Steam waste heat recycling system for autoclaved aerated concrete blocks

A concrete block and steam waste heat technology, applied in the field of autoclave, can solve the problems of high temperature tensile stress, steam heat loss, cracking of concrete block concrete structure, etc., and achieve the effect of uniform cooling and ensuring uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

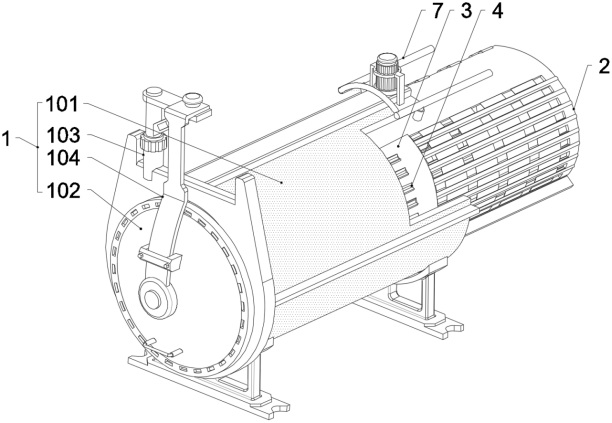

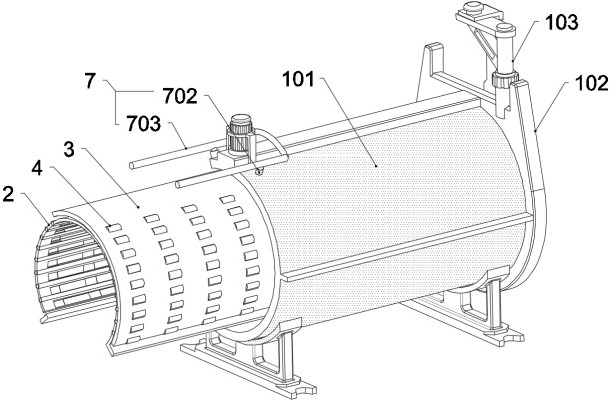

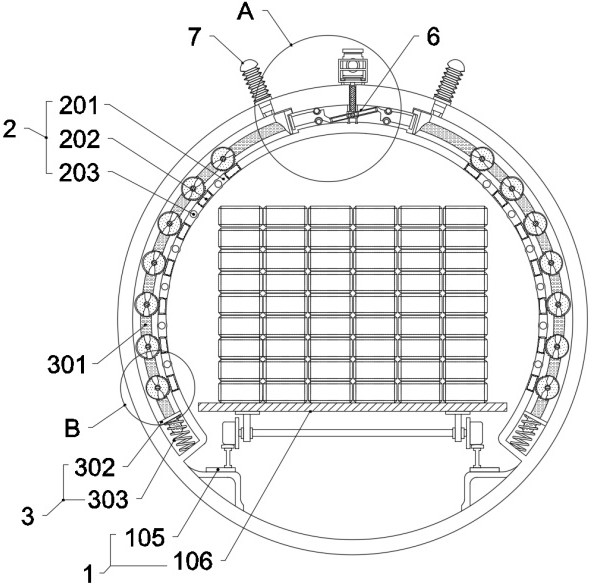

[0039] To more clearly illustrate the structural features and efficacy of the present invention, the present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] See Figure 1-Figure 6, one embodiment of the present invention in an autoclaved aerated concrete block steam waste heat recovery system, comprising a kettle body member 1, the kettle body member 1 comprising the main kettle body 101 and the kettle cover 102, the waste heat recovery system further comprises: lining wall assembly 2, the lining wall assembly 2 comprises an inner liner sleeve 201 and an intake tank 202, the liner sleeve 201 is fixed to be assembled on the inner wall of the main kettle body 101, the upper cloth thereof is provided with several intake tanks 202, The air intake tank 202 array is laid on the liner sleeve 201; sleeve mechanism 3, the sleeve mechanism 3 comprises two sets of mobile sleeve 301, two sets of mobile sleeve 301 mirror ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com