Surface treatment process of high-strength corrosion-resistant screw

A surface treatment and corrosion-resistant technology, applied in threaded products, metal material coating technology, metal processing equipment, etc., can solve the problems of double-head adjustment screw thread length, bumps, easy to bend, etc., to increase the smoothness, Excellent corrosion resistance, reasonable process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] 1. Cold heading forming: Preliminarily shape the stainless steel wire for cold heading through the cold heading mold to obtain the primary product. The above primary product is vibrated and cleaned with a vibrating grinder. During the cleaning process, stainless steel cleaning agent is first added to remove oil stains. After the oil stain is removed, add stainless steel brightener, and finally wash with water and vibrate for 45 minutes;

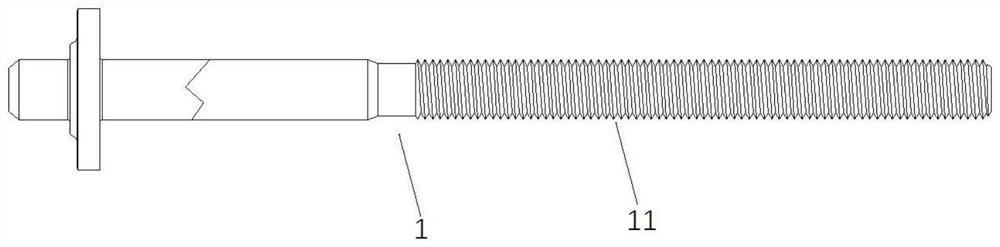

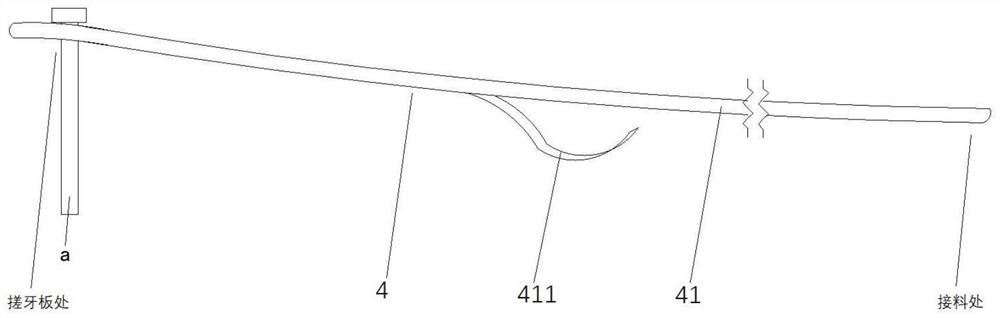

[0046] 2. Turning and rubbing: the head of the cleaned primary product is turned by CNC turning technology to ensure that the size and surface roughness of the turned head meet the customer's requirements, and the surface roughness is less than 0.8, and the screw blank a ; Then use a rubbing board to carry out rubbing and straightening processing on the screw blank a to obtain the screw 1;

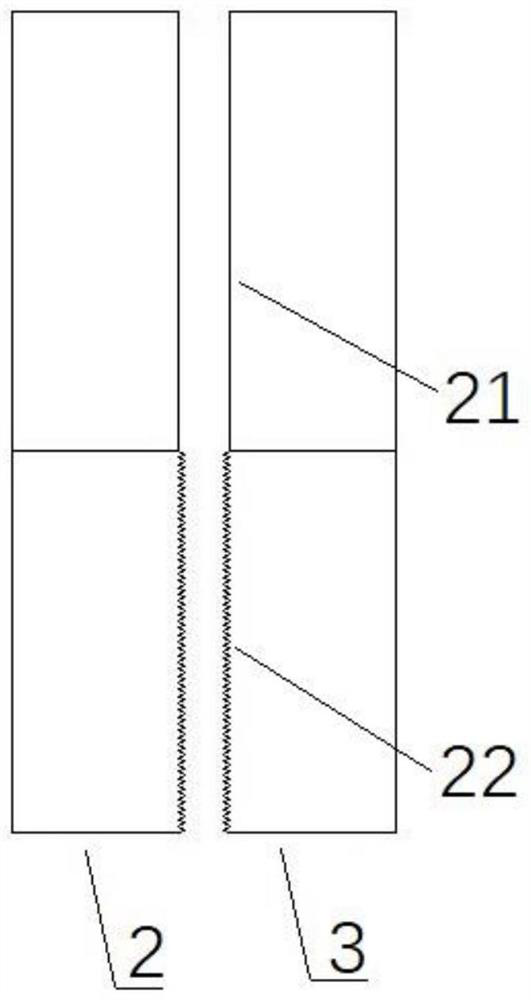

[0047] 3. Surface treatment: Before surface treatment, it is necessary to use inspection tools to test the straightness of the screw 1 after rubbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com