High-performance pipe and preparation method thereof

A high-performance, pipe material technology, applied in the field of power tubes, can solve the problems of poor antistatic performance of power tubes, achieve the effects of reducing material resistivity, improving pipe strength, and improving antistatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

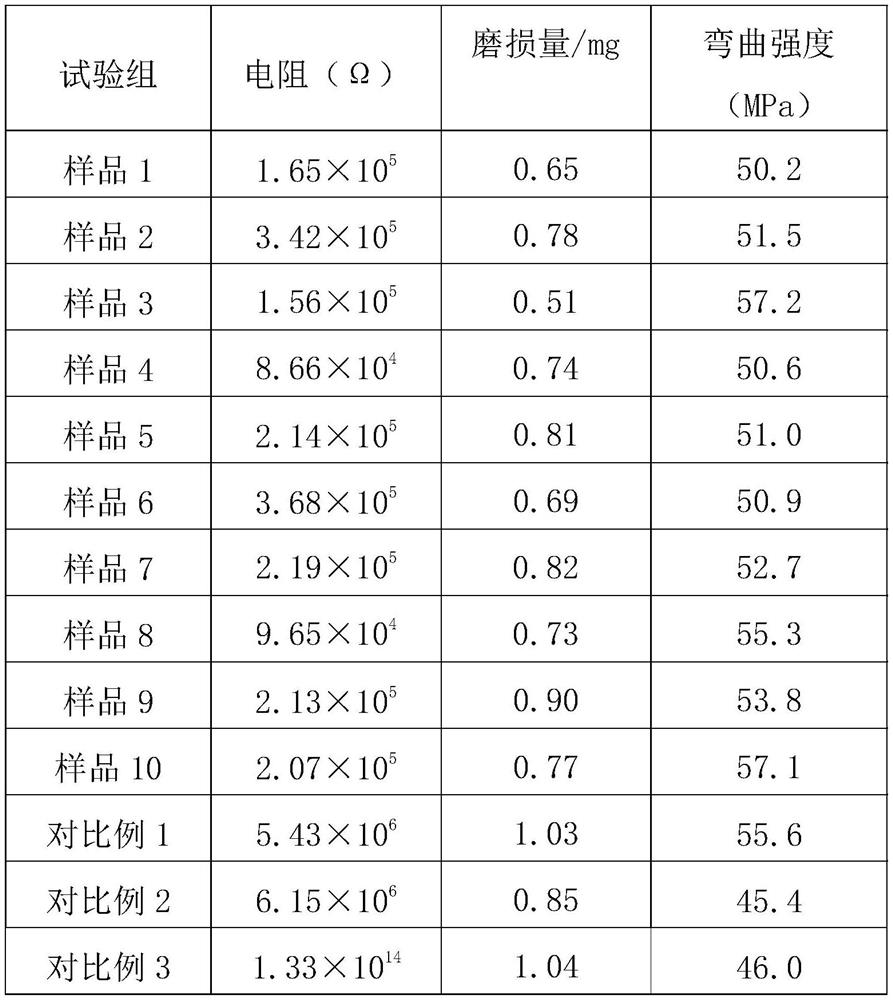

Examples

Embodiment 1

[0047] A high performance tubing containing polypropylene, graphene oxide grafted styrene and fluorinated graphite.

[0048] This high performance tubing also contains impact modifiers, calcium carbonate, antioxidants and wetting agents.

[0049] In parts by weight,

[0050] Polypropylene: 50 to 120 parts;

[0051] Graphene oxide grafted with styrene: 0.5 to 5 parts;

[0052] Graphite fluoride: 0.5 to 5 parts;

[0053] Impact modifier: 10 to 30 parts;

[0054] Antioxidant: 1 to 3 parts;

[0055] Calcium carbonate: 2 to 10 parts:

[0056] Wetting agent: 1 to 4 parts.

[0057] Wherein, the wetting agent is composed of sorbitan triisostearate, glycerin and chlorinated paraffin. The impact modifier of the present invention is methyl methacrylate-butadiene-styrene, styrene copolymer and chlorinated polyethylene. The antioxidant was pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

[0058] It should be noted that the graphene oxide-grafted styrene a...

Embodiment 2

[0062] A high performance tubing containing polypropylene, graphene oxide grafted styrene and fluorinated graphite.

[0063] This high performance tubing also contains impact modifiers, calcium carbonate, antioxidants and wetting agents.

[0064] In parts by weight,

[0065] Polypropylene: 70 to 100 parts;

[0066] Graphene oxide grafted with styrene: 1 to 3 parts;

[0067] Graphite fluoride: 2 to 3 parts;

[0068] Impact modifier: 15 to 25 parts;

[0069] Antioxidant: 1.5 to 2.3 parts;

[0070] Calcium carbonate: 4 to 6 parts;

[0071] Wetting agent: 2 to 3 parts.

[0072] Wherein, the wetting agent is composed of sorbitan triisostearate, glycerin and chlorinated paraffin. The impact modifier of the present invention is methyl methacrylate-butadiene-styrene, styrene copolymer and chlorinated polyethylene. The antioxidant was pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

[0073] The weight ratio in the wetting agent is, sorbitan triisostea...

Embodiment 3

[0076] A high performance tubing containing polypropylene, graphene oxide grafted styrene and fluorinated graphite.

[0077] This high performance tubing also contains impact modifiers, calcium carbonate, antioxidants and wetting agents.

[0078] In parts by weight,

[0079] Polypropylene: 85.9 parts;

[0080] Graphene oxide grafted styrene: 2.6 parts;

[0081] Graphite fluoride: 2.1 parts;

[0082] Impact modifier: 18.5 parts;

[0083] Antioxidant: 1.8 parts;

[0084] Calcium carbonate: 5.3 parts;

[0085] Wetting agent: 2.2 parts.

[0086] Wherein, the wetting agent is composed of sorbitan triisostearate, glycerin and chlorinated paraffin. The impact modifier of the present invention is methyl methacrylate-butadiene-styrene, styrene copolymer and chlorinated polyethylene. The antioxidant was pentaerythritol tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate.

[0087] The weight ratio in the wetting agent is, sorbitan triisostearate: glycerin: chlorinated paraffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com