HPS420WZ35 weather-resistant bridge plate with thickness of 100mm and production method for ensuring performance of HPS420WZ35 weather-resistant bridge plate

A technology of HPS420WZ35 and bridge plate, which is applied in heat treatment equipment, manufacturing tools, heat treatment process control, etc., can solve the problem of difficulty in maintaining performance of extra-thick and high-strength plates, and achieve the effect of matching strength and low-temperature impact toughness and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

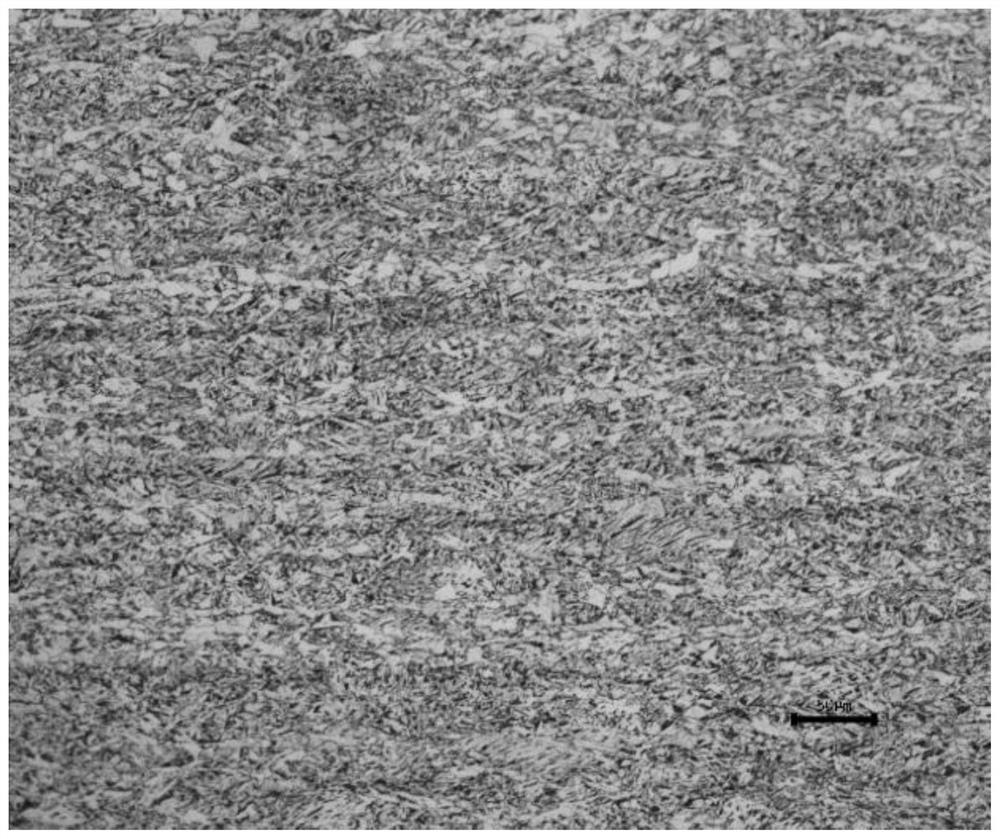

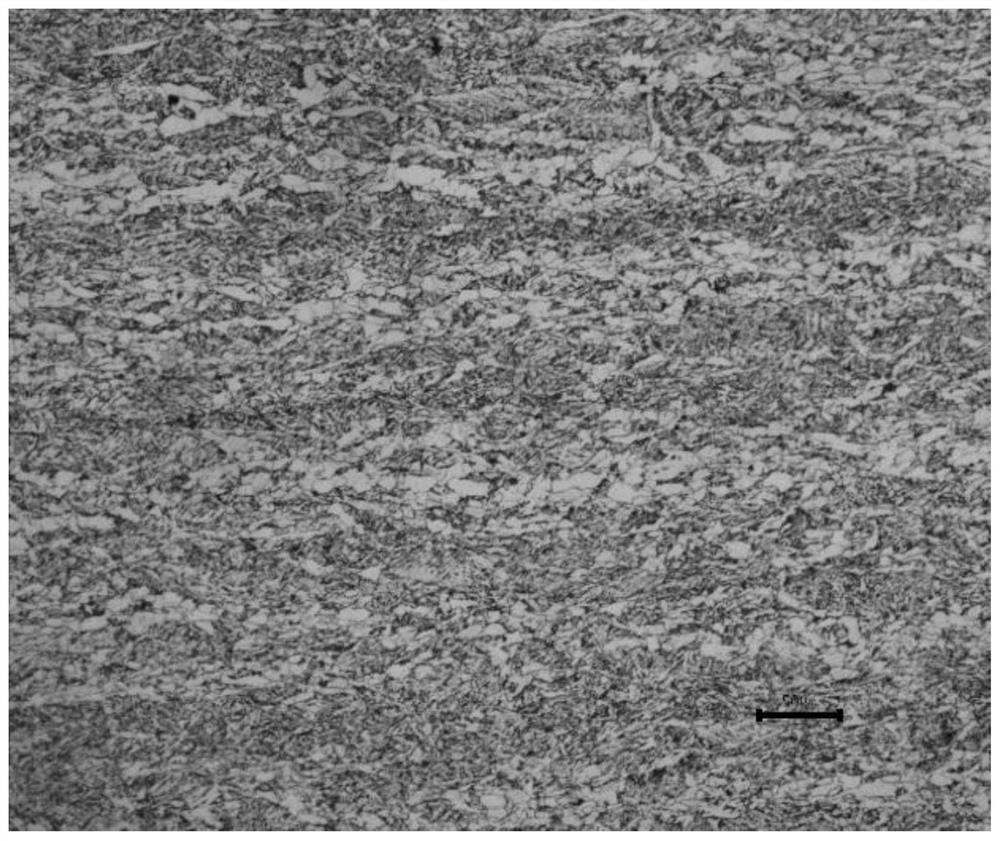

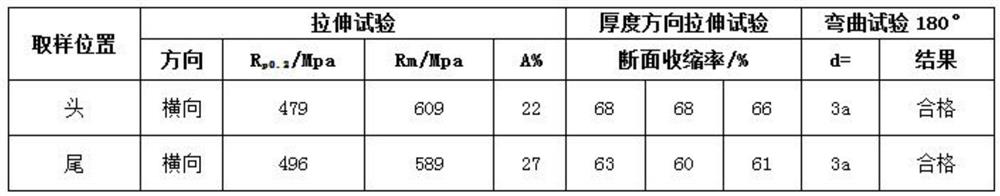

Image

Examples

Embodiment

[0022] A kind of HPS420WZ35 weather-resistant bridge plate with a thickness of 100mm is produced, the single weight of the steel plate is 20t, and the chemical composition (unit, wt%) is contained in the following mass percentage:

[0023] C: 0.06; Si: 0.18; Mn: 0.97; P: 0.08; S: 0.001; Als: 0.023; Nb: 0.051; 0.011; B: 0.0001; Sn: 0.0007; N: 0.003, and others are Fe and residual elements.

[0024] Embodiments of the present invention are achieved through the following steps:

[0025] 1) Billet selection: In order to ensure that the rough rolling process fully refines the grain size of the austenite recrystallization region and presses internal micro-defects, the steel billet thickness is 350mm and the compression ratio is 3.5;

[0026] 2) Billet treatment: the original iron oxide on the surface of the billet needs to be removed, and anti-oxidation paint should be applied;

[0027] 3) Billet heating: heating temperature 1050~1150℃, total heating time 9.16h, actual heating coe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com