Spraying industry waste gas treatment method with ozone catalytic functional ceramic membrane as catalytic separation material

A technology of functional ceramics and ozone catalysis, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of inability to clean waste gas, secondary pollution, etc., and achieve high-efficiency separation treatment and catalytic ozone oxidation, large-scale The effect of mechanical strength, good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

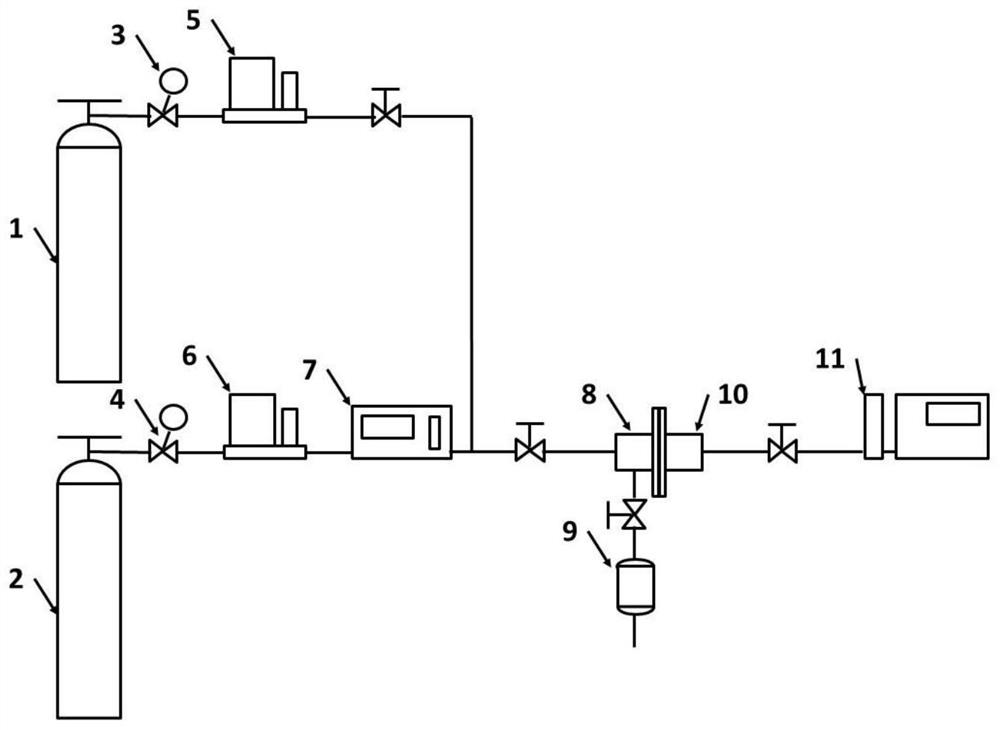

[0025] This embodiment provides a method for treating waste gas in the spraying industry using an ozone catalytic functional ceramic membrane as a catalytic separation material, including:

[0026] A, preparation of ozone catalytic functional ceramic membrane;

[0027] B. Use the ozone catalytic functional ceramic membrane as a catalytic separation material to treat waste gas from the spraying industry.

[0028] preferred, such as figure 1 As shown, the preparation method of ozone catalytic functional ceramic membrane is as follows:

[0029] (1) Pretreatment of substrate ceramic membrane

[0030] The pore diameter of the base ceramic membrane used in the present invention is about 0.1 μm. Before the preparation, the base ceramic membrane was ultrasonically cleaned several times (at least 3 times) with deionized water and ethanol respectively, so as to remove impurities on the surface of the base ceramic membrane. Then put it into a muffle furnace, bake it at 580-600°C for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap