Preparation method of strawberry cheese flavored yogurt

A flavor and strawberry technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of low degree of automation of production equipment, single product structure, and dependence of starter on foreign strains, etc., to achieve better taste, fine texture, Solid state effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing strawberry cheese flavored yoghurt, comprising the following steps:

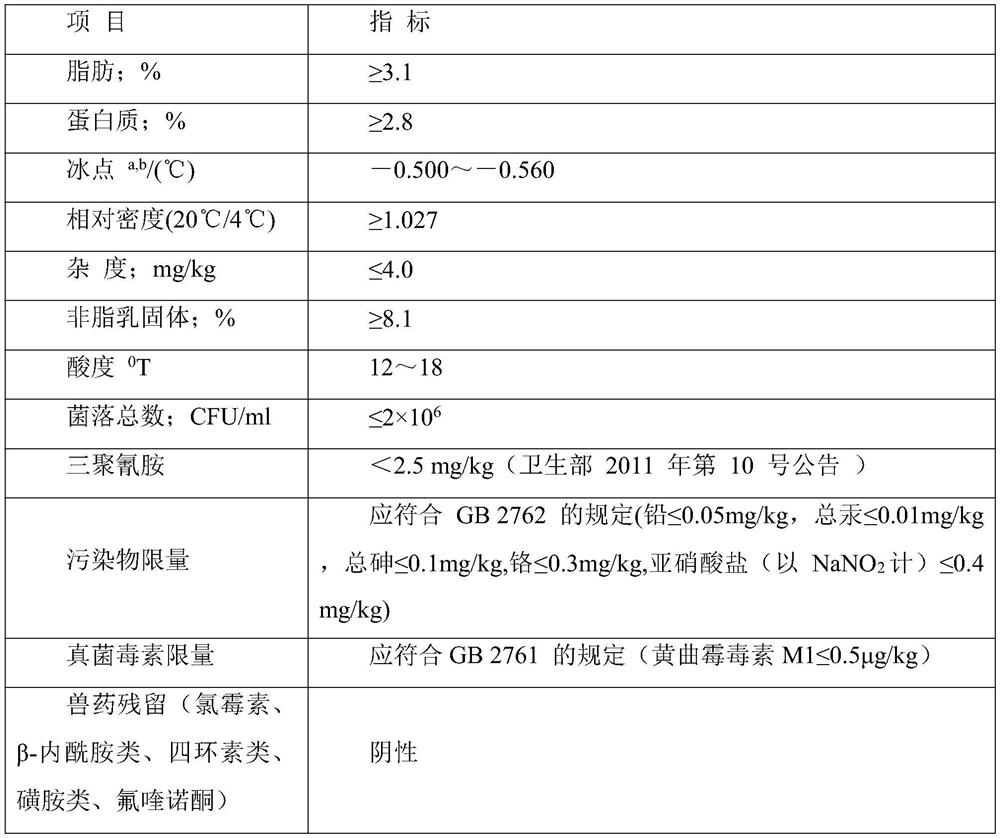

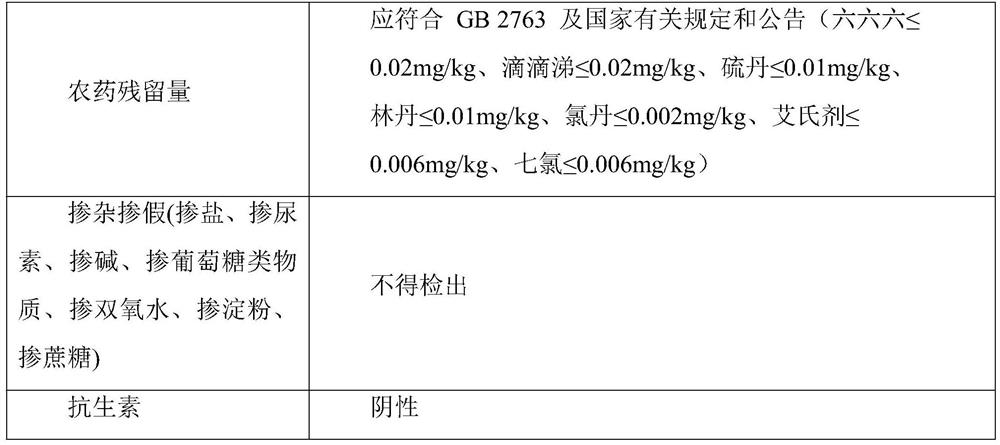

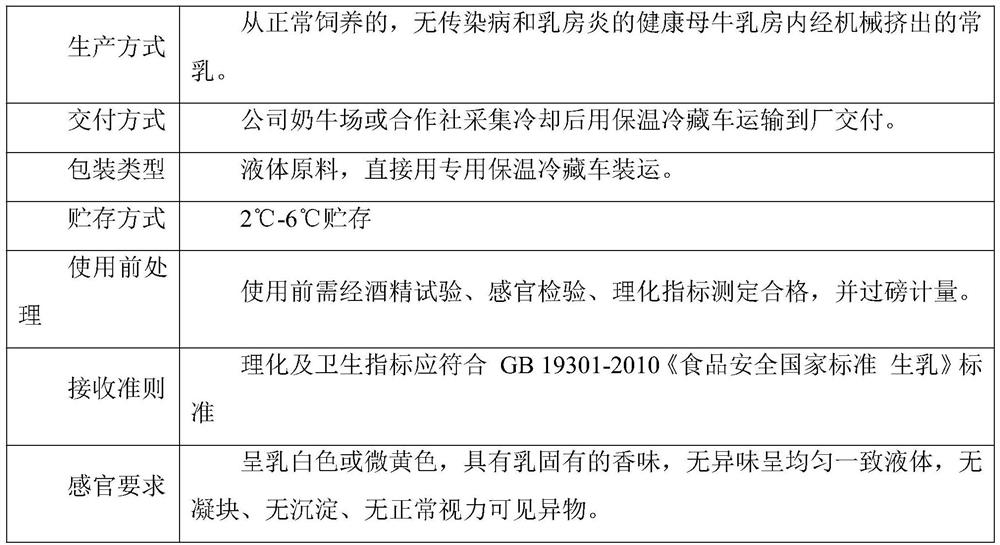

[0031] (1) Milk cleansing: the raw milk is centrifuged to remove the impurities in the milk, and the milk is cleaned, cooled to 2-6°C, and stored;

[0032] (2) Ingredients: Warm up the stored raw milk to 45-55°C, add whey protein powder, circulate and stir for 4-8 minutes, then let it stand for hydration for 20-50 minutes; after hydration, add white sugar, sweetened condensed milk, cream, stabilizer , lactic acid bacteria, egg yolk liquid, strawberry cheese jam and stirring for 5-15min to obtain the mixed ingredient emulsion;

[0033] Add strawberry cheesecake-flavored fruit sauce (containing cochineal) ≥ 6%, so that the flavored yogurt has the unique flavor of the fruity mixed sauce, enriching the existing flavored yogurt products;

[0034] (3) Temporary storage: cooling the obtained mixed ingredient emulsion to 2-12°C for constant volume and then tempor...

Embodiment 1

[0078] This embodiment provides a method for preparing strawberry cheese flavored yoghurt, comprising the following steps:

[0079] (1) Milk cleansing: the raw milk is centrifuged to remove impurities in the milk, and the milk is cleaned, cooled to 2°C, and stored;

[0080] (2) Ingredients: Warm the stored raw milk to 45°C, add whey protein powder, circulate and stir for 4 minutes, then let it stand for hydration for 20 minutes; after hydration, add white sugar, sweetened condensed milk, cream, stabilizer, lactic acid bacteria, egg yolk liquid, Strawberry cheese jam and the mixed ingredient emulsion that stirred for 5min;

[0081] (3) Temporary storage: Cool the obtained mixed ingredient emulsion to 2°C for constant volume and then temporarily store; the temporary storage temperature is 2°C, and the temporary storage time does not exceed 4 hours;

[0082] (4) Homogenization: pass the temporarily stored emulsion into the sterilizer to perform homogenization under the condition...

Embodiment 2

[0089] This embodiment provides a method for preparing strawberry cheese flavored yoghurt, comprising the following steps:

[0090] (1) Milk cleaning: the raw milk is centrifuged to remove the impurities in the milk, and the milk is cleaned, cooled to 6°C, and stored;

[0091] (2) Ingredients: Warm the stored raw milk to 55°C, add whey protein powder, circulate and stir for 4-8 minutes, then let stand for hydration for 50 minutes; after hydration, add white sugar, sweetened condensed milk, cream, stabilizer, lactic acid bacteria, egg yolk Liquid, strawberry cheese jam and the mixed ingredient emulsion obtained by stirring for 15min;

[0092] (3) Temporary storage: Cool the obtained mixed ingredient emulsion to 12°C for constant volume and then temporarily store; the temporary storage temperature is 12°C, and the temporary storage time does not exceed 4 hours;

[0093] (4) Homogenization: pass the temporarily stored emulsion into the sterilizer to perform homogenization under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com