Draw-texturing sea-island filament and production process thereof

A production process and technology of sea-island silk, which is applied in rayon manufacturing, filament/thread forming, conductive/antistatic filament manufacturing, etc. Improve the effect of antistatic effect and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

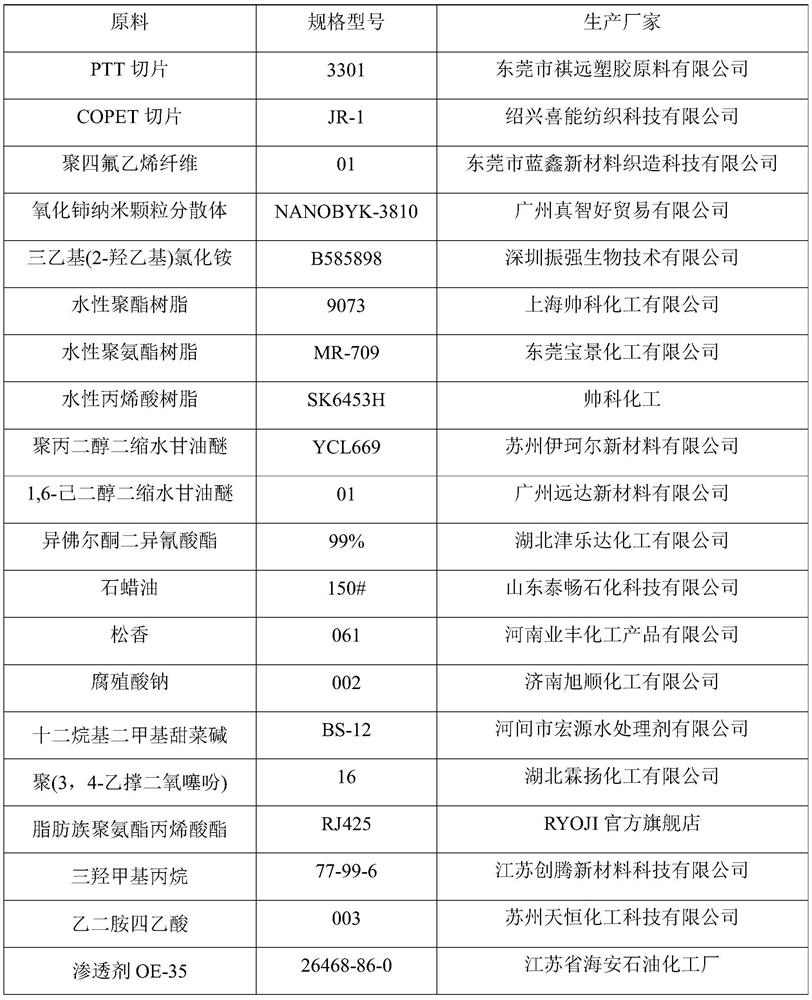

preparation example Construction

[0051] Wherein, the preparation method of the oil agent comprises the following steps: mixing and stirring paraffin oil, rosin, sodium humate and dodecyl dimethyl betaine evenly.

[0052] Wherein, the winding speed of winding in step (3) is 3400m / min.

[0053] Preferably, the COPET chip is an alkali-soluble polyester chip with a water content of 0.6%, a melting point of 240° C., an intrinsic viscosity of 0.65 dL / g, and a terminal group of 40 mol / t.

[0054] Preferably, the average particle diameter of the polytetrafluoroethylene fibers is 400D.

[0055] Preferably, the model of the cerium oxide nanoparticle dispersion is NANOBYK-3810, the nanoparticle content is 18%, and the particle size is D50nm.

[0056] Preferably, the purity of triethyl(2-hydroxyethyl)ammonium chloride is 98%, and the CAS number is 152-22-7.

[0057] Preferably, the solid content of the water-based polyester resin is 75%.

[0058] Preferably, the waterborne polyurethane resin has a solid content of 45%...

Embodiment 1

[0075] In this embodiment, elastic sea-island silk is made of the following raw materials: 70kg of PTT slices, 30kg of COPET slices, 30kg of polytetrafluoroethylene fibers, 5kg of cerium oxide nanoparticle dispersions, and 10kg of modified antistatic agents. The electrostatic agent is made from triethyl (2-hydroxyethyl) ammonium chloride through water-based resin and cross-linking agent. The mass ratio of triethyl (2-hydroxyethyl) ammonium chloride, water-based resin and cross-linking agent It is 10:5:6, the water-based resin is composed of water-based polyester resin and water-based polyurethane resin in a mass ratio of 1:1, and the cross-linking agent is composed of poly(propylene glycol) diglycidyl ether, 1,6-hexanediol diglycidyl ether Composition by mass ratio 1:1.

[0076] The production process of the present embodiment adding elastic island-in-the-sea silk comprises the following steps:

[0077] (1) Crystallize the PTT chip at 155°C, then add polytetrafluoroethylene f...

Embodiment 2-5

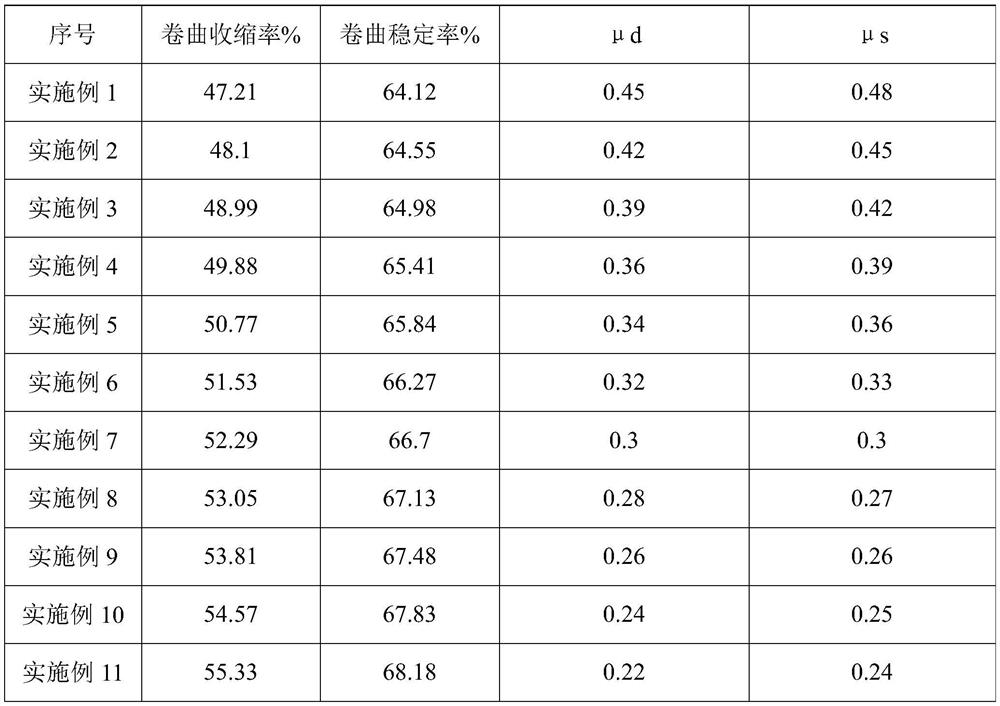

[0083] Examples 2-5 respectively provide textured island-in-the-sea yarns with different ratios of raw material components. The ratio of raw material components of the textured island-in-the-sea yarns corresponding to each embodiment is shown in Table 2, and the unit of raw material ratio is kg.

[0084] Table 2 embodiment 1-5 raw material ratio

[0085] raw material Example 1 Example 2 Example 3 Example 4 Example 5 PTT slice 70 80 75 74 76 COPET slice 30 40 35 34 36 PTFE fiber 30 40 35 35 35 Cerium Oxide Nanoparticle Dispersion 5 10 8 8 8 Modified antistatic agent 10 20 15 14 16 Paraffin oil 9 15 12 12 12 rosin 10 20 15 15 15 humic acid 16 20 18 18 18 Lauryl dimethyl betaine 6 8 7 7 7

[0086] The difference between Examples 2-5 and Example 1 lies in that the raw material ratio of each component of the textured island-in-the-sea yarn is different, and the others are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com