Low-dielectric low-loss Ba-Si-B-M-based LTCC material and preparation method thereof

A ba-si-b-m, low-loss technology, applied in the field of electronic information ceramics and its manufacturing, achieves the effects of low dielectric loss, simple preparation process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

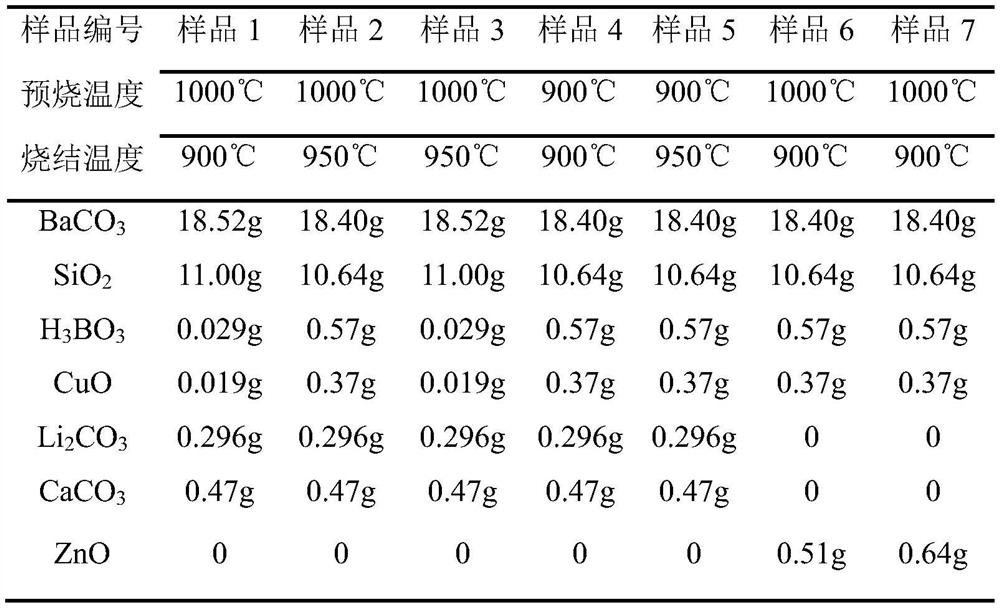

[0018] According to the general chemical formula BaSi in the embodiment 2 B x m y o 5 (Wherein M is Li, Ca and / or Zn of metal cation, x=0.05~0.2mol, y=0.05~0.09mol) carry out batching, raw material is BaCO 3 , SiO 2 , Li 2 CO 3 , CaCO 3 , CuO, ZnO and H 3 BO 3 . The material of the present invention is prepared by solid-state reaction, and the specific preparation steps are consistent with the steps of the above-mentioned content of the invention.

[0019]

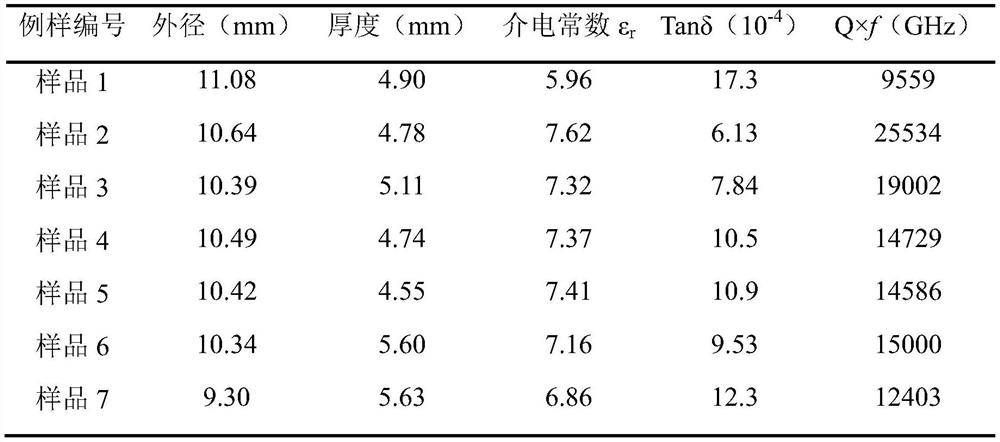

[0020] Microwave dielectric properties of samples 1-7 at the optimum sintering temperature:

[0021]

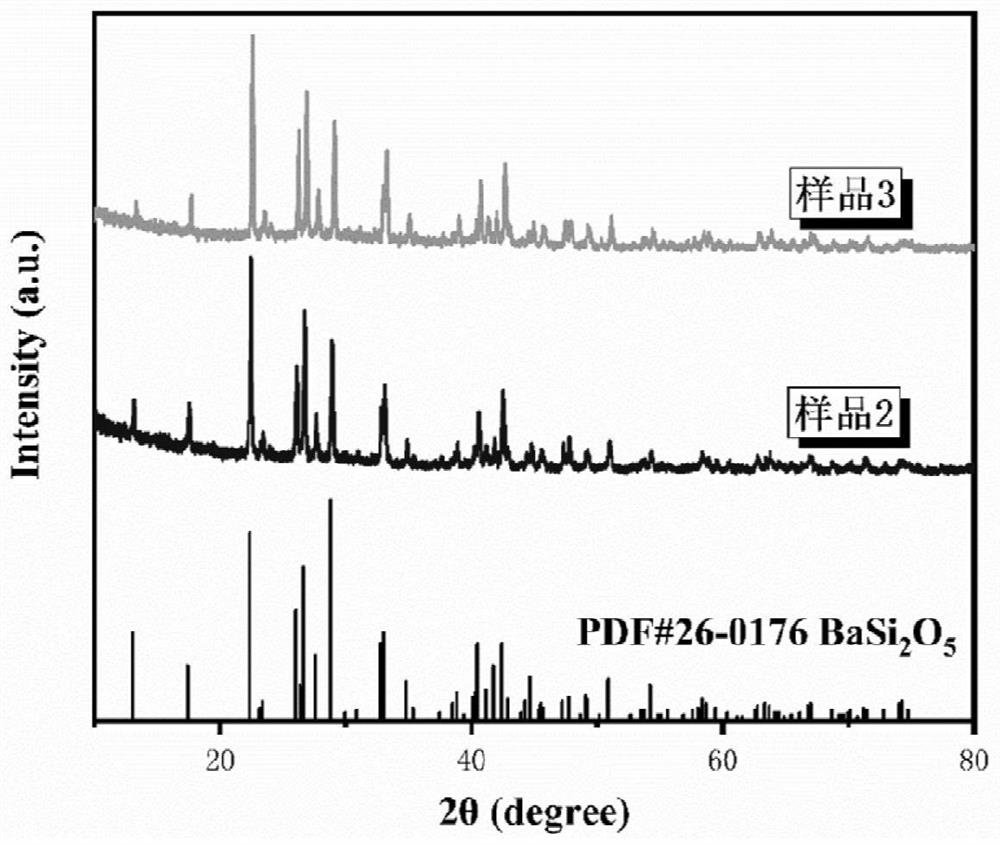

[0022] figure 1 Be the XRD diffraction pattern of embodiment 2,3 sample ceramic material, from figure 1 It can be seen that the main crystal phase is BaSi 2 o 5 (PDF#26-0176), no secondary phase, ensuring excellent dielectric and mechanical properties of the ceramic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com