethacrylimide foam and preparation method thereof

A technology of polymethacrylimide and low moisture absorption, which is applied in the field of polymethacrylimide foam with low moisture absorption and its preparation, can solve problems such as loss, potential safety hazards, and reduced thermal insulation performance of foam materials, achieving Low moisture absorption rate, simple and easy preparation process, and the effect of avoiding the danger of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

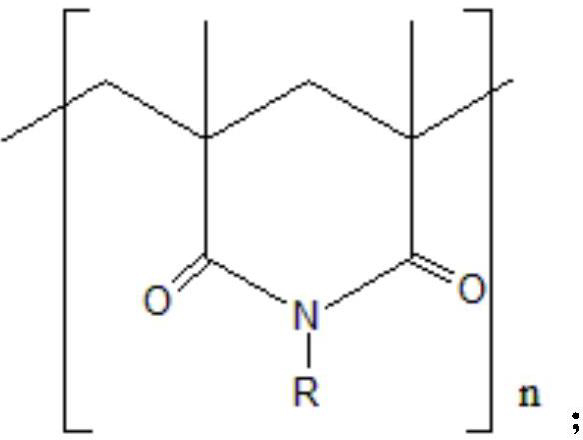

[0028] The polymethacrylimide foam with low moisture absorption rate described in this embodiment 1, the polymethacrylimide has the following repeating structural unit:

[0029]

[0030] Among them, R represents ethyl, 18000≤n≤22000.

[0031] The polymethacrylimide foam with low moisture absorption rate described in the present embodiment 1, in terms of mass percentage, the raw material composition is as follows:

[0032]

[0033] The preparation method of the low moisture absorption polymethacrylimide foam described in the present embodiment 1 is made up of the following steps:

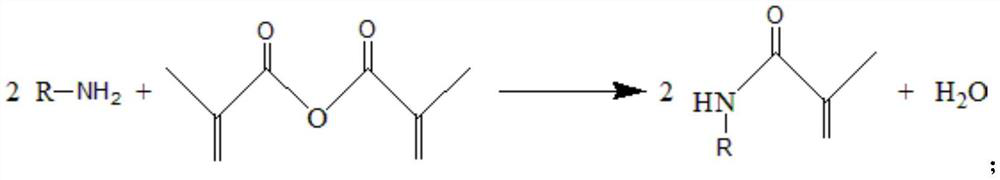

[0034] Weigh 90g ethylamine, 154g methacrylic anhydride, 172g methacrylic acid, 0.2g isopropanol, 0.5g ammonium phosphate, 0.3g azobisisobutyronitrile at room temperature and normal pressure, and mix them uniformly, Obtain a mixed liquid; heat the above mixed liquid to 80°C and react for 5 hours to obtain a plexiglass plate; then put the above-mentioned plexiglass plate into a blast oven at 18...

Embodiment 2

[0037] The polymethacrylimide foam with low moisture absorption rate described in Example 2, the polymethacrylimide has the following repeating structural unit:

[0038]

[0039] Wherein, R represents propyl group, 18000≤n≤22000.

[0040] The polymethacrylimide foam with low moisture absorption rate described in the present embodiment 2, in terms of mass percentage, the raw material composition is as follows:

[0041]

[0042] The preparation method of the polymethacrylimide foam with low moisture absorption rate described in this embodiment 2 consists of the following steps:

[0043] Weigh 104g propylamine, 154g methacrylic anhydride, 172g methacrylic acid, 0.15g propanol, 0.5g phosphoric acid ester, 0.3g dibenzoyl peroxide at room temperature and normal pressure, and mix them uniformly to obtain a mixed Liquid; heat the above mixed liquid to 75°C and react for 5 hours to obtain a plexiglass plate; then put the above plexiglass plate into a blast oven at 185°C for foam...

Embodiment 3

[0046] The low moisture absorption polymethacrylimide foam described in this embodiment 3, the polymethacrylimide has the following repeating structural unit:

[0047]

[0048] Among them, R represents ethyl, 18000≤n≤22000.

[0049] The polymethacrylimide foam with low moisture absorption rate described in this embodiment 3, in terms of mass percentage, has the following raw material composition:

[0050]

[0051] The preparation method of the polymethacrylimide foam with low moisture absorption rate described in this embodiment 3 consists of the following steps:

[0052] Weigh 90g ethylamine, 154g methacrylic anhydride, 172g methacrylic acid, 0.2g butanol, 0.4g phosphoric acid ester, 0.25g dibenzoyl peroxide at room temperature and normal pressure, and mix them uniformly to obtain Mix liquid; heat the above mixed liquid to 75°C, react for 5h to obtain a plexiglass plate; then put the above plexiglass plate into a blast oven at 180°C for foaming to obtain a PMI foam pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com