Preparation method of 1, 4-cyclohexanedicarboxylic acid

A technology of cyclohexanedicarboxylic acid and terephthalic acid, which is applied in chemical instruments and methods, preparation of carboxylic acids by ozone oxidation, catalysts for physical/chemical processes, etc., can solve problems such as poor activity and selectivity, and achieve long service life, High hydrogenation activity and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

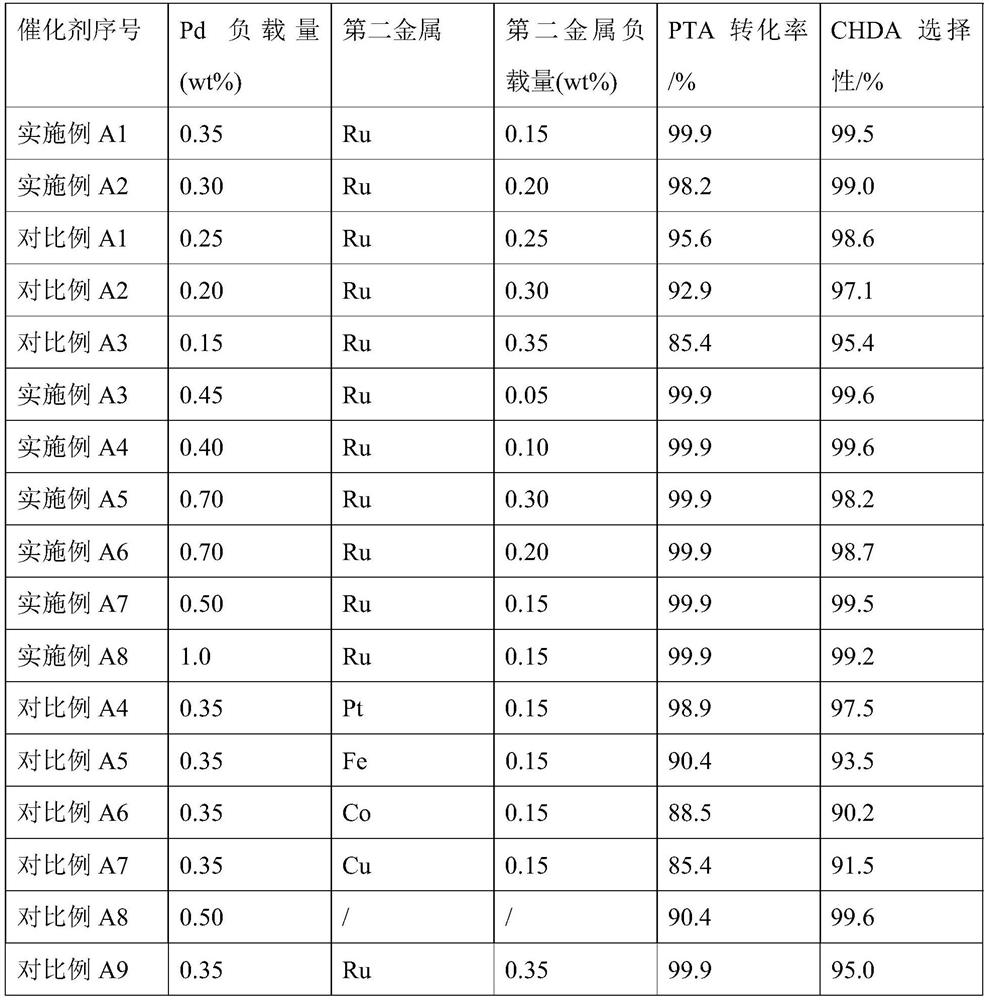

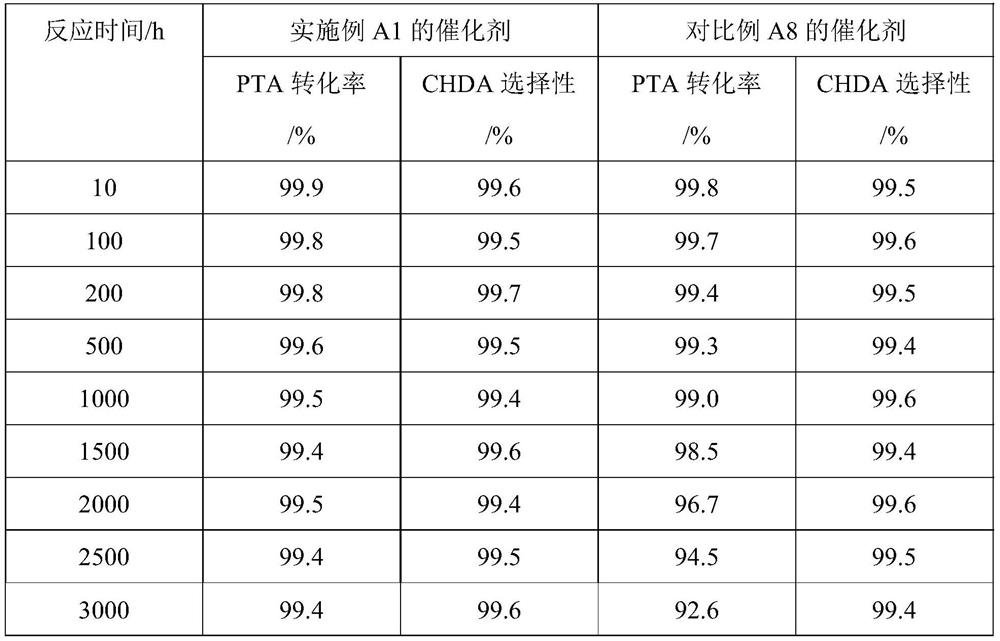

Examples

Embodiment A1

[0025] Example A1: The columnar activated carbon carrier was pretreated with a nitric acid solution, the nitric acid concentration was 5.0 wt%, the mass ratio of the activated carbon carrier to the nitric acid solution was 1:5, the treatment temperature was 90°C, and the treatment time was 3h. After nitric acid pretreatment, the activated carbon carrier was washed with purified water until the filtrate was neutral, and dried at 110 °C for 4 h.

[0026] The catalyst was prepared by an equal volume impregnation method. Palladium chloride and ruthenium chloride solutions (dissolved in hydrochloric acid) were prepared according to the theoretical loading, and the activated carbon carrier treated with the above nitric acid was added, impregnated for 24 hours, and dried at 110 °C for 4 hours. Using hydrogen reduction, the reduction temperature is 300 ℃. The theoretical loading of metal Pd is 0.35 wt %, and the theoretical loading of metal Ru is 0.15 wt %.

[0027] In Examples A2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com