7-hydroxyl chelating cross-linking agent and preparation method thereof

A technology of crosslinking agent and hydroxyl, which is applied in the field of 7-hydroxyl chelating crosslinking agent and its preparation, can solve the problem of few boron ions, achieve the effect of increasing content and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

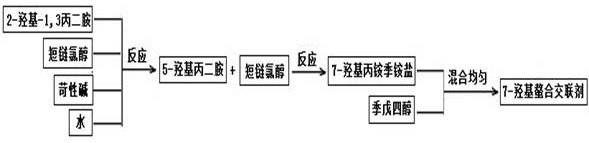

[0037] The present invention also provides a kind of preparation method of 7-hydroxyl chelating cross-linking agent, such as figure 1 shown, including the following steps:

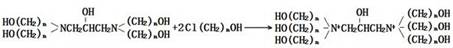

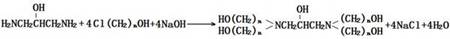

[0038] Step 1: Mix the caustic soda and water in parts by weight in agent c to obtain lye for later use, then add the short-chain chlorohydrin and lye in parts by weight in agent c to 2-hydroxyl-1,3-propylenediamine dropwise for reaction to obtain 5-hydroxypropylenediamine;

[0039] Step 2: Continue to drop short-chain chlorohydrins in the aqueous solution of 5-hydroxypropylenediamine obtained in step 1 to react, and obtain 7-hydroxypropylenediammonium quaternary ammonium salt after the dropwise reaction, wherein the 5-hydroxypropylenediamine The mass ratio of diamine aqueous solution and the short-chain chlorohydrins added dropwise is 1000:160-218;

[0040] Step 3: Mix the 7-hydroxypropylene diammonium quaternary ammonium salt obtained in step 2 with pentaerythritol in a mass ratio of 10:1-3 to obtain a...

Embodiment 1

[0057] Add 362Kg of demineralized water into the container A equipped with agitator, start the agitator, add 224Kg of potassium hydroxide until completely dissolved, then transfer the lye to the head tank B2 for standby.

[0058] Add 324Kg of chloroethanol to the head tank B1 for later use.

[0059] Add 90Kg of 2-hydroxyl-1,3-propylenediamine to reactor B equipped with agitator, heating system and cooling system, heat to 42°C, start the agitator, open the valve of head tank B1, and dropwise add Chlorohydrin, the dropping rate is 1-2 liters / minute. After 30 minutes of dropwise addition, open the valve of head tank B2, and dropwise add lye to reactor B at a rate of 1.5-3 liters / minute. During the dropping process, when the temperature reaches 50°C, turn on the cooling system for cooling, and control the temperature between 45°C and 55°C. The chloroethanol was dripped before the lye, and the total time for the dropwise addition was 227 minutes; the time for the lye dropwise was...

Embodiment 2

[0067] Add 426Kg of demineralized water into the container A equipped with agitator, start the agitator, add 160Kg of sodium hydroxide to completely dissolve, then transfer the prepared lye to the head tank B2 for subsequent use.

[0068] Add 324Kg of chloroethanol to the head tank B1 for later use.

[0069] Add 90Kg of 2-hydroxyl-1,3-propylenediamine to reactor B equipped with agitator, heating system and cooling system, heat to 42°C, start the agitator, open the valve of head tank B1, and dropwise add Chlorohydrin, the dropping rate is 1-2 liters / minute. After 30 minutes of dropwise addition, open the valve of head tank B2, and dropwise add lye to reactor B at a rate of 1.5-3 liters / minute. During the dropping process, when the temperature reaches 50°C, turn on the cooling system for cooling, and control the temperature between 45°C and 55°C. The chloroethanol was dripped before the lye, and the time for the dropwise addition was 200 minutes in total; the time for the lye ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com