Stall adjusting device of raw material stirrer for electronic product processing

A technology for electronic products and mixers, which is applied in the field of stall adjustment devices for raw material mixers used in electronic product processing. It can solve the problems of excessive speed, the speed of the output shaft of the mixer cannot be kept constant, and affect the processing quality, so as to prevent the speed from being too fast and increase the speed. , the effect of maintaining the working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

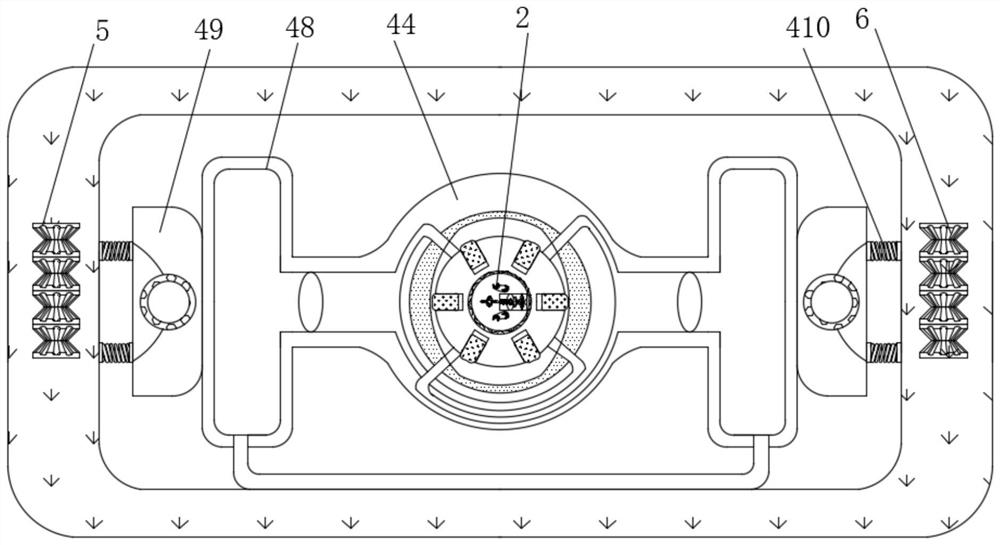

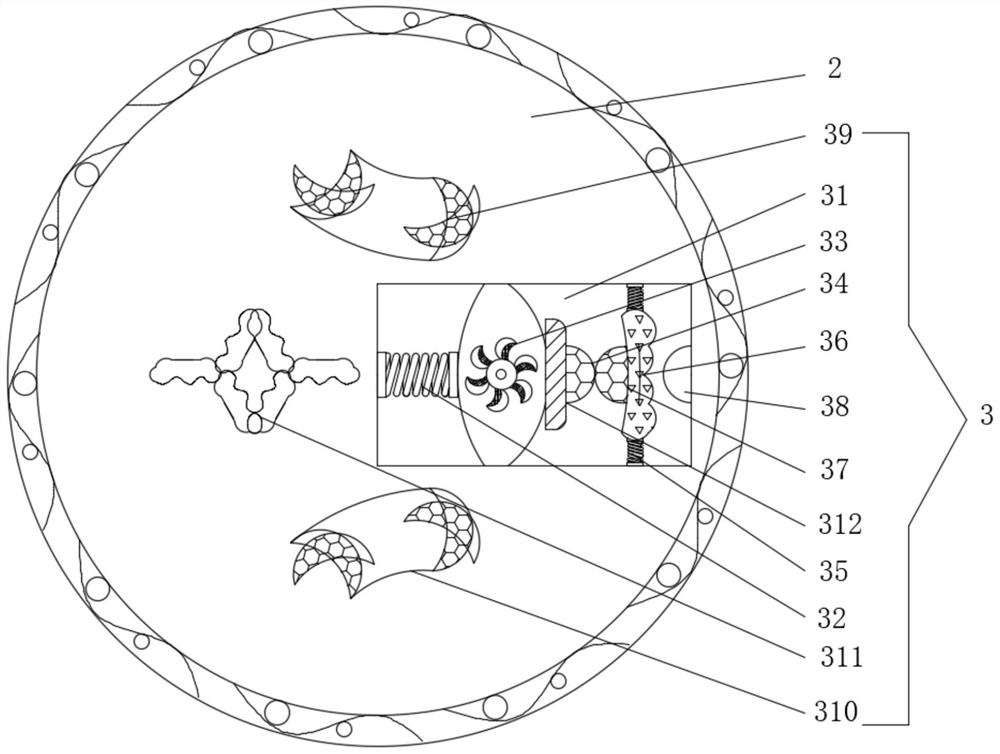

[0027] see figure 1 and figure 2 , a raw material mixer stall adjustment device for electronic product processing, comprising a device casing 1 and a stirring shaft 2, the inside of the device casing 1 is movably connected to the stirring shaft 2, the inside of the stirring shaft 2 is fixedly connected to a speed measuring assembly 3, and the outside of the stirring shaft 2 A speed regulating component 4 is fixedly connected, a first electromagnet 5 is fixedly connected inside the equipment housing 1, and a second electromagnet 6 is fixedly connected inside the equipment housing 1;

[0028] The speed measuring assembly 3 includes a movable groove 31, the inner wall of the movable groove 31 is fixedly connected with a first spring 32, the outer side of the first spring 32 is fixedly connected with a dielectric plate 33, the outer side of the dielectric plate 33 is fixedly connected with a moving contact 34, and the inner wall of the movable groove 31 is fixedly connected with ...

Embodiment 2

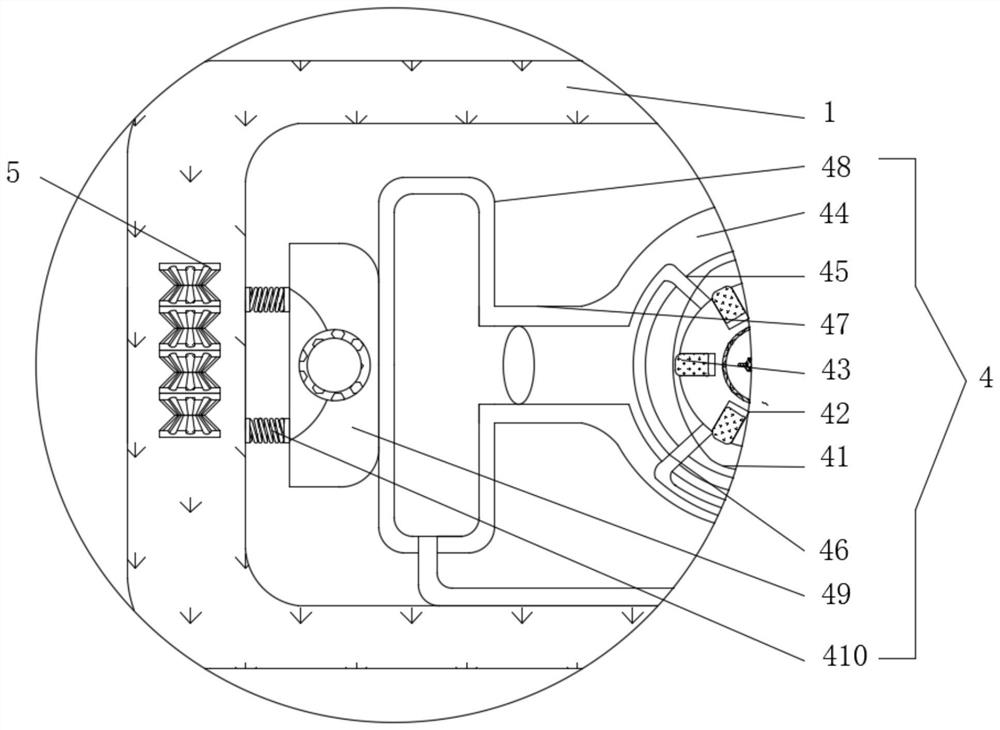

[0030] see figure 1 , image 3 and Figure 4 , a raw material mixer stall adjustment device for electronic product processing, comprising a device casing 1 and a stirring shaft 2, the inside of the device casing 1 is movably connected to the stirring shaft 2, the inside of the stirring shaft 2 is fixedly connected to a speed measuring assembly 3, and the outside of the stirring shaft 2 A speed regulating component 4 is fixedly connected, a first electromagnet 5 is fixedly connected inside the equipment housing 1, and a second electromagnet 6 is fixedly connected inside the equipment housing 1;

[0031] The speed regulating assembly 4 includes a speed regulating shaft 41, and a moving groove 42 is provided inside the speed regulating shaft 41, and a blade 43 is movably connected inside the moving groove 42, and a hydraulic sealing casing 44 is fixedly connected inside the equipment housing 1, and the hydraulic sealing casing 44 An oil inlet oil passage 45 is opened inside, an...

Embodiment 3

[0033] see Figure 1-4, a raw material mixer stall adjustment device for electronic product processing, comprising a device casing 1 and a stirring shaft 2, the inside of the device casing 1 is movably connected to the stirring shaft 2, the inside of the stirring shaft 2 is fixedly connected to a speed measuring assembly 3, and the outside of the stirring shaft 2 A speed regulating component 4 is fixedly connected, a first electromagnet 5 is fixedly connected inside the equipment housing 1, and a second electromagnet 6 is fixedly connected inside the equipment housing 1;

[0034] The speed measuring assembly 3 includes a movable groove 31, the inner wall of the movable groove 31 is fixedly connected with a first spring 32, the outer side of the first spring 32 is fixedly connected with a dielectric plate 33, the outer side of the dielectric plate 33 is fixedly connected with a moving contact 34, and the inner wall of the movable groove 31 is fixedly connected with There is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com