Separation and extraction method of soil humus

An extraction method and technology for humic substances, which are applied in the field of humic substance biochemistry research, can solve the problems of hydrolysis and oxidation of some organic substances, and achieve the effects of simple operation, avoiding changes in chemical structure and properties, and convenient correlation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

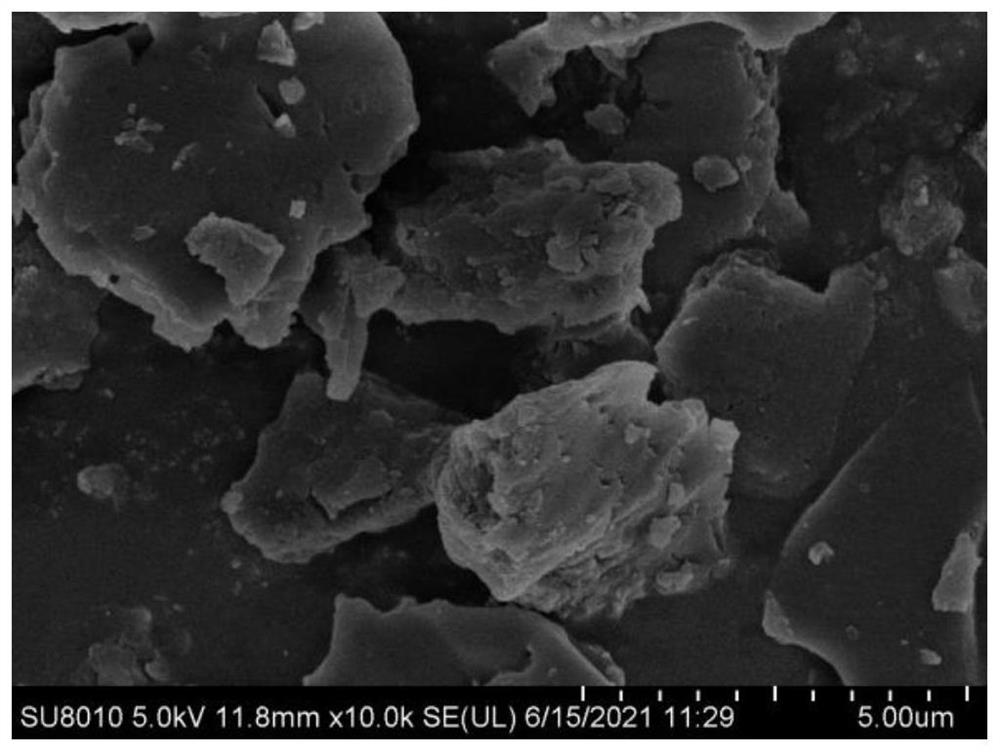

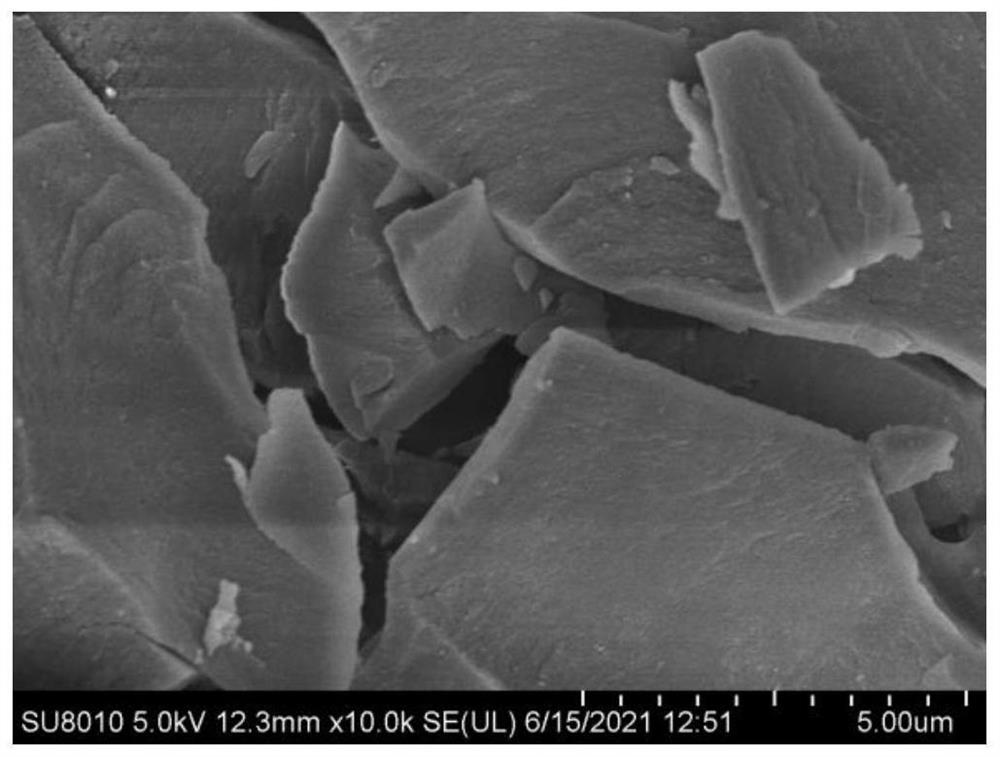

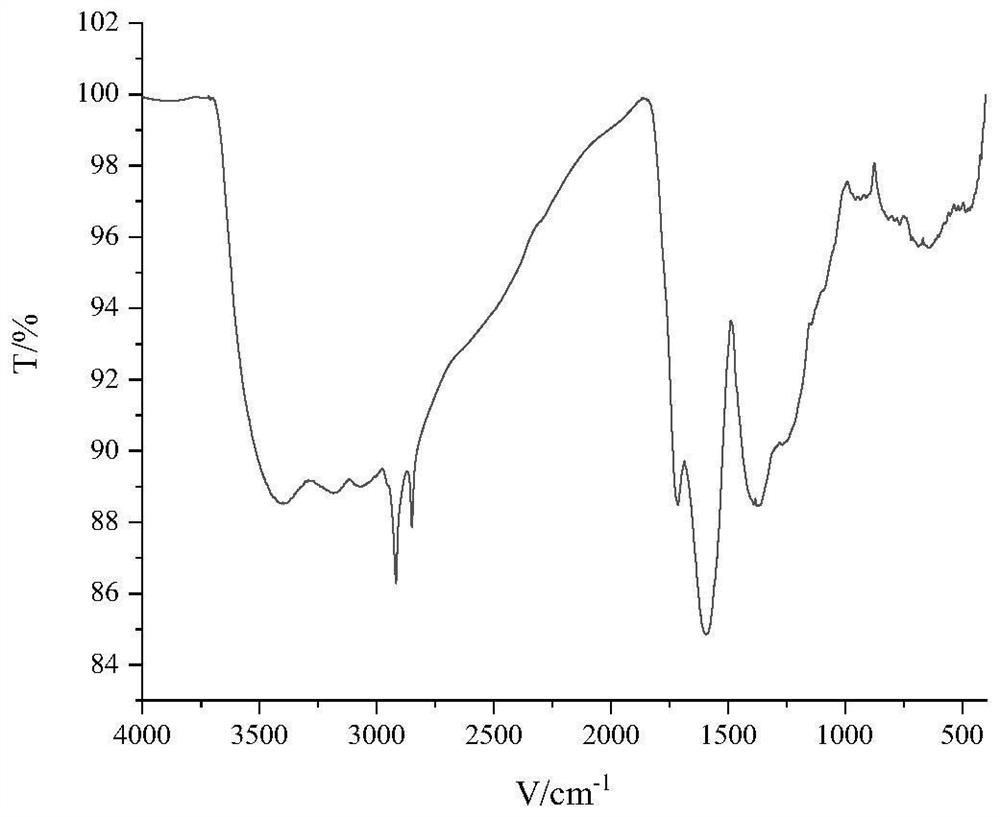

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the separation and extraction method of a kind of soil humus in this embodiment: the soil sample is dissolved in the mixture of acetone and hydrochloric acid, filtered, and the filtrate is diluted with distilled water to obtain the precipitation of humic acid, and the supernatant is treated with hydrogen The sodium oxide solution was titrated to obtain the precipitate of humin, then the humic acid and humin were purified separately, and finally freeze-dried to obtain the dry matter of humic acid and humin.

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the separation and extraction method of a kind of soil humus is carried out according to the following steps:

[0023] 1. Dissolve the soil sample in the mixed solution of acetone and hydrochloric acid, fully shake and dissolve, overnight, and take the filtrate after filtering;

[0024] 2. Dilute the filtrate to 2 times the original volume with distilled water, let stand overnight, centrifuge to obtain humic acid precipitate, titrate the supernatant to neutral with sodium hydroxide solution, let stand overnight, and centrifuge to obtain humin precipitate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mixture of acetone and hydrochloric acid described in step 1 is composed of acetone and hydrochloric acid with a mass concentration of 10% in a mass ratio of 9:1. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com