Production process of large-particle potassium fluoride

A production process and technology of potassium fluoride, applied in the directions of alkali metal fluoride, alkali metal halide shape preparation, alkali metal halide preventing moisture absorption, etc., can solve the problem of difficult long-distance transportation, small potassium fluoride particles, and short storage time. and other problems, to achieve the effect of easy long-distance transportation, long storage time and short storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

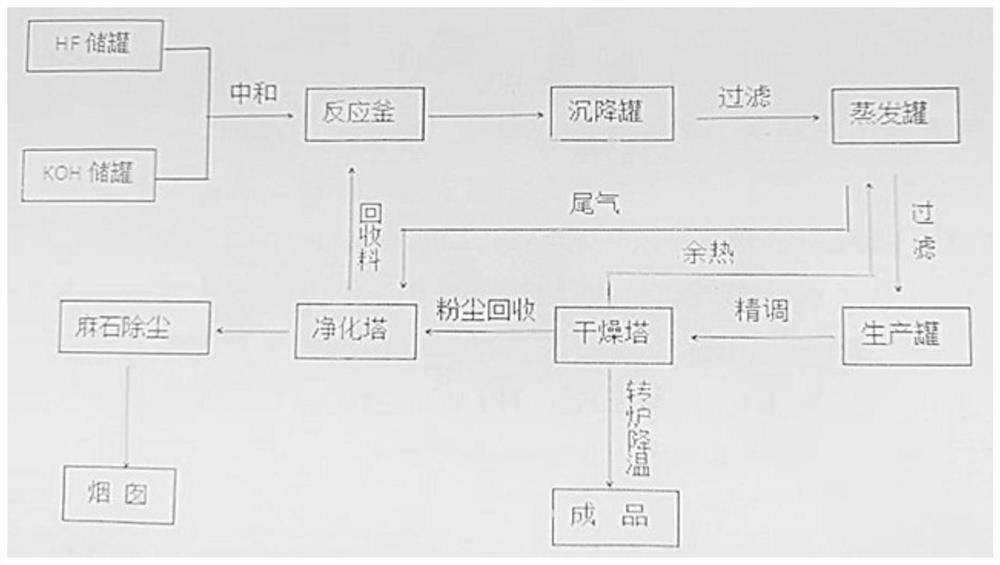

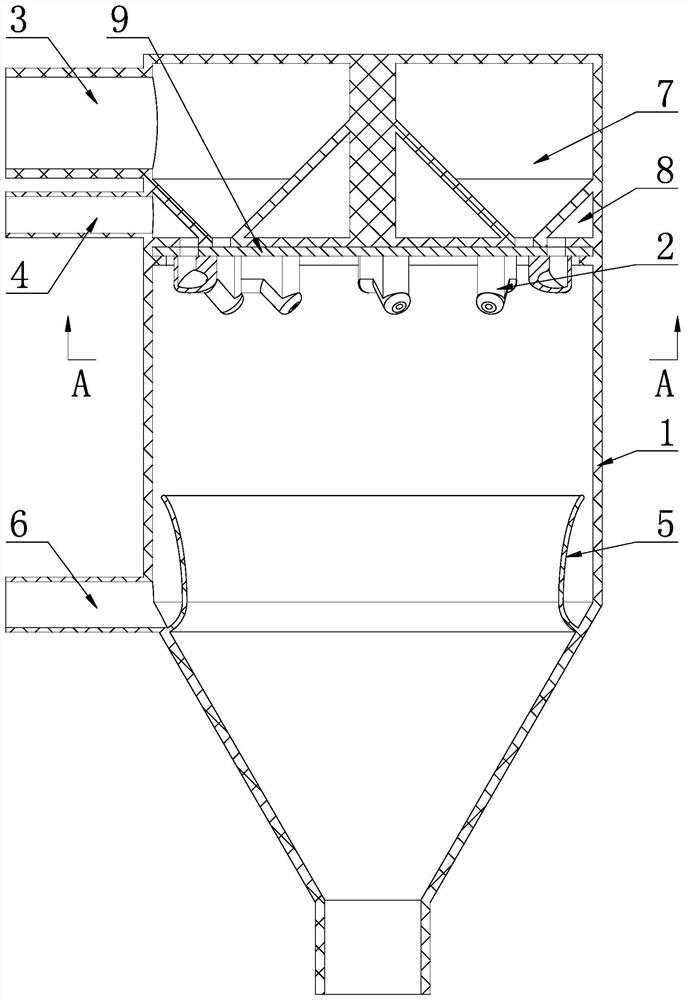

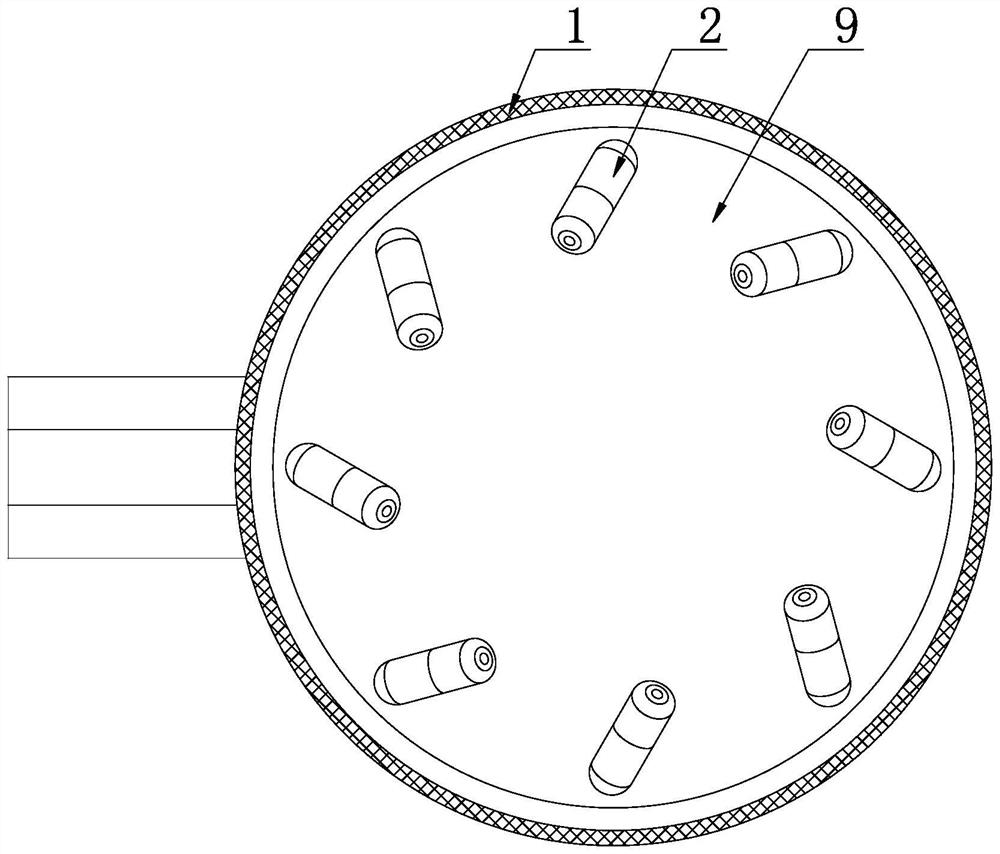

[0036] Such as Figure 1-5 Shown, a kind of large particle potassium fluoride production technique comprises the steps:

[0037] S1, batching, 48% KOH lye and HF acid solution are stirred and neutralized in the reactor to obtain a KF solution, and the obtained KF solution is input into a settling tank and left to stand;

[0038] S2, adjust, input the KF solution after standing in step S1 into the production tank, and accurately adjust the pH value of the KF solution;

[0039] S3, drying, the KF solution adjusted in step S2 is pumped into the spray gun 2 on the top of the drying tower, the feed rate of the KF solution and the air pressure in the drying tower are adjusted, and the KF solution is dried to obtain large particle potassium fluoride.

[0040] In described step S1, KOH lye is first input into the reaction kettle, the liquid level of KOH lye is higher than the HF acid outlet of the reaction kettle, and then the stirring is started, and the HF acid is slowly added into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com