PP-R/PBT alloy material and preparation method and application thereof

A technology of PP-R and alloy materials, applied in application, chemical instruments and methods, heating methods, etc., can solve the problems of twisting and deformation of water pipes, insufficient dimensional stability, poor creep resistance and rigidity of PP-R pipes, etc. , to achieve the effect of improving the pressure resistance, good mechanical properties and dimensional stability, and low linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

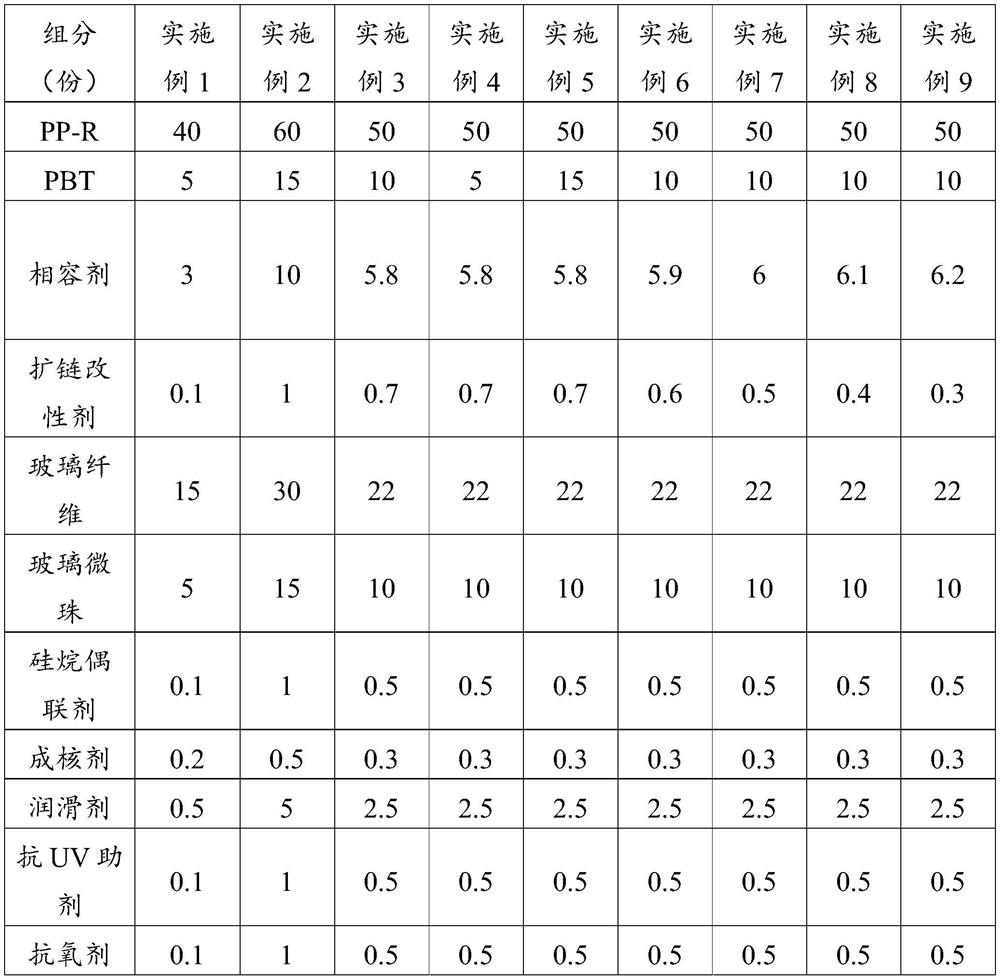

[0039] Embodiments 1 to 9 provide a PP-R / PBT alloy material, which is made from the formula in Table 1, and the preparation method is as follows:

[0040] (1) Add the glass microspheres and the silane coupling agent into the mixer, and mix them uniformly at a speed of 50 to 85 rpm to obtain activated glass microspheres;

[0041] (2) In addition to the glass fiber, add the remaining components in the formula and the activated glass microspheres prepared in step (1) into the mixer, and mix for 5 minutes at 100-150 rpm to obtain a uniform mixture;

[0042] (3) Put the mixture into the twin-screw extruder, control the extrusion temperature to 190-230°C, and the screw speed to 200-500rpm. After the mixture is in a molten state, add glass fiber to the middle section of the extruder for blending. Extruding, drawing and granulating to obtain the PP-R / PBT alloy material.

[0043] Table 1

[0044]

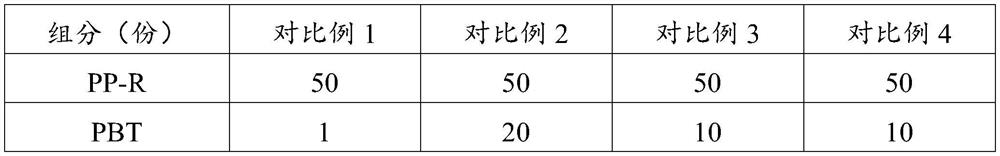

[0045] Comparative Examples 1-4 provide a PP-R / PBT alloy material, which is prepare...

Embodiment 10

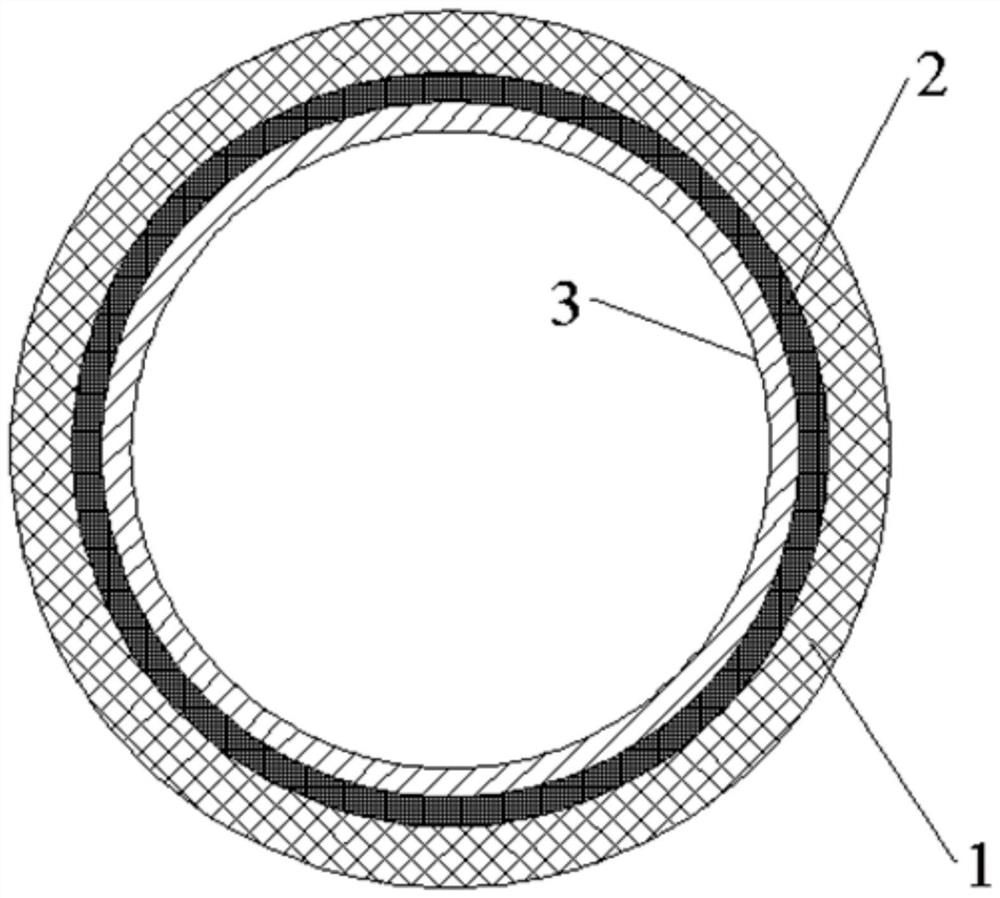

[0059] Embodiment 10 provides a composite pipe, such as figure 1 As shown, the composite pipe is a three-layer composite structure, followed by PP-R outer layer 1, PP-R / PBT middle layer 2 and PP-R inner layer 3, PP-R outer layer, PP-R / PBT middle layer The wall thickness ratio of the PP-R inner layer is 1:1:1.3.

[0060] The PP-R outer layer and the PP-R inner layer are respectively made of PP-R resin, and the PP-R / PBT middle layer is made of the PP-R / PBT alloy material of Example 1. The composite pipe is made by a conventional three-layer co-extrusion method, and will not be repeated here.

Embodiment 11

[0062] Embodiment 11 provides a kind of composite pipe, and its difference with embodiment 10 is only: the PP-R / PBT intermediate layer of embodiment 11 is made of the PP-R / PBT alloy material of embodiment 2, other and embodiment 10 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com