Water distribution operation method for secondary cooling section of billet continuous casting machine

A billet continuous casting and operation method technology, applied in the field of metallurgy, can solve problems such as casting speed fluctuations, breakouts, billet cracks, etc., and achieve the effect of reducing quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

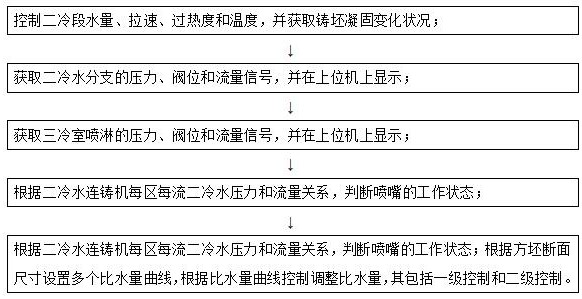

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, there are four types of billet cross-section design, in which the main cross-section is 165×165mm square billet cross-section, and 10 specific water volume curves are designed for each cross-section, and the ratios are from 1# curve, 2# curve, 3# curve, 4 #curve...10# curve, the current curves correspond to the following: 1# curve corresponds to 1.2 specific water volume, 2# curve corresponds to 1.4 specific water volume, 3# curve corresponds to 1.6 specific water volume, and the other 7 curves (4# curve...10 #curve) can be adjusted according to production needs.

[0033] Now take 1# curve 1.2 specific water volume as an example, adopt primary control, the specific values of the primary control are as follows: foot roll section: when pulling speed<0.4 m / min, Q=0.5; pulling speed≥0.4m / min , <2.5 m / min, Q=K(1.39V+7.84) m3 / h; when the casting speed is ≥2.5m / min, Q=K(1.01V2-0.34V+5.87) m3 / h;

[0034] One stage of spraying: when the casting speed is le...

Embodiment 2

[0046] Install pressure transmitters, regulating valves and flowmeters on the secondary cooling branch pipes to detect the pressure, valve position and flow signals of each branch pipe, in which the signals are transmitted to the host computer through wired or wireless, and the signal data is transmitted through tables or images The form is displayed for easy viewing by the staff.

Embodiment 3

[0048] After the casting slab is pulled out from the copper tube of the crystallizer, it passes through the secondary cooling fan-shaped section. If the secondary cooling spray pipe and the bracket are fixed, the casting slab will deviate in the secondary cooling chamber, which will easily lead to uneven cooling of the casting slab, resulting in Appearance defects such as bulging and off-square; in this embodiment, by changing the connection mode between the spray pipe and the support in each area of the second cold room to an adjustable connection, the centering and angle adjustment of the spray bar can be realized, and the casting billet can be cooled. More uniform; Wherein, the connection mode of the spray pipe and the bracket is bolt connection, and the position of the spray pipe can be adjusted by adjusting the screwing depth of the bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com