Pressing structure capable of performing double-sided printing based on reflective cloth printing machine

A technology of reflective cloth printing and double-sided printing, which is applied to general parts of printing machinery, printing machines, rotary printing machines, etc., to increase flexibility, meet printing processing needs, and improve work speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

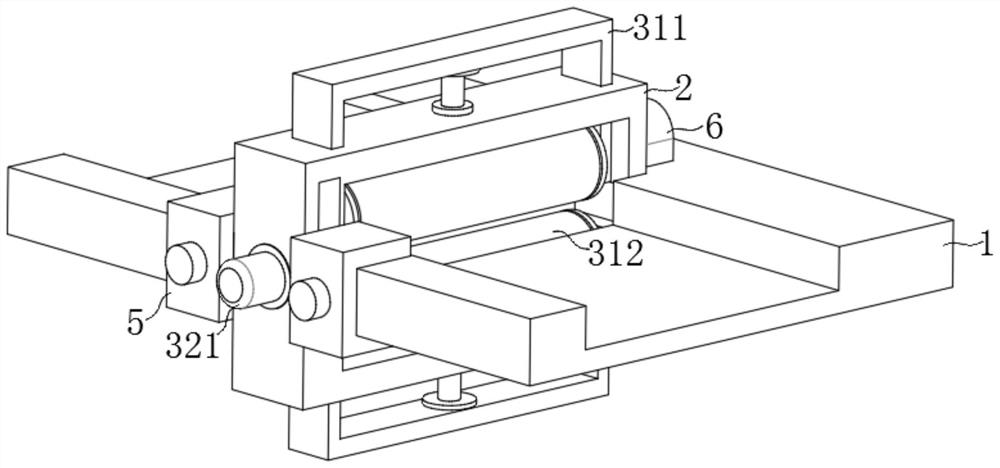

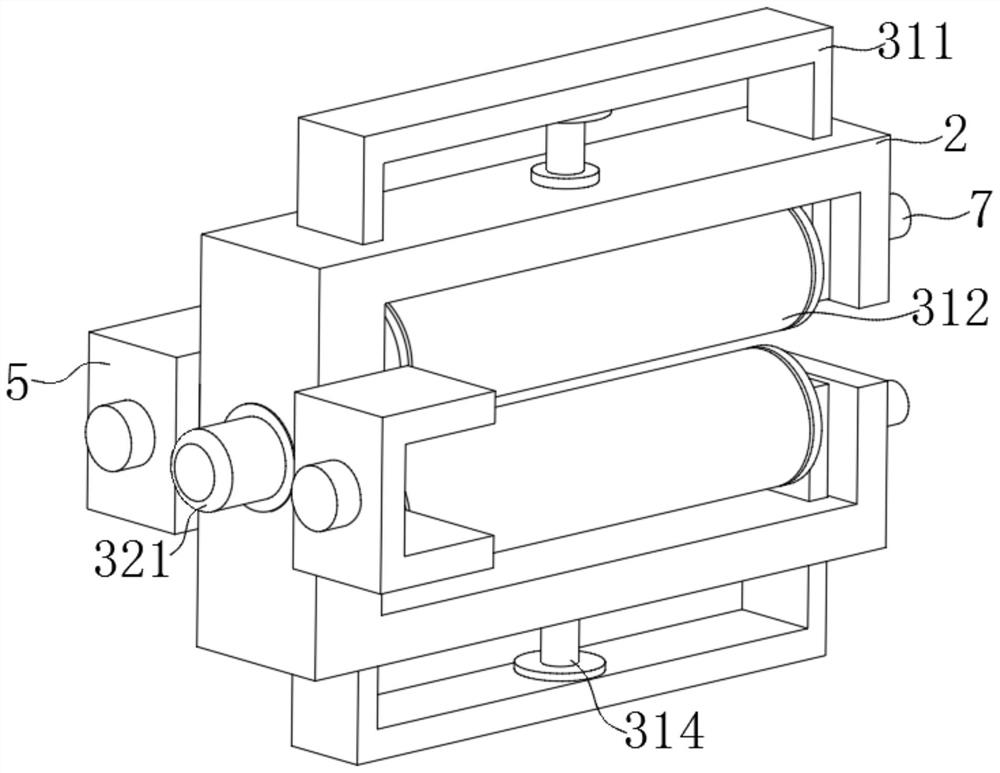

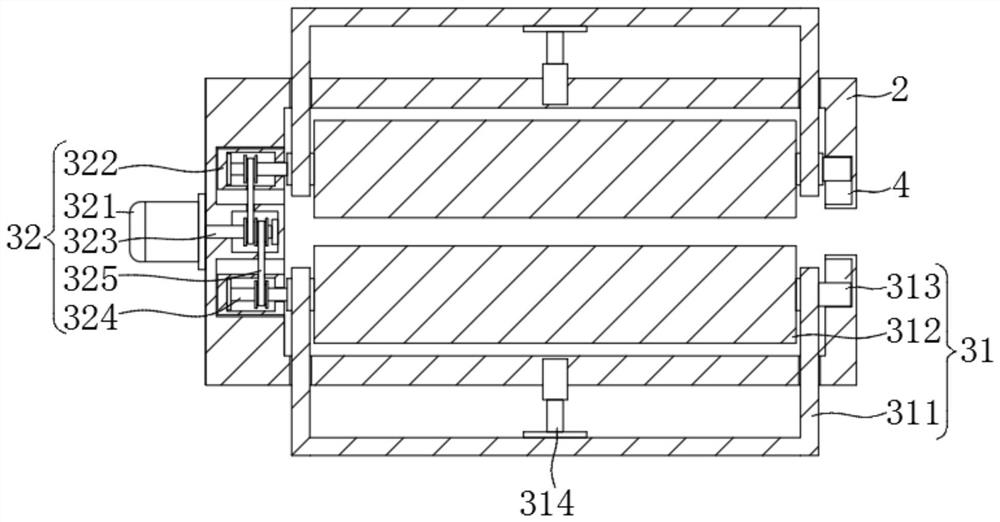

[0043] Please refer to figure 1 , figure 2 , image 3 , Figure 4 ,in figure 1 It is a structural schematic diagram of the first embodiment of the double-sided printing press material structure based on the reflective cloth printing machine provided by the present invention; figure 2 for figure 1 Schematic diagram of the printed structure shown; image 3 for figure 2 The schematic diagram of the internal structure of the main frame shown;

[0044] Figure 4 for figure 1 A schematic of the exterior of the console is shown. Based on the press material structure for double-sided printing for reflective cloth printing machines, including:

[0045] console 1;

[0046] The main frame 2, the main frame 2 is arranged on the operating table 1, the printing structure 3 for double-sided printing of the reflective cloth is arranged on the main frame 2, and the printing structure 3 includes two Adjust the function and keep the embossing roller assembly 31 symmetrical up and ...

no. 2 example

[0064] Please refer to Figure 5 , Figure 6 and Figure 7 , based on the first embodiment of the present invention, a press material structure that can be used for double-sided printing based on reflective cloth printing machines, and the second embodiment of the present invention provides another press structure that can be used for double-sided printing based on reflective cloth printing machines For the binder structure, the second embodiment does not hinder the independent implementation of the technical solution of the first embodiment.

[0065] Specifically, the present invention provides another kind of press material structure that can be printed on both sides based on reflective cloth printing machine. The difference is that:

[0066] The main body frame 2 is provided with a fixing structure 8 for fixing the connecting seat 6, the fixing structure 8 includes a rotating part 81, and the rotating part 81 rotates on the main body frame 2, and the rotating part 81 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com