Intelligent production line for plate springs

A production line and intelligent technology, applied in the field of leaf spring production, can solve problems such as inaccurate position, unadjusted steel plates, and steel plates that fail to meet requirements, and achieve the effects of avoiding position deviation, improving efficiency, improving processing efficiency and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

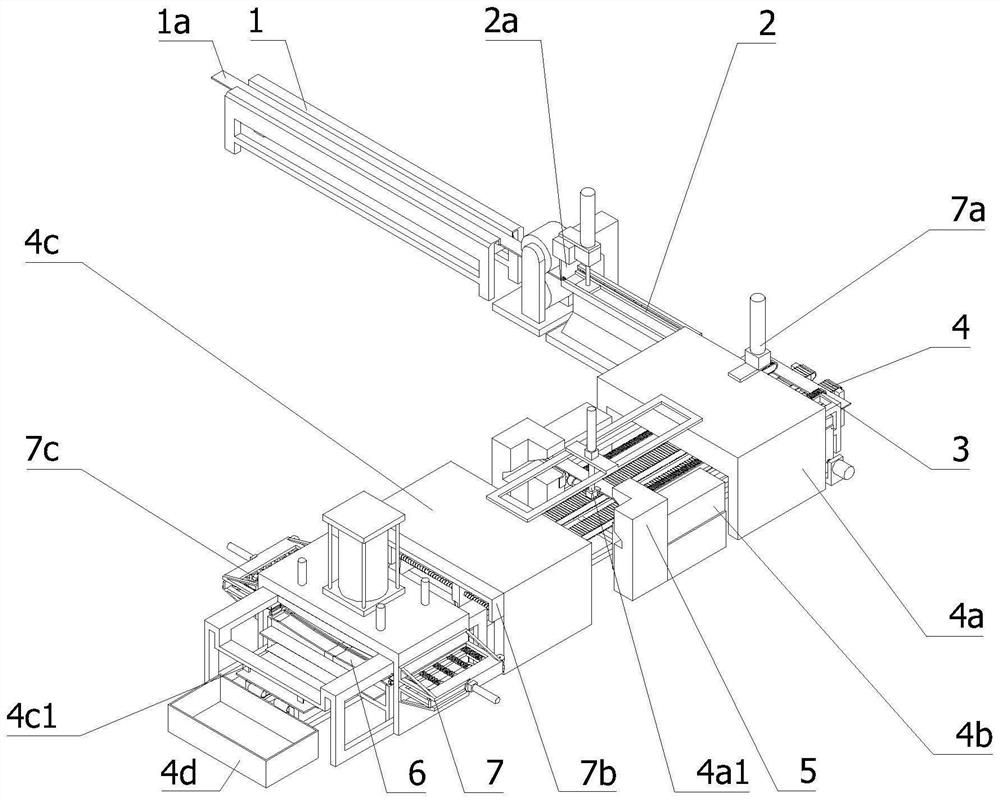

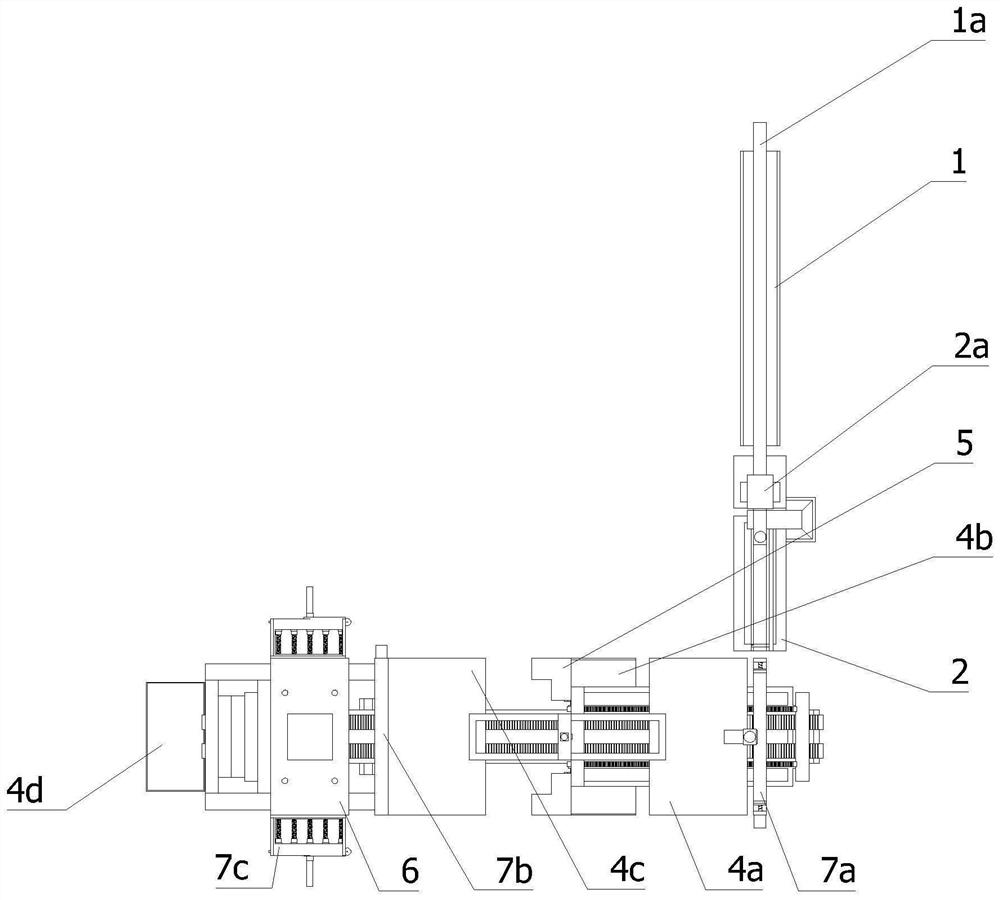

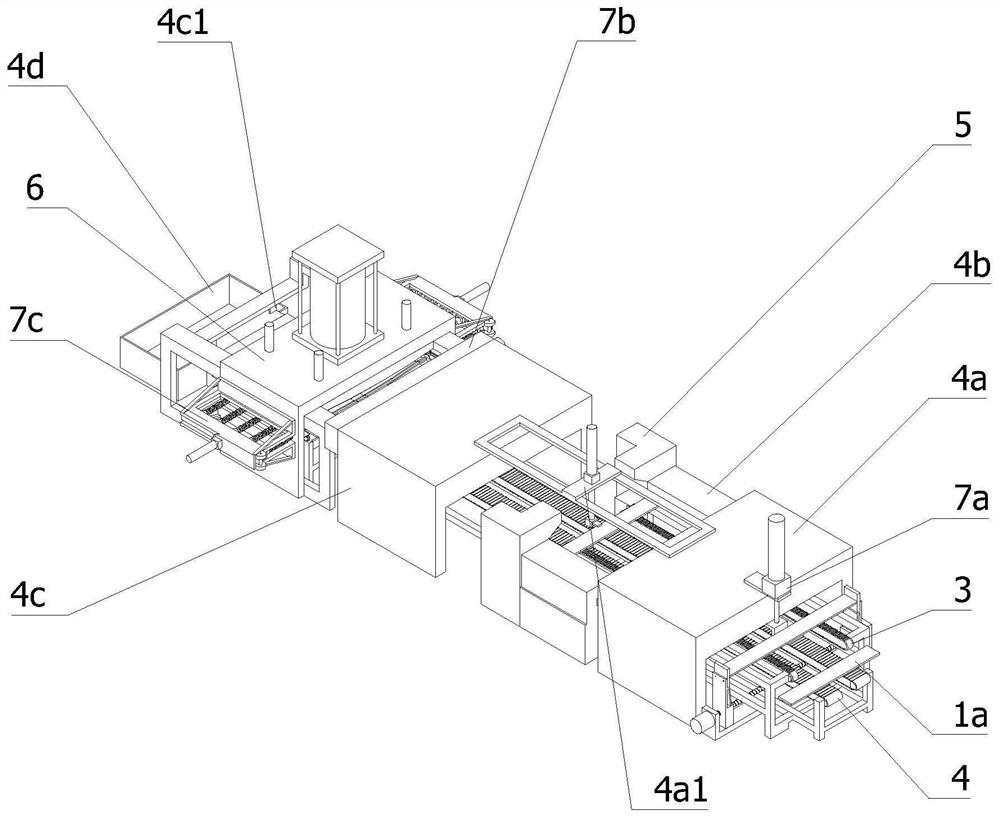

[0052] Such as Figure 1-Figure 11 As shown, this application provides:

[0053] An intelligent production line for leaf springs, including a belt conveyor 1, a shearing platform 2, and a shearing device 2a arranged between the belt conveyor 1 and the shearing platform 2, the side of the shearing platform 2 is from high to A first chain slat conveyor 3 and a second chain slat conveyor 4 are provided in sequence, the conveying direction of the first chain slat conveyor 3 and the second chain slat conveyor 4 are the same, and the second chain slat conveyor 4 A quenching chamber 4a, a local calciner 4b, an integral calciner 4c, and a cooling pool 4d are arranged in sequence along the conveying direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com