Manufacturing process and equipment for hypernormal-size conformal curved surface reflecting plate

A technology of curved surface reflection and manufacturing process, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of difficult to guarantee dimensional accuracy, difficult conformal reflector, long processing and manufacturing length, etc., achieving good versatility and saving. Material cost, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

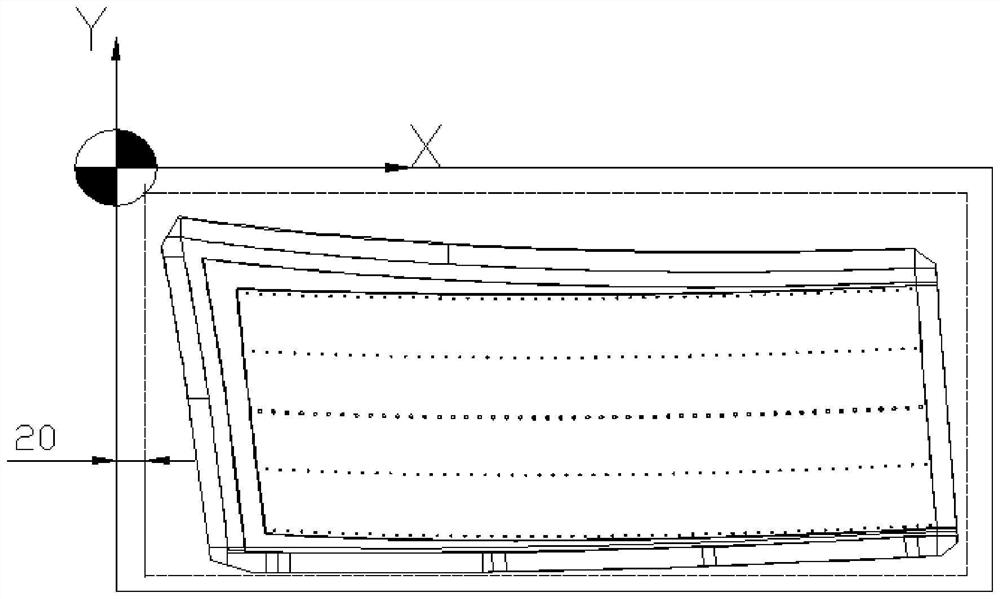

[0069] Such as figure 1 As shown, 7050 high-strength aluminum plate is used as the raw material for segmental reflector processing, and margins are reserved on both sides of the part as clamping tooling and positioning references. After low-temperature heat treatment, five-axis CNC rough and fine machining, and aging stress release, the part is completed make.

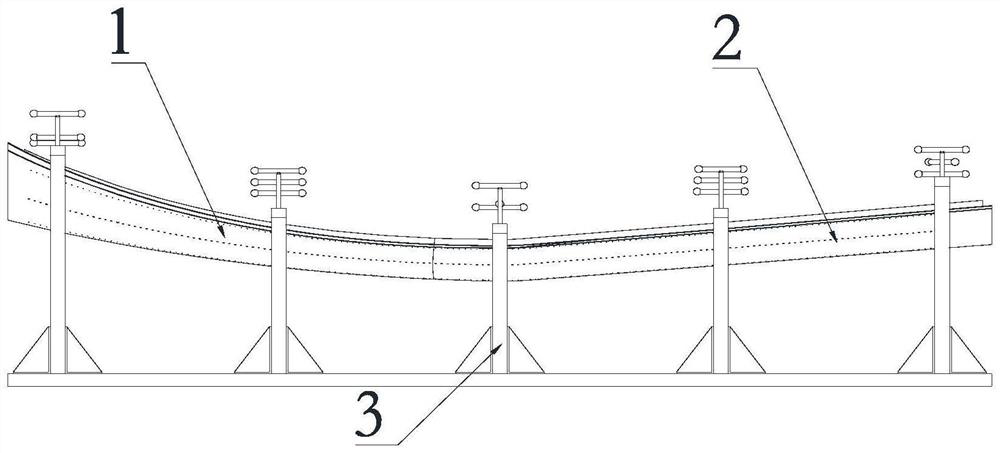

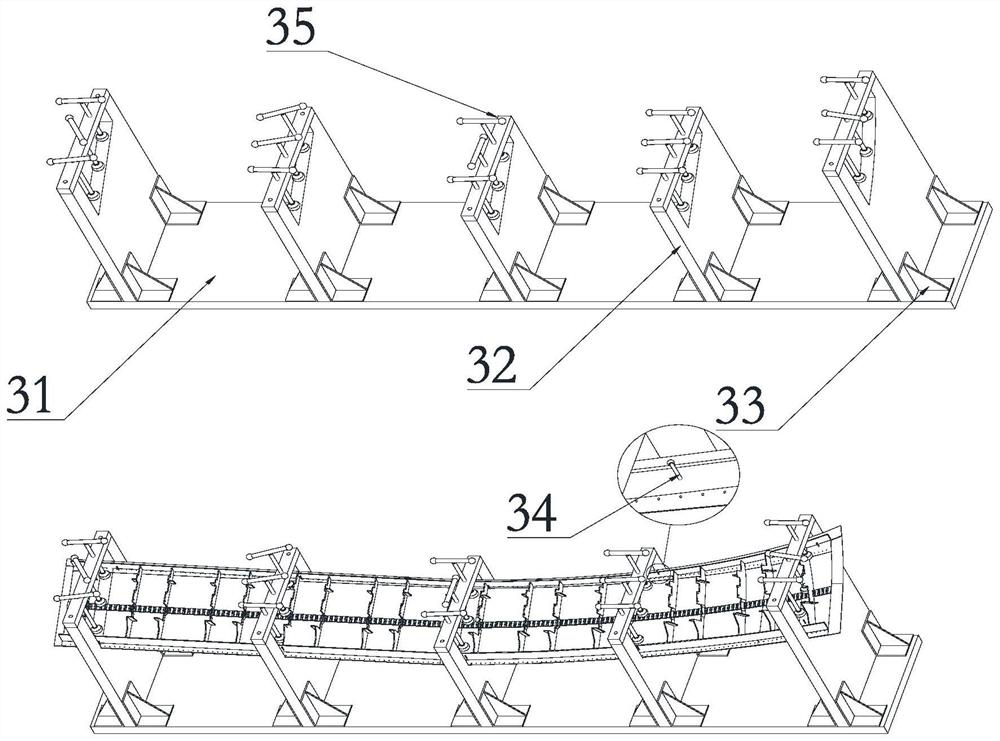

[0070] Such as Figure 1 to Figure 6 As shown, the front reflector 1, the front reflector connection mounting hole 11, the front reflector connection positioning hole 12, the rear reflector 2, the rear reflector connection installation hole 21, the rear reflector connection positioning hole 22, conformal Assembly tooling 3, tooling bottom plate 31, tooling equidistant vertical ribs 32, vertical rib fixed diagonal braces 33, reflective surface positioning pins 34, conformal tooling compression rods 35, compression beams 351, compression connecting rods 352, compression rods Handle 353, PTFE compression head 354, compr...

Embodiment 2

[0079] Such as Figure 7 As shown, a manufacturing process of a conformal curved reflector with a super-conventional size can be processed, including a conformal reflector for an unmanned aerial vehicle body. The process includes:

[0080] S1. After performing segmental CNC machining on the conformal reflector, it is realized by using conformal tooling for integral riveting connection;

[0081]S2. Combining with pre-stretched 7-series aviation aluminum specifications, the conformal reflector is designed and segmented. The segmented reflector adopts five-axis CNC machining with the machining allowance around the raw material as the clamping tire mold, and removes the margin of the main raw material. Rough machining and finishing to ensure the accuracy of the reflector, and according to the characteristics of the 7-series aluminum material, natural aging is used to eliminate the processing stress and other processes to ensure the dimensional accuracy of the segmented reflector; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com