Reduced-weight composite wood-plastic profile and preparation method thereof

A technology of composite wood and profiles, applied in the field of wood-plastic production, can solve the problems of heavy weight and high surface temperature, and achieve the effect of ensuring strength, reducing surface temperature and reducing the total amount of profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

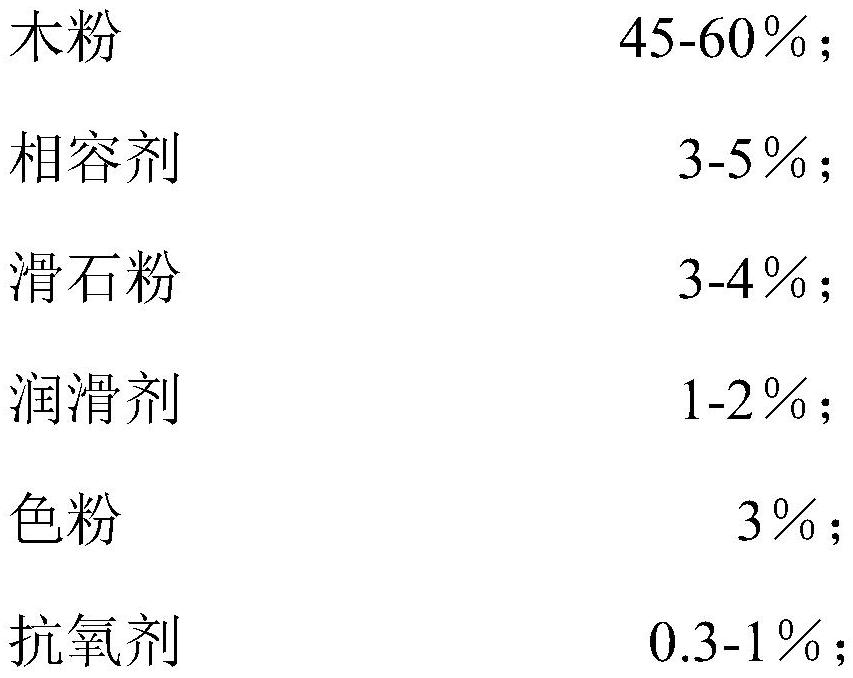

[0020] In this embodiment, the weight-reducing composite wood-plastic profile is composed of the following components by mass percentage:

[0021]

[0022] Wherein, the foaming agent is Matsumoto microsphere foaming agent or azo foaming agent. The lubricant is maleic anhydride grafted polyethylene wax. Increases fluidity through the combined action of talc and lubricants, while increasing the compatibility of wood flour and other ingredients.

[0023] The preparation method of the weight-reducing composite wood-plastic profile described in this embodiment comprises the following steps:

[0024] S1, put wood powder, compatibilizer, talcum powder, lubricant, toner, antioxidant, antifungal agent, high-density polyethylene into a high-speed stirring furnace and stir for at least 10 minutes, and then put it into a 75-square-meter double-water pull bar to make The granules are prepared in the granulator for standby, and the preparation temperature is controlled at 160°C-200°C; ...

Embodiment 2

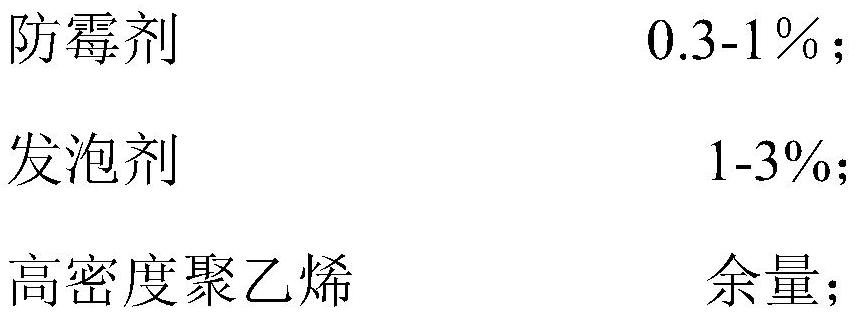

[0028] In this embodiment, the weight-reducing composite wood-plastic profile is composed of the following components by mass percentage:

[0029]

[0030] Wherein, the foaming agent is Matsumoto microsphere foaming agent or azo foaming agent. The lubricant is maleic anhydride grafted polyethylene wax. Increases fluidity through the combined action of talc and lubricants, while increasing the compatibility of wood flour and other ingredients.

[0031] The preparation method of the weight-reducing composite wood-plastic profile described in this embodiment comprises the following steps:

[0032] S1, put wood powder, compatibilizer, talcum powder, lubricant, toner, antioxidant, antifungal agent, high-density polyethylene into a high-speed stirring furnace and stir for at least 10 minutes, and then put it into a 75-square-meter double-water pull bar to make The granules are prepared in the granulator for standby, and the preparation temperature is controlled at 160°C-200°C; ...

Embodiment 3

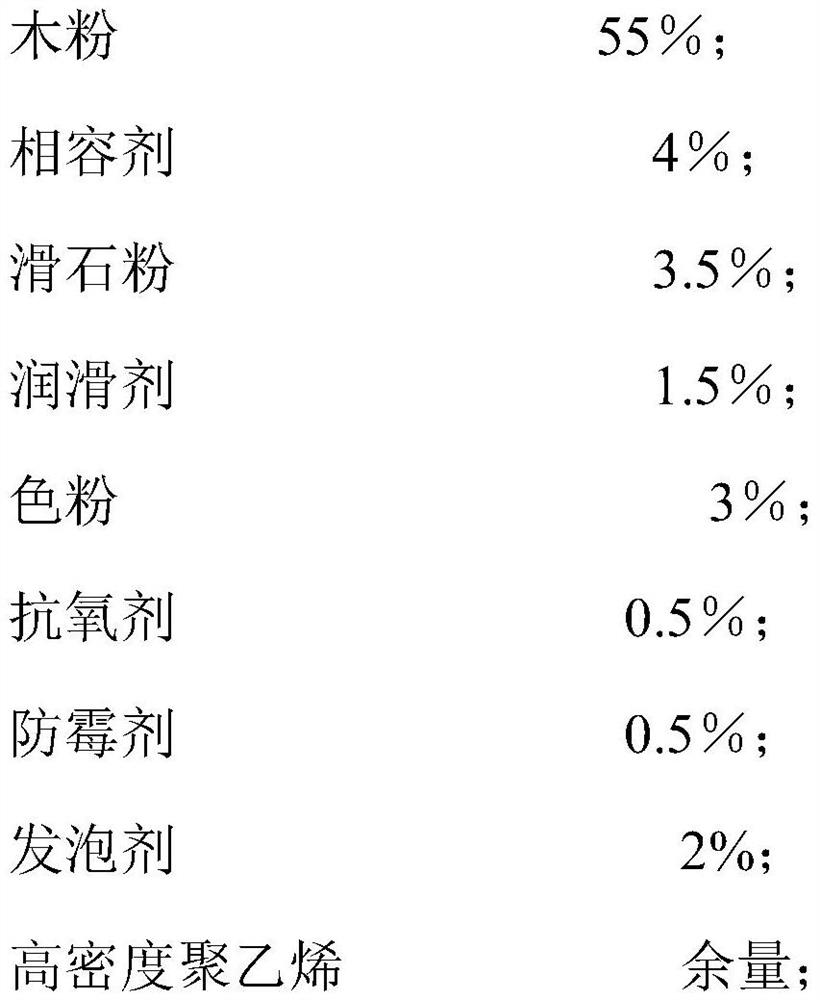

[0036] In this embodiment, the weight-reducing composite wood-plastic profile is composed of the following components by mass percentage:

[0037]

[0038] Wherein, the foaming agent is Matsumoto microsphere foaming agent or azo foaming agent. The lubricant is maleic anhydride grafted polyethylene wax. Increases fluidity through the combined action of talc and lubricants, while increasing the compatibility of wood flour and other ingredients.

[0039] The preparation method of the weight-reducing composite wood-plastic profile described in this embodiment comprises the following steps:

[0040] S1, put wood powder, compatibilizer, talcum powder, lubricant, toner, antioxidant, antifungal agent, high-density polyethylene into a high-speed stirring furnace and stir for at least 10 minutes, and then put it into a 75-square-meter double-water pull bar to make The granules are prepared in the granulator for standby, and the preparation temperature is controlled at 160°C-200°C; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap