Antistatic flame-retardant polypropylene material and preparation method thereof

A flame retardant polypropylene, antistatic technology, applied in the field of antistatic flame retardant polypropylene material and its preparation, can solve the problems of complex mechanism, unpredictable and inference, and achieve the effect of improving impact strength and antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

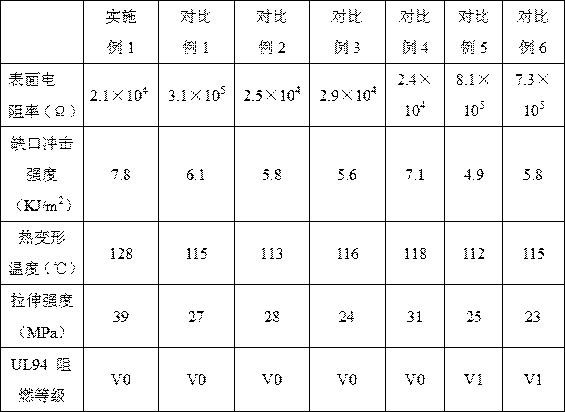

Examples

Embodiment 1

[0028] An antistatic flame retardant polypropylene material, made of the following raw materials in parts by weight: 78 parts of PP resin, 10 parts of antistatic agent, 10 parts of POE resin, 0.1 part of PETS, 0.2 parts of diffusing oil, and 1.2 parts of zinc stearate , 0.8 parts of antioxidant, 15 parts of filler, 3 parts of impact modifier, 3 parts of flame retardant, 0.1 part of slip agent and 0.03 part of pigment powder;

[0029] The antistatic agent is a mixture of antistatic agent H95 and antistatic agent 3500 in a weight ratio of 3:1;

[0030] The PP resin has a density of 0.92g / cm 3 , Copolymerized polypropylene with a melting point of 167°C;

[0031] The POE resin is an ethylene-octene copolymer with an octene monomer content of 25%;

[0032] The PETS is a mixture composed of PETS-3 with a hydroxyl value of 60mgKOH / g and a melting point of 55°C and PETS-4 with a hydroxyl value of 30mgKOH / g and a melting point of 60°C in a weight ratio of 1:1.5;

[0033] The diffusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com